Water processor with uniform magnetic gaps

A water processor and magnetic gap technology, which is applied in the field of water processors where the magnetic gap is homogeneous, can solve the problems such as the inability to obtain a uniform magnetic water flow cutting method, and the inability to achieve the vertical cutting of the magnetic field lines by the water flow, and achieve a small gap between the magnets and uniform magnetic flux. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

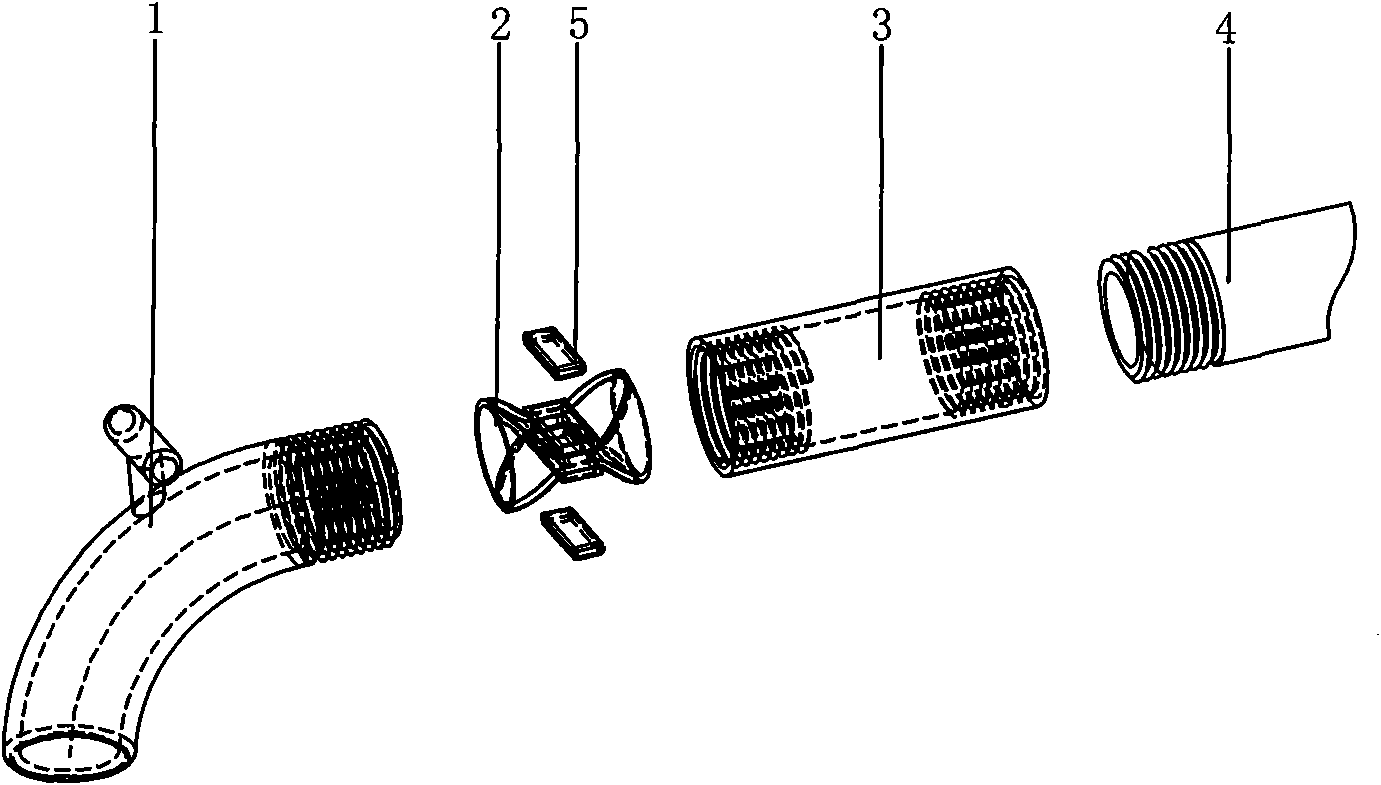

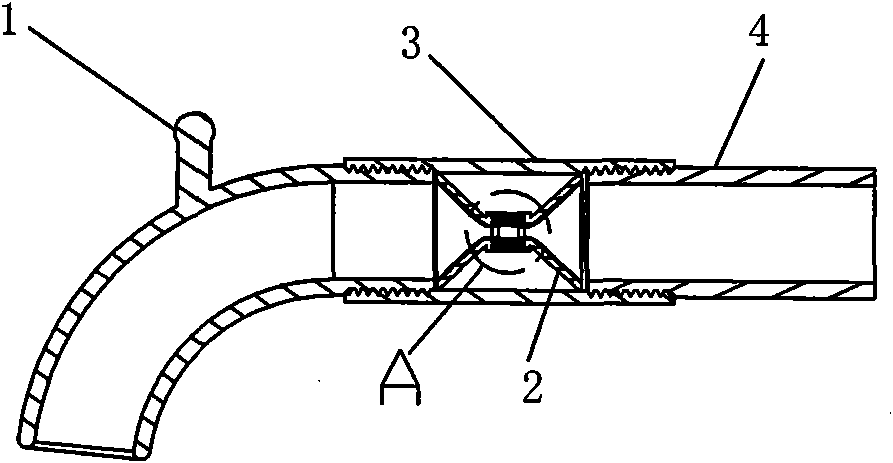

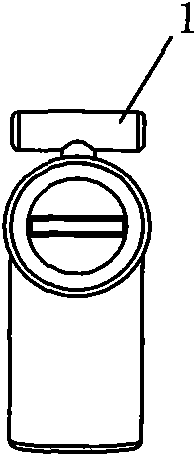

[0028] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , a kind of magnetic gap of the present invention is the water processor of homogenization, is made up of faucet 1, magnet fixing frame-2, connector outer pipe 3, water pipe 4, rectangular parallelepiped magnet 5, wherein, magnet fixing frame-2 is a dumbbell shaped water pipe, the middle part of the dumbbell-shaped water pipe is a flat-shaped pipe, and there are pits at the upper and lower ends of the flat-shaped pipe. In the pit, the dumbbell-shaped water pipe is sleeved in the connector outer pipe 3, and one end of the connector outer pipe 3 is threaded with the water tap 1, and the other end is threaded with the water pipe 4. Turn on the water tap, and the water flow passes through the dumbbell-shaped water pipe. Since the distance between the two cuboid-shaped magnets 5 in the middle of the dumbbell-shaped water pipe is controlled between 1 mm and 3 mm in implementation, the distance between the two cuboi...

Embodiment 2

[0030] Example 2, participate in Figure 5 , Figure 6 , Figure 7 , Figure 8 , a kind of magnetic gap of the present invention is the water processor of homogenization, is made up of faucet 1, magnet fixing frame 2 8, connector outer pipe 3, water pipe 4, annular magnet 6, cylindrical magnet 7, wherein, magnet fixing frame 2 8 is a cylinder, the cylinder is provided with 3 poles, the ring magnet 6 is placed in the cylinder, the cylindrical magnet 7 is fixed on the 3 poles in the cylinder, and the magnet fixing frame 2 8 is sleeved on the In the connector outer pipe 3, one end of the connector outer pipe 3 is threaded with the water tap 1, and the other end is threaded with the water pipe 4. Turn on the faucet, and the water flow passes through the gap between the ring magnet 6 and the cylindrical magnet 7. Since the gap between the ring magnet 6 and the cylindrical magnet 7 is controlled between 1 mm and 3 mm in implementation, the ring magnet of the present embodiment 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com