Air outlet and method for the production thereof

An exhaust port and air outlet technology, which is applied to the exhaust port and its manufacturing field, can solve the problems of restricting the ventilation effect and the impossibility of the lining of the exhaust port orifice plate, and achieves the effect of rapid installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

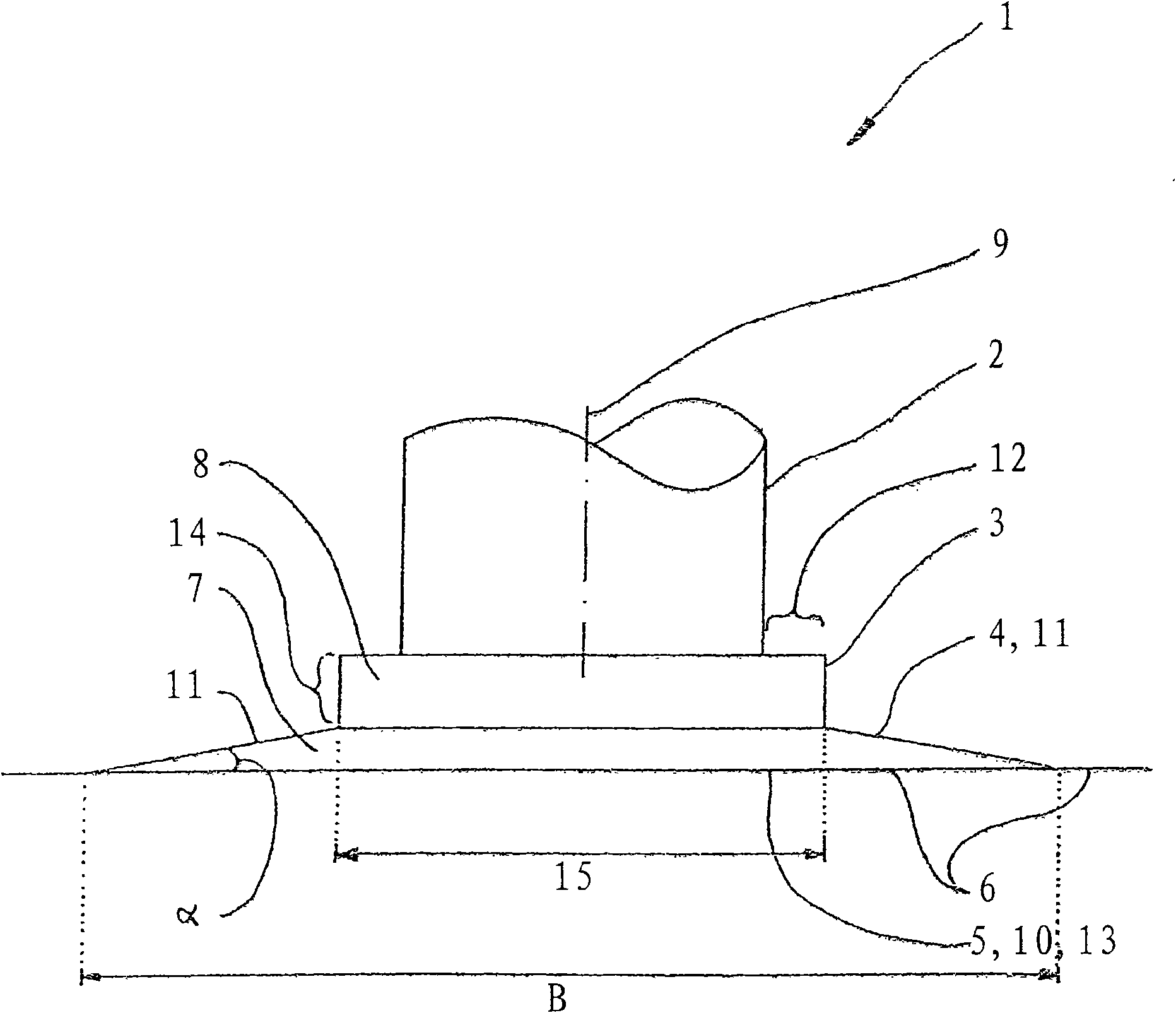

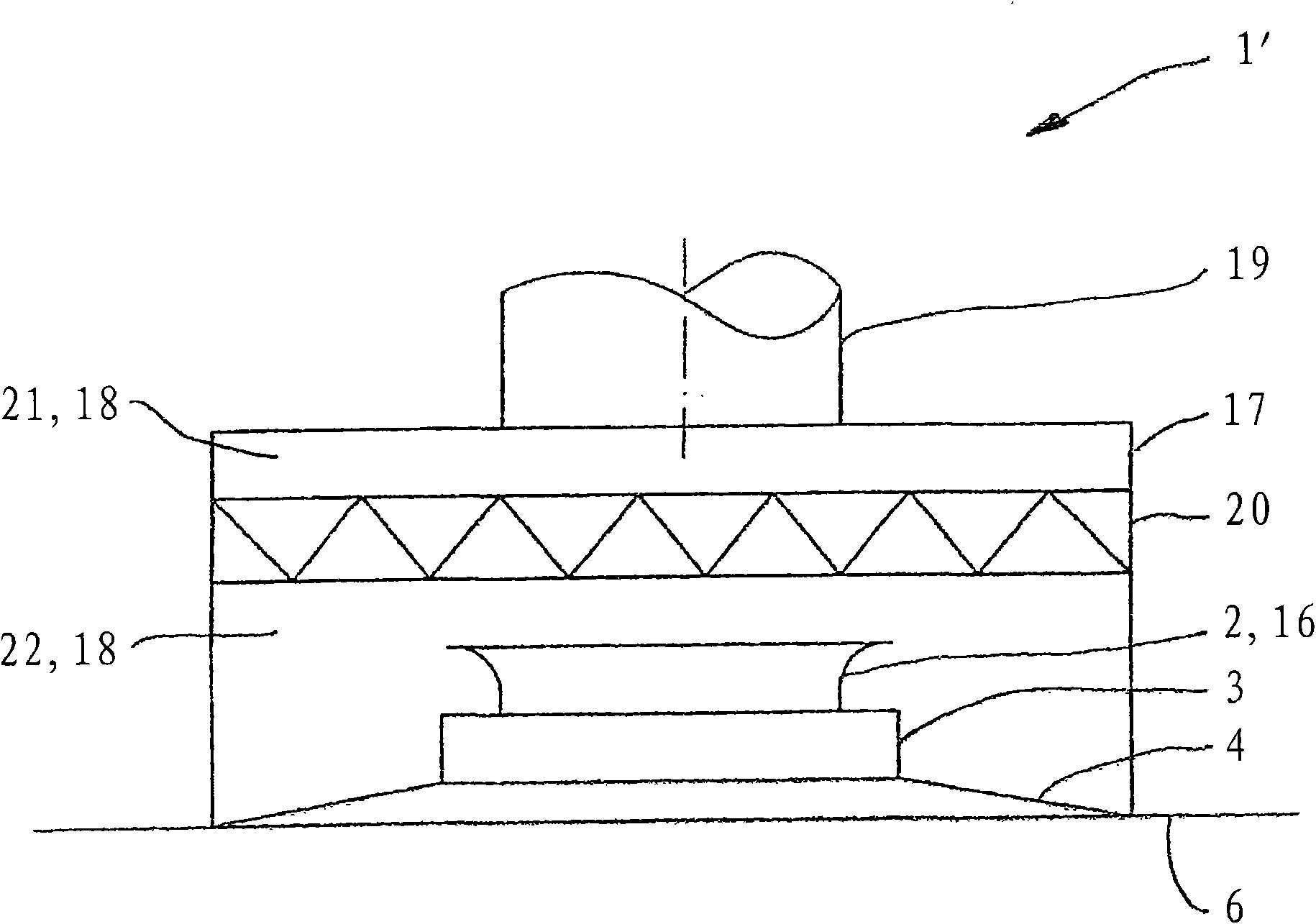

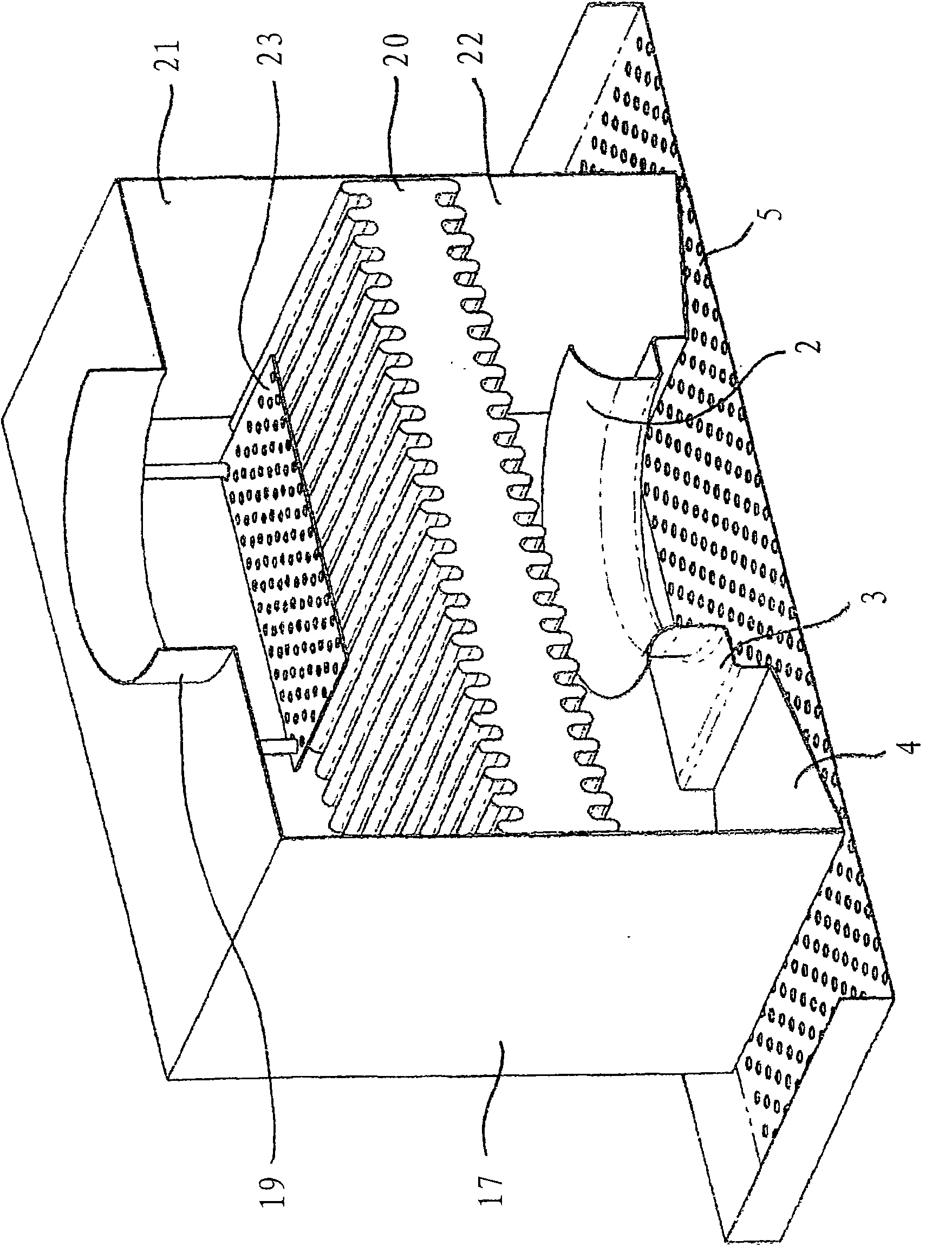

[0028] exist figure 1 Essential components of the invention can be seen in the shown vertical section through a first embodiment of an air outlet 1 according to the invention, in particular a ceiling air outlet. The exhaust port 1 has a connection 2 for at least indirect connection to an air supply system (not shown). Firstly a transition piece is connected to the connection piece 2 and then the housing 4 is attached, which in turn is attached to a ceiling panel 6 designed as a perforated plate 5 . The air distribution chamber 7 is delimited by the ceiling panel 6 and the housing 4 , and the interior cavity 8 of the transition section 3 can likewise be regarded as an air distribution chamber. The center line 9 of the socket 2 runs perpendicularly to the ceiling panel 6 .

[0029] Initially, that is to say before the start of assembly, only the connecting piece 2, the transition piece 3 and the housing 4 form a unit which is not yet functional and has a completely free air ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com