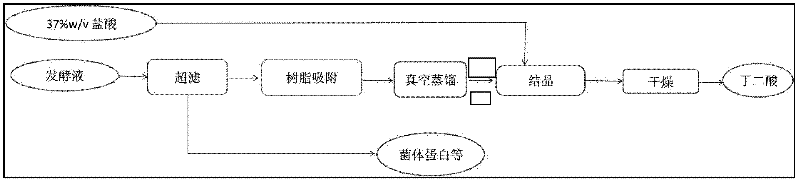

Method for separating and purifying succinic acid from fermentation broth

A technology for separating and purifying and fermenting liquid, which is applied in the technical field of separating and purifying succinic acid from fermentation liquid, can solve the problems of poor economy, difficult coupling of fermentation processes, unreasonable unit operation design, etc., and achieves the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Using glucose as the carbon source, Actinobacillus succinate BE-1 is the succinic acid fermentation broth of the production strain, wherein the concentration of succinic acid is 45g / L, the concentration of formic acid is 8g / L, the concentration of acetic acid is 10g / L, and the concentration of lactic acid The concentration is 14g / L, the amount of residual sugar is less, and the pH of the fermentation broth is 6.8.

[0066] The fermented liquid is subjected to ultrafiltration operation. The ultrafiltration operation adopts hollow fiber membrane equipment. The membrane material is PES membrane. The membrane separation capacity is 10kDa. After filtering, the removal rate of protein was 91%. At this time, the concentration of succinic acid was 43g / L. D301 type resin was used to decolorize succinic acid. The decolorization temperature was 40°C. The concentration is 40g / L. The fermented liquid after clarification and decolorization is vacuum distilled and concentrated, the co...

Embodiment 2

[0069] Using glucose as the carbon source, Actinobacillus succinate BE-1 is the succinic acid fermentation liquid of the production strain, wherein the concentration of succinic acid is 52g / L, the concentration of formic acid is 9g / L, the concentration of acetic acid is 7g / L, and the concentration of lactic acid The concentration is 17g / L, the amount of residual sugar is less, and the pH of the fermentation broth is 6.6.

[0070] The fermentation broth is processed according to two schemes, scheme 1: fermentation broth—centrifugation—decolorization—vacuum distillation concentration—crystallization; scheme 2: fermentation broth—ultrafiltration—decolorization—vacuum distillation concentration—crystallization;

[0071] Option 1: Centrifuge the fermentation broth obtained above at a speed of 6000r / min for 30 minutes, collect the supernatant after centrifugation, and use D301 resin to decolorize succinic acid at a temperature of 40°C. After decolorization, the fermentation broth is ...

Embodiment 3

[0075] Using glucose as the carbon source, Actinobacillus succinate BE-1 is the succinic acid fermentation liquid of the production strain, wherein the concentration of succinic acid is 62g / L, the concentration of formic acid is 10g / L, the concentration of acetic acid is 6g / L, and the concentration of lactic acid The concentration is 18g / L, no residual sugar, and the pH of the fermentation broth is 6.8.

[0076] Two schemes are adopted for the clarification of the fermentation broth. Scheme 1: Microfiltration followed by ultrafiltration; Scheme 2: The fermentation broth is clarified directly by ultrafiltration.

[0077] Option 1: Microfiltration-ultrafiltration operation is performed on the fermentation broth at the same time for comparison. The microfiltration operation uses a hollow fiber microfiltration membrane, the pore size of the microfiltration membrane is 0.1 μm, the membrane material is PE membrane, and the cross-flow operation is adopted. method, the operating tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com