Anticorrosive coating and preparation method thereof

A technology of anti-corrosion coatings and pigments, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as large differences in corrosion resistance and corrosion of substrates, and achieve balanced corrosion resistance, reduce losses, and save The effect of oil resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

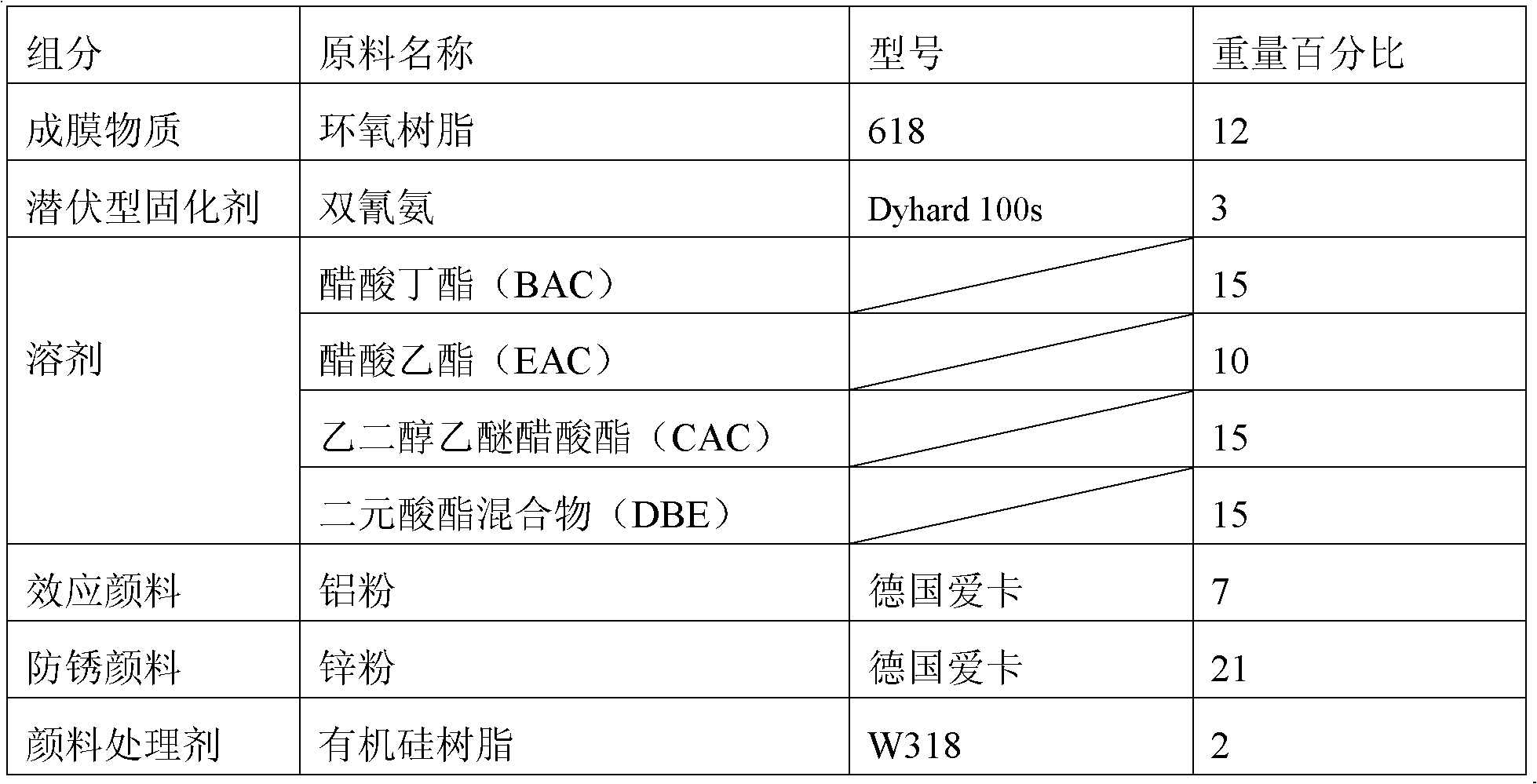

[0043] (embodiment 1, anticorrosion coating)

[0044] The anti-corrosion coating of this embodiment can be used in indoor environment, and is made up of film-forming substance, curing agent, solvent, pigment, pigment treatment agent; Wherein film-forming substance is epoxy resin; Curing agent is latent curing agent; Solvent comprises acetic acid Butyl ester, ethyl acetate, glycol ether acetate and dibasic acid ester mixture; pigments include effect pigments and anti-rust pigments; pigment treatment agent is silicone resin. The specific raw materials and proportioning are shown in Table 1:

[0045] Table I

[0046]

[0047] Of course, other types of epoxy resin, dicyandiamide, and silicone resin can also be used, and domestic aluminum powder and zinc powder can also be used.

