Electromagnetic band gap structure for optimizing power distribution network of PCB (printed circuit board) and construction method thereof

A technology of power distribution network and electromagnetic bandgap structure, which is applied in the direction of electrical components, printed circuits, printed circuit manufacturing, etc., can solve the problems of high relative frequency band bandwidth and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below in conjunction with the accompanying drawings.

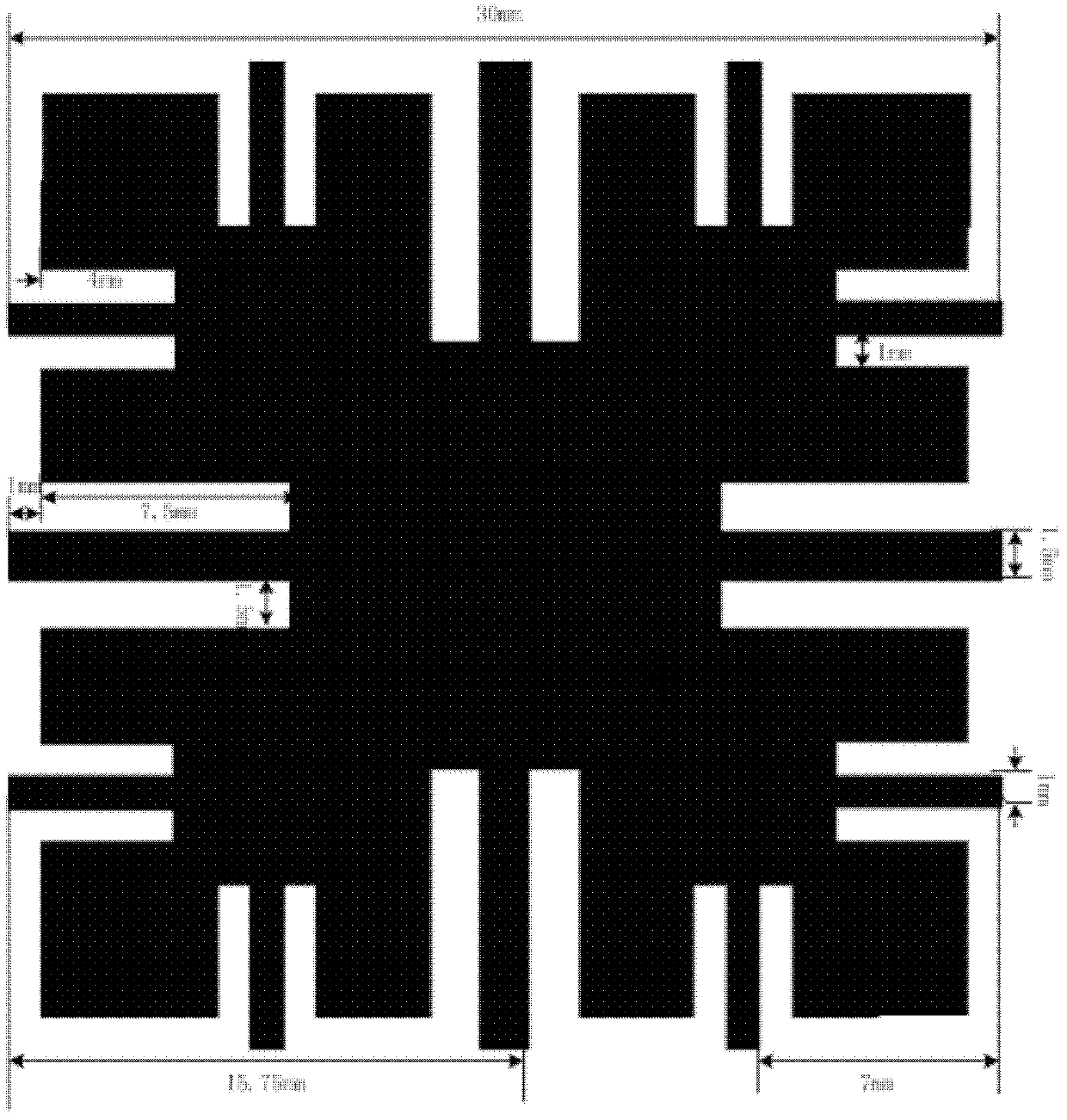

