Disc type sludge dryer

A sludge drying, disc type technology, used in dewatering/drying/concentrating sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

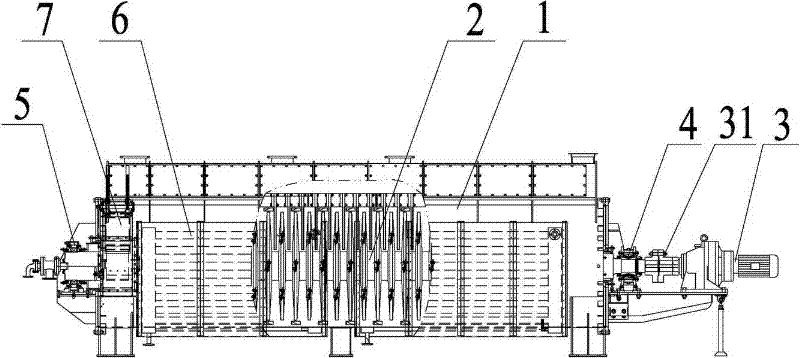

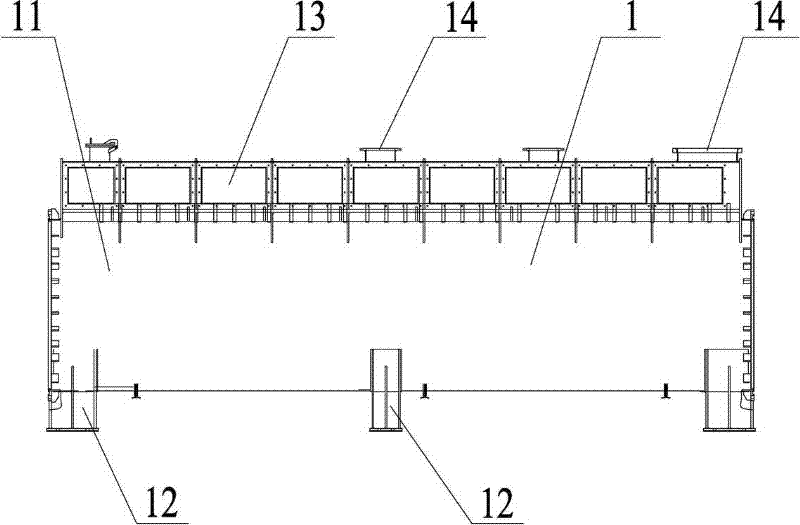

[0034] Please refer to the attached figure 1 To attach Figure 10 As shown, the present invention is a disc type sludge dryer, which consists of a housing 1, a spindle system 2, a gear motor 3, a transmission end bearing device 4, a steam end bearing device 5, a heating and heat preservation device 6 and a discharge device 7 and other systems.

[0035] Wherein, the main shaft system 2 and the heating and heat preservation device 6 are accommodated in the housing 1, the main shaft system 2 is used to stir and heat the sludge to make it preliminarily dry, and the heating and heat preservation device 6 is used for heat preservation of the preliminarily dried sludge, Let it dry out further. The transmission end bearing device 4 and the steam end bearing device 5 are respectively installed at both ends of the main shaft system 2. The transmission end bearing device 4 is used to transmit power to the main shaft system 2 to make the main shaft system 2 rotate. The steam end bearin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com