Embodiment 2

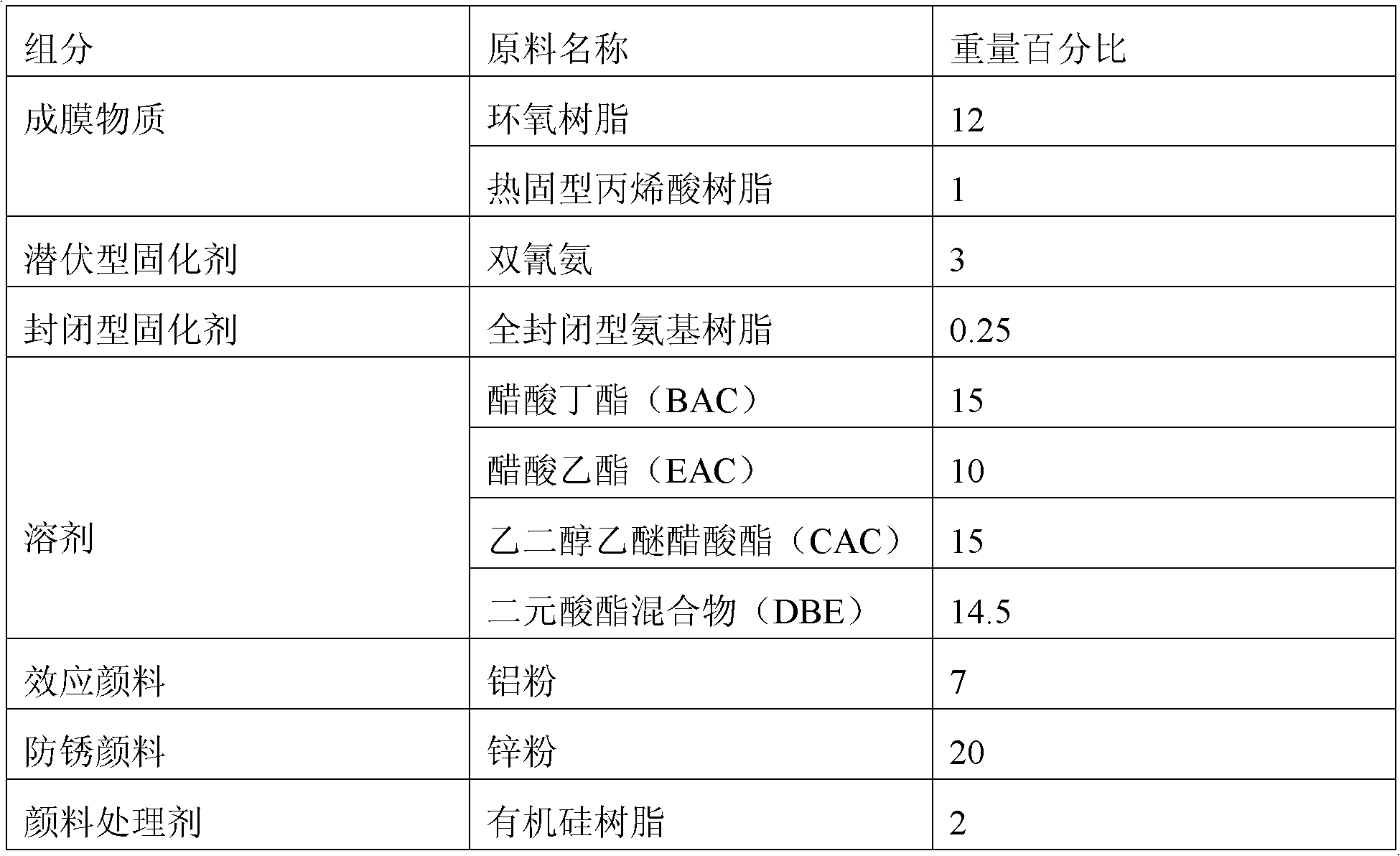

[0048] (embodiment 2, anticorrosion coating)

