Oxygen content detection system

A detection system and technology for oxygen content, which are applied in the fields of tobacco preparation, application, and tobacco, can solve the problems of inability to detect the vapor concentration of the process air flow, and inability to detect the high temperature process air flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

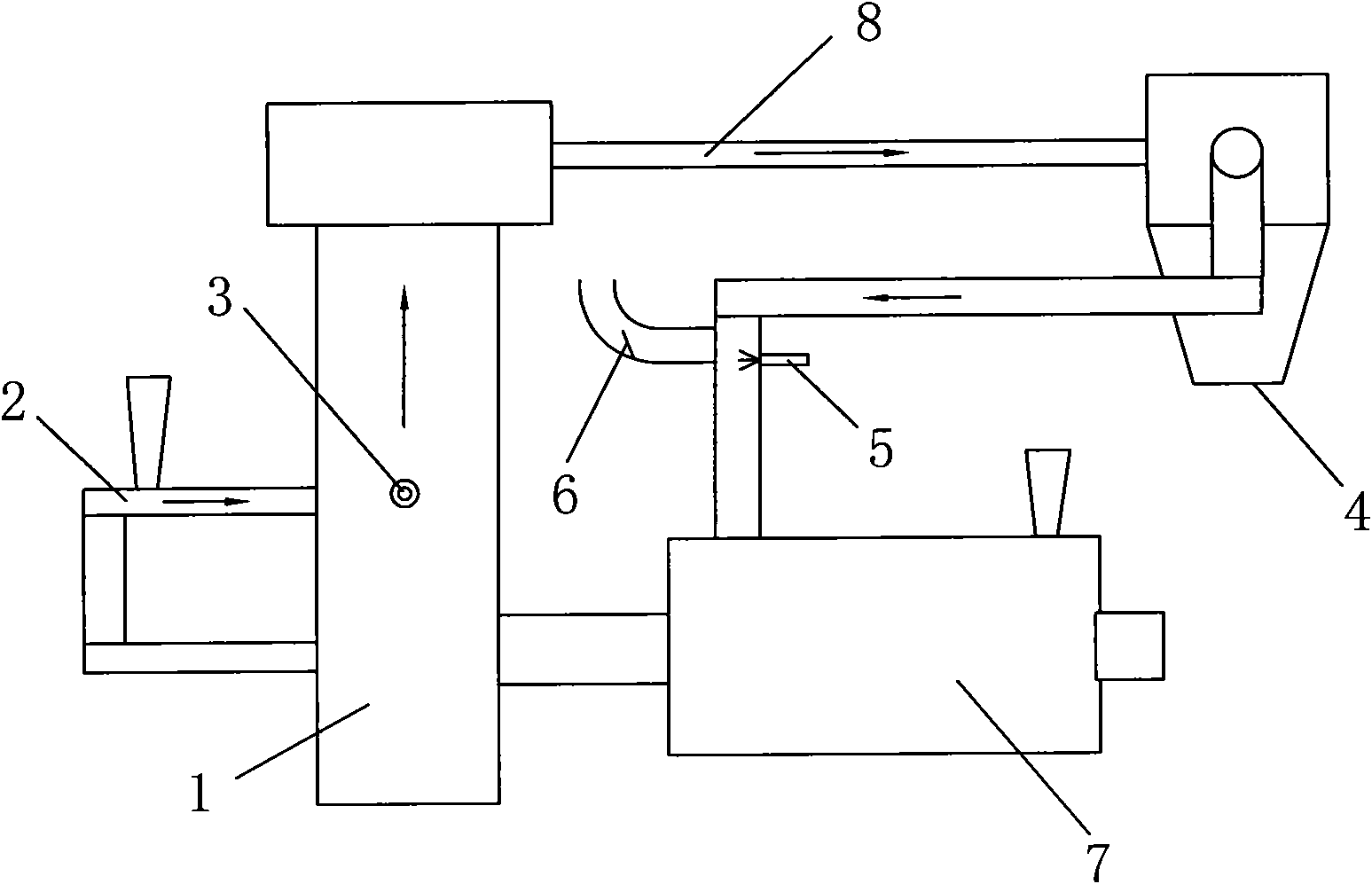

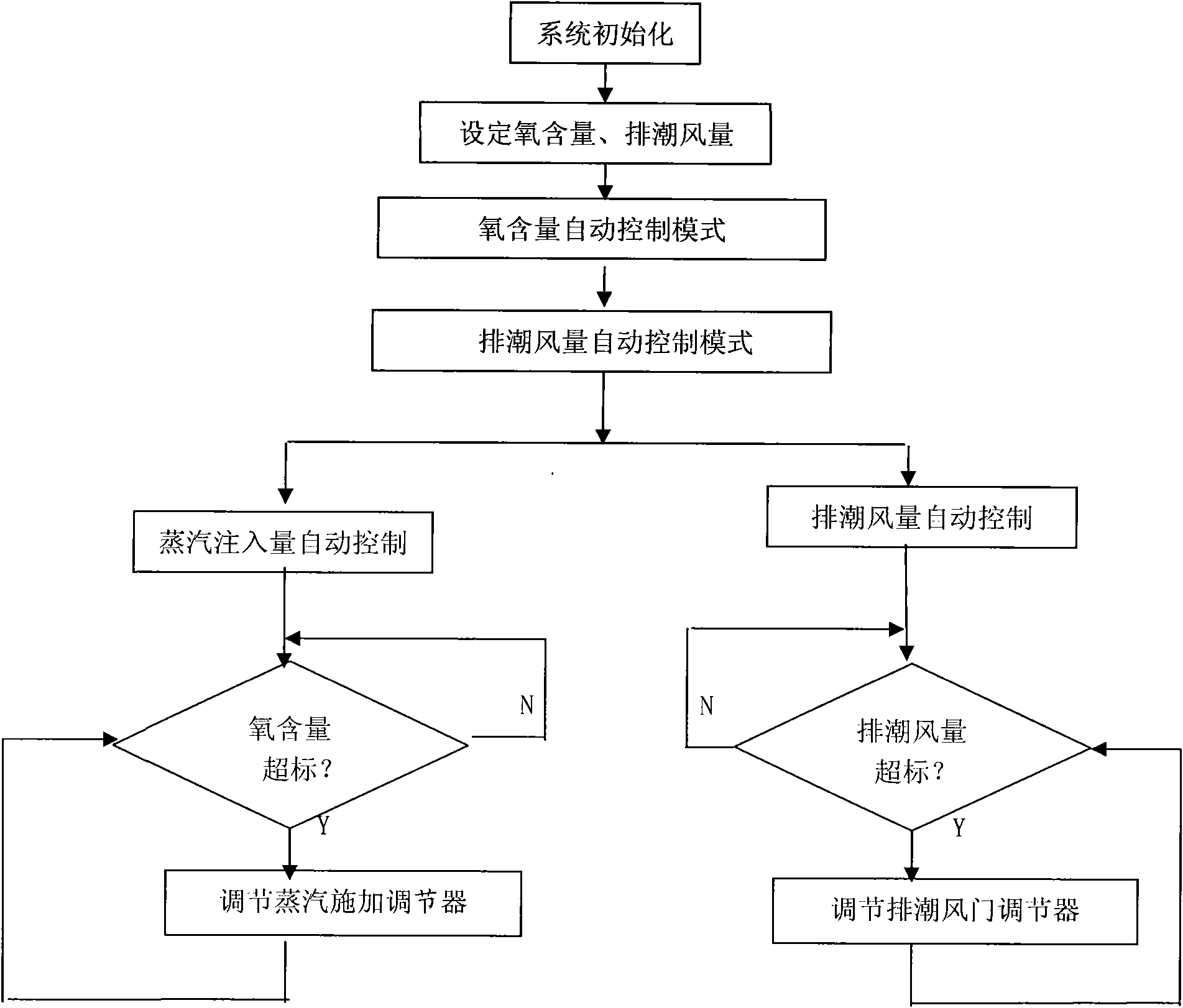

[0013] Now illustrate the present invention in conjunction with accompanying drawing and embodiment.

[0014] With the continuous development of tobacco technology, the requirements for tobacco product processing technology are getting higher and higher, and the result inspection of tobacco product in process is gradually replaced by the control of process parameters of tobacco product in process. In order to achieve the stability of the inherent quality of cigarette products, not only the accuracy of the formula must be ensured on the raw materials, but also the stability of the technological parameters in the processing process must be ensured. Only in this way can the stability of the final product quality be guaranteed. By discussing the airflow theory of the high-temperature air-flow drying process of shredded silk, which is a new silk-making technology with online full-recipe expansion, the principle of high-temperature air-flow drying and the actual quantitative detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com