An assembly system and assembly method of a duckbill hole seeder

An assembly system and hole seeder technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as high labor costs, poor assembly accuracy, and low operating efficiency, and achieve small welding deformation and fast and flexible installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

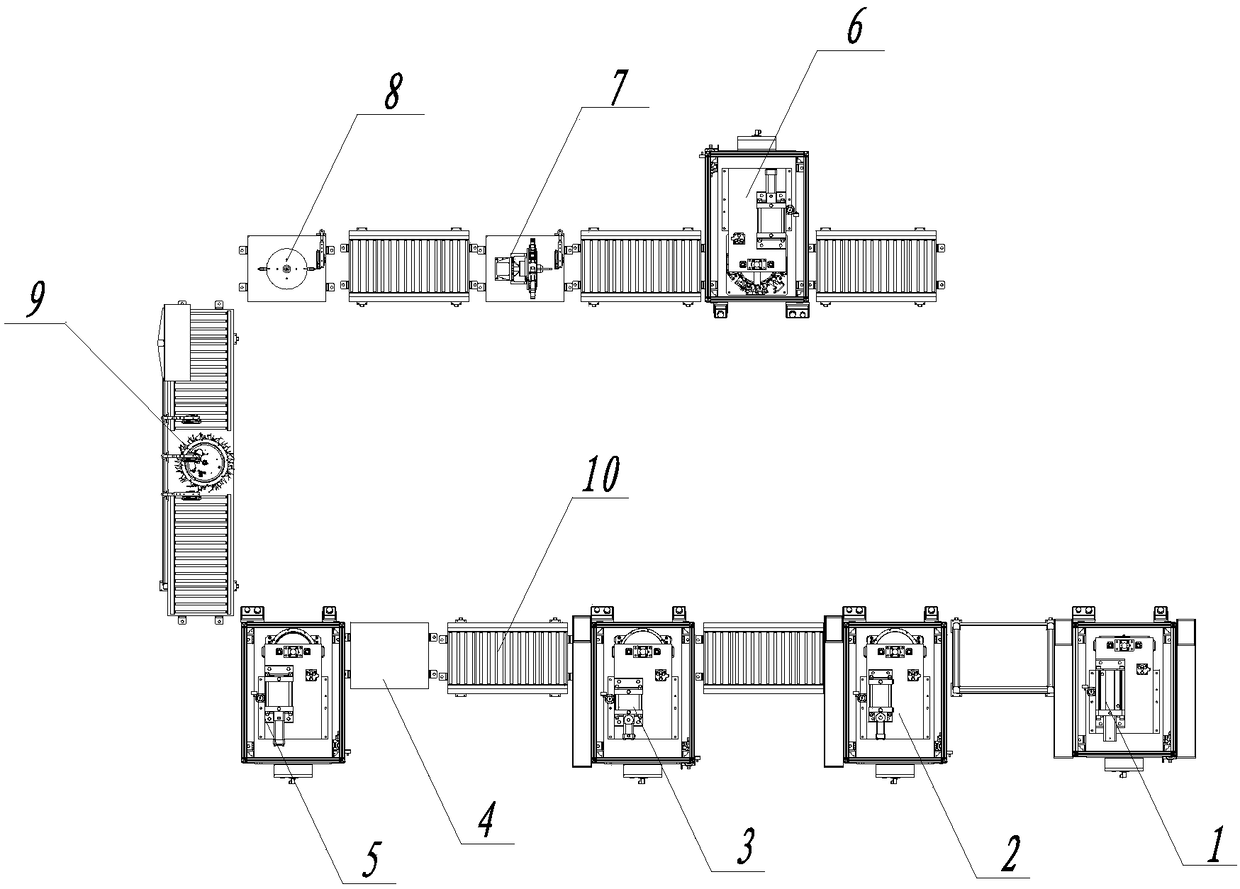

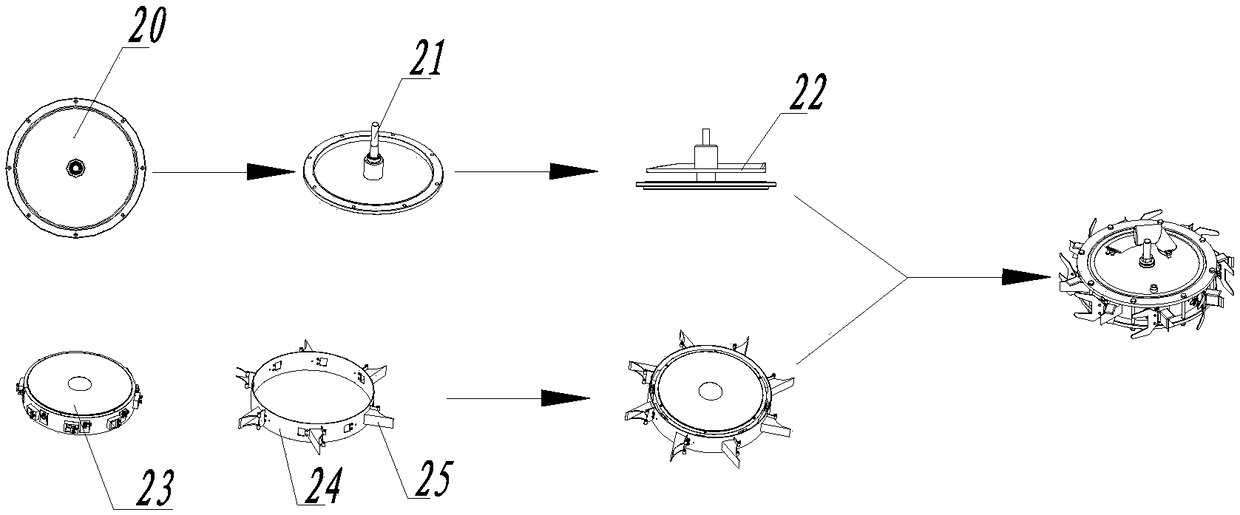

[0031] See figure 1 , the present invention comprises the first assembly production line that main shaft 21, bearing, internal fixed disk 22 and main disk 20 are assembled together, the second assembly production line that will