Aerated building block transfer system

A technology of aerated blocks and transfer racks, applied in railway braking systems, buildings, building structures, etc., can solve problems affecting the stability of aerated blocks, high cost, and low transportation efficiency, and achieve improved stability and transshipment efficiency, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

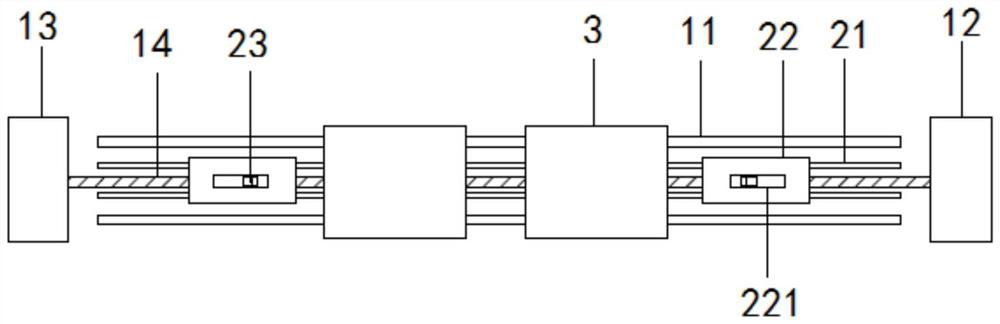

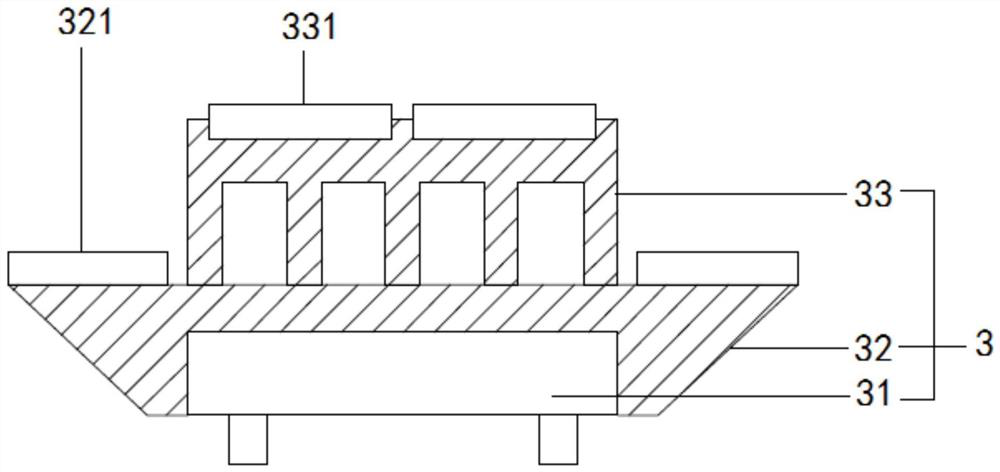

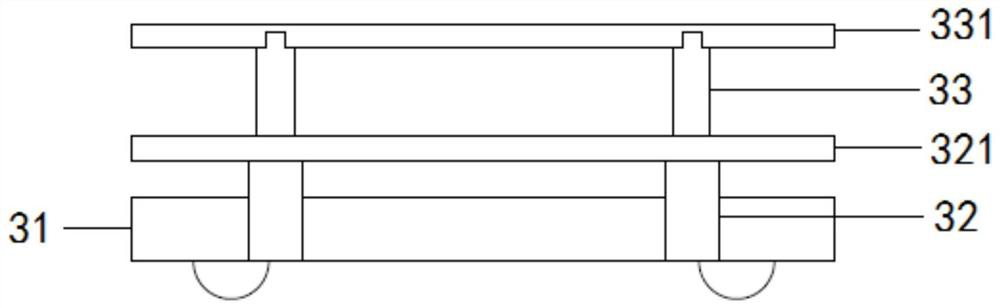

[0025] see Figure 1 to Figure 4 , the present embodiment provides an aerated block transfer system, first of all, a traction device, a brake device and a quick-load transfer frame 3 are provided, the traction device includes a first guide rail 11 and a driving assembly, and the first guide rail 11 is laid on the ground, The opposite ends of the first guide rail 11 are respectively the starting point of transfer and the end point of transfer. The fast loading transfer frame 3 is slidably installed on the first guide rail 11. The fast loading transfer frame 3 moves towards the starting point or end point of transfer under the drive of the drive assembly, and brakes The device includes a second guide rail 21, a brake pad mounting base 22 and a brake pad body 23. The second guide rail 21 is located in the middle of the first guide rail 11. The brake pad mounting base 22 is fixedly connected to the quick-load transfer frame 3 and slides on the second guide rail 21. , The brake pad...

Embodiment 2

[0033] see Figure 1 to Figure 4 , the figure shows an aerated block transfer system provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: in Embodiment 1 The fast-loading transfer frame is a boat-shaped transfer frame. In order to maintain stability during transportation, the same amount of aerated blocks needs to be placed on both ends of the ship-shaped transfer frame, so that the boat-shaped transfer frame can maintain balance on both sides.

Embodiment 3

[0035] see Figure 1 to Figure 4 , the figure shows an aerated block transfer system provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: In order to further improve the fast For the stability of the transfer rack during transportation, an anti-tipping bar is welded on opposite ends of the quick-load transfer rack. The bottom end of the tipping bar will touch the ground, so as to prevent the quick-load transfer frame from tipping over at a greater angle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com