Method for operating a transmission device with a plurality of friction-locking and positive-locking shifting elements

一种换挡元件、摩擦锁合的技术,应用在运输和包装、带有齿的元件、多传动比传动装置等方向,能够解决降低驾驶舒适性的换挡噪音、剧烈刹车等问题,达到高舒适性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

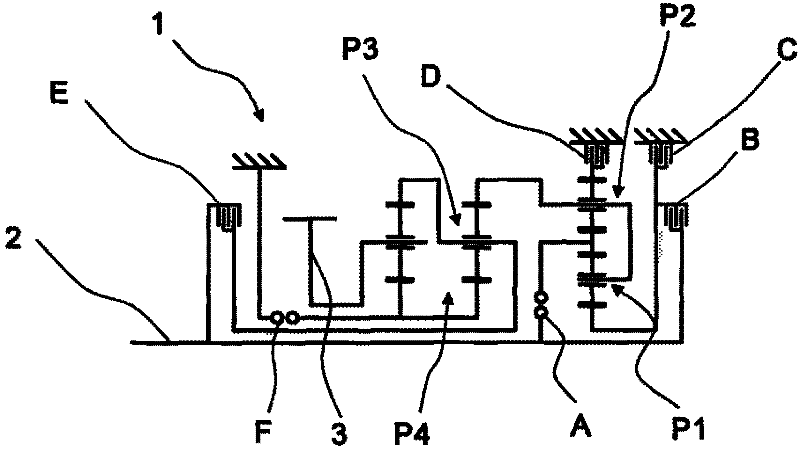

[0026] figure 1 A schematic representation of the gears of the transmission arrangement 1 or of a multi-stage transmission is shown, which is known in principle from the unpublished German patent application DE 102008000429.4 of the same applicant. The transmission device 1 comprises a drive shaft 2 , which is connected to the output end of the vehicle when installed in the vehicle, and a driven shaft 3 , which is operatively connected to the drive machine.

[0027] Furthermore, the transmission device 1 comprises four planetary gearsets P1 to P4, wherein the first and second planetary gearsets P1, P2, which are preferably designed as negative planetary gearsets, form a shiftable front gearset, while the third and The fourth planetary gear set P3, P4 constitutes the main gear set. The transmission device 1 additionally comprises six shifting elements A to F, wherein the shifting elements B, D and E are designed as brakes and the shifting elements A, C and F are designed as sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com