get seed disk 23, belt disk 24 and duckbill 25 is assembled together, and will The semi-finished products obtained by the first production line and the second production line are assembled into the finished product assembly station 9 of the final product.

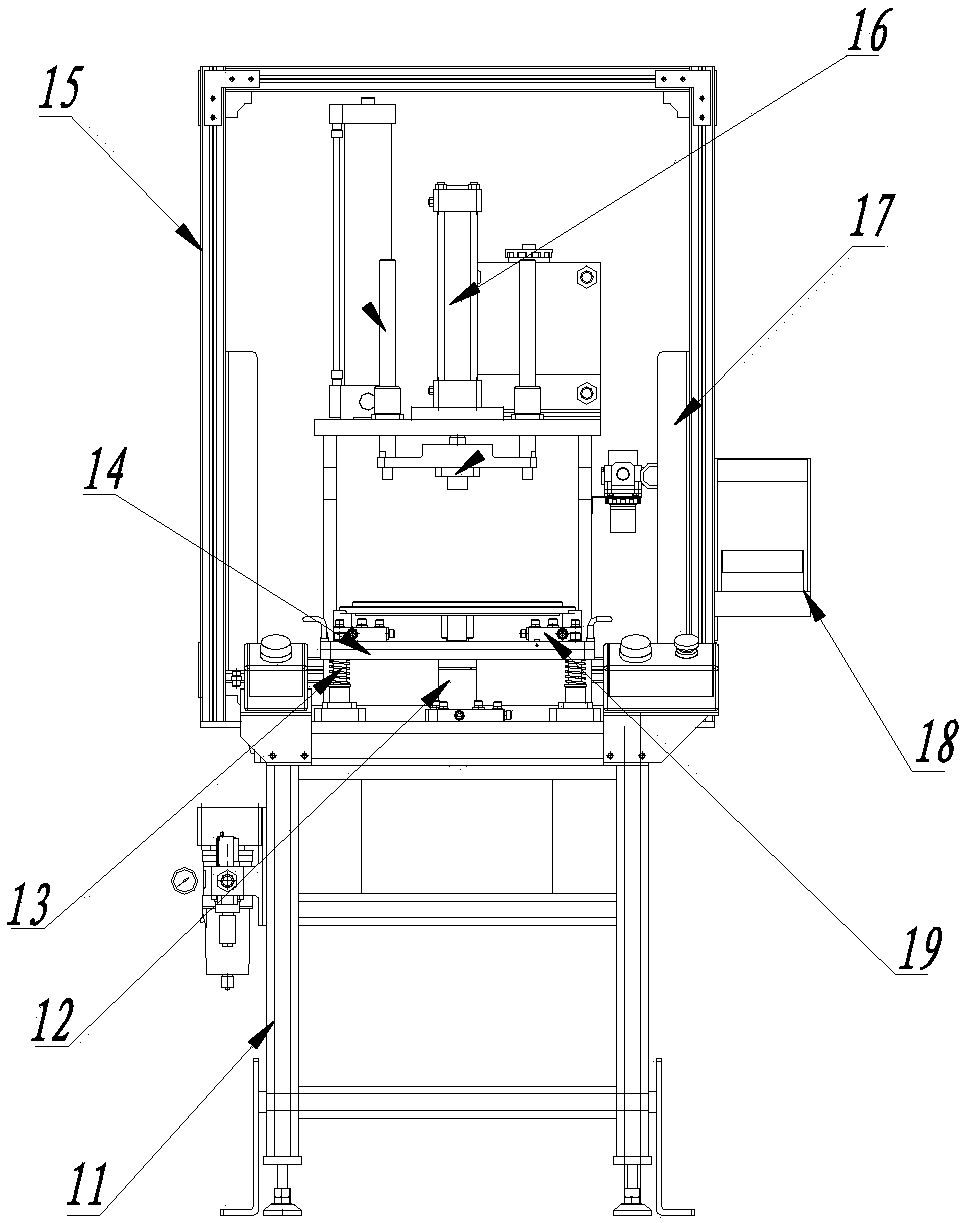

[0032] The first assembly line includes a bearing press-in spindle station 1, a bearing press-in main disk station 2, a spindle press-in main disk station 3, an inner fixed disk pre-installation station 4, and an inner fixed disk pressed into the main disk station. Disk station 5, the fixed disk is pressed into the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com