[0049] The raw materials and models used in this embodiment are all the same as in Example 1, the difference is that the ratio of raw materials is carried out according to Table 2:

[0050] Table II

[0051] raw material name

Embodiment 3

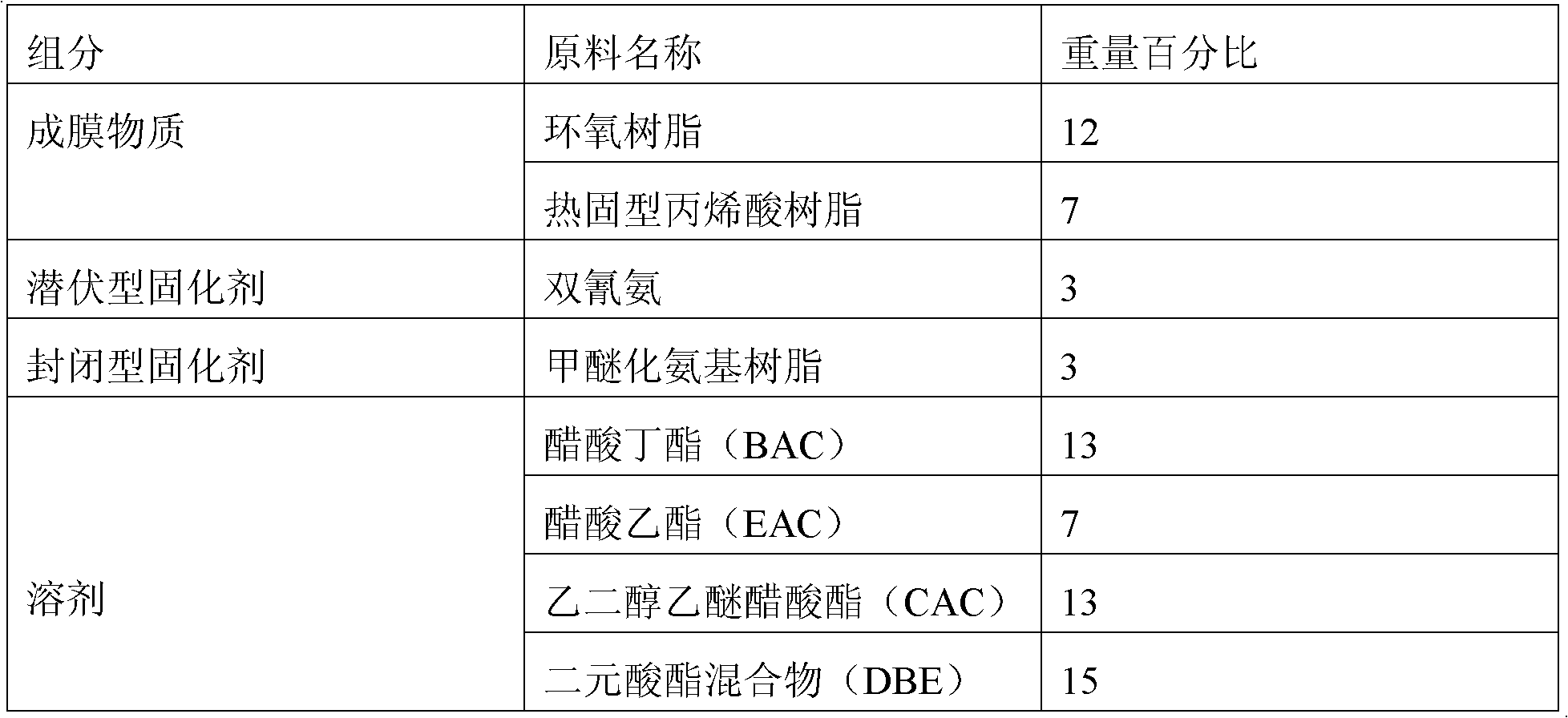

[0052] (embodiment 3, anticorrosion coating)

[0053] The raw materials and models used in this embodiment are all the same as in Example 1, the difference being that the ratio of raw materials is carried out according to Table 3:

[0054] Table three

[0055] raw material name

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com