Assembly welding tooling for inner tube support plate of cryostat

A cryostat and support plate technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as low work efficiency, difficult operation, deformation, etc., and achieve the effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

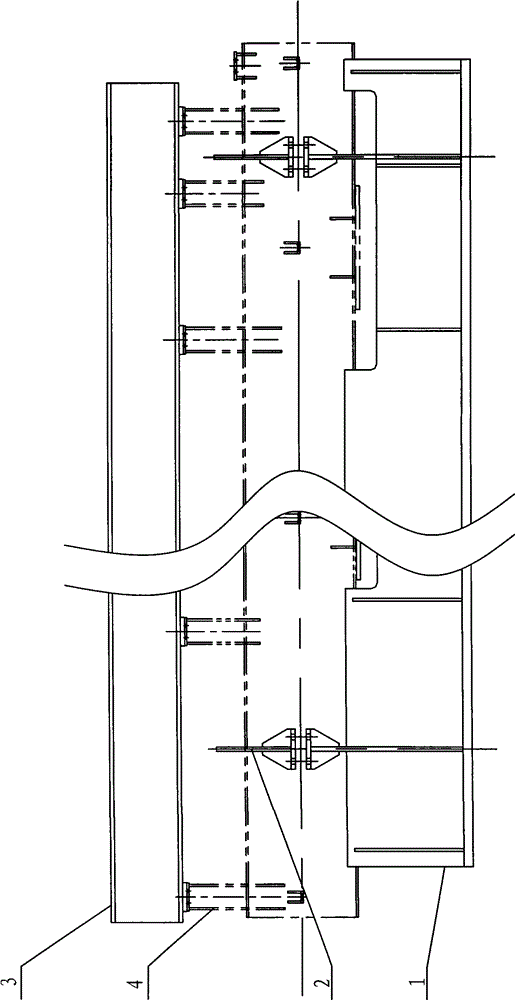

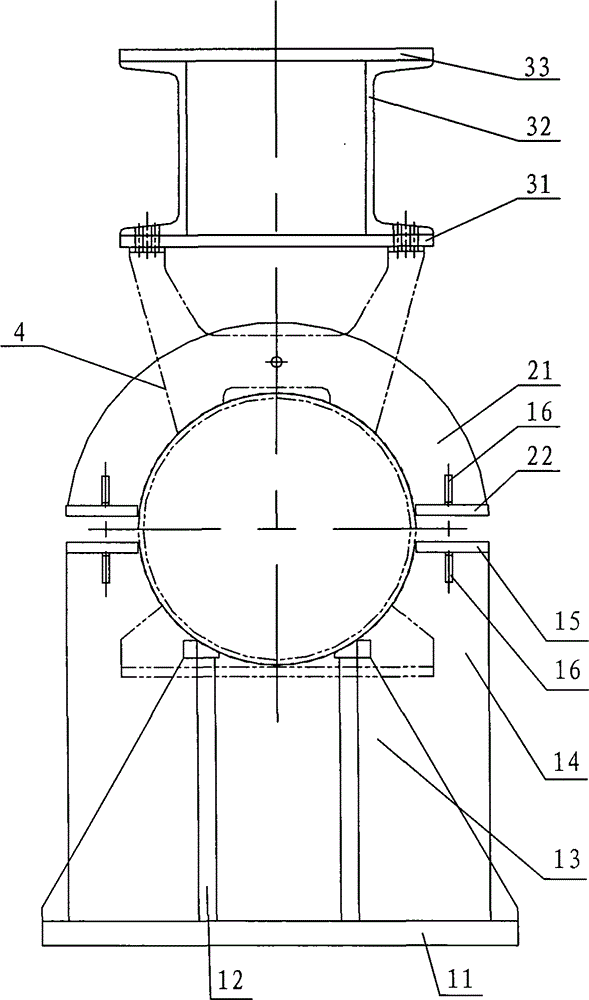

[0028] Such as figure 1 and 2 In the shown embodiment, the assembly and welding tooling of the inner tube support plate of the cryostat according to the present invention includes component I1, component II2 and component III3, component I1 and component II2 are connected by bolts, and component III3 is connected with the inner tube support plate 4 Bolt connection; assembly I1 includes a bottom plate 11 and a parallel reinforcing plate 12 welded thereon, a circular arc plate a14 whose radian is consistent with the outer diameter of the inner pipe, and the reinforcing plate 12 is arranged on the front and rear sides of the circular arc plate a14, and the reinforcing plate 12 Ribs 13 are welded on the left and right sides, support plates a15 are welded on the left and right sides of the upper end of the arc plate a14, and the two sides of the connection between the support plate a15 and the arc plate a14 are provided with reinforcing triangular plates 16; component II 2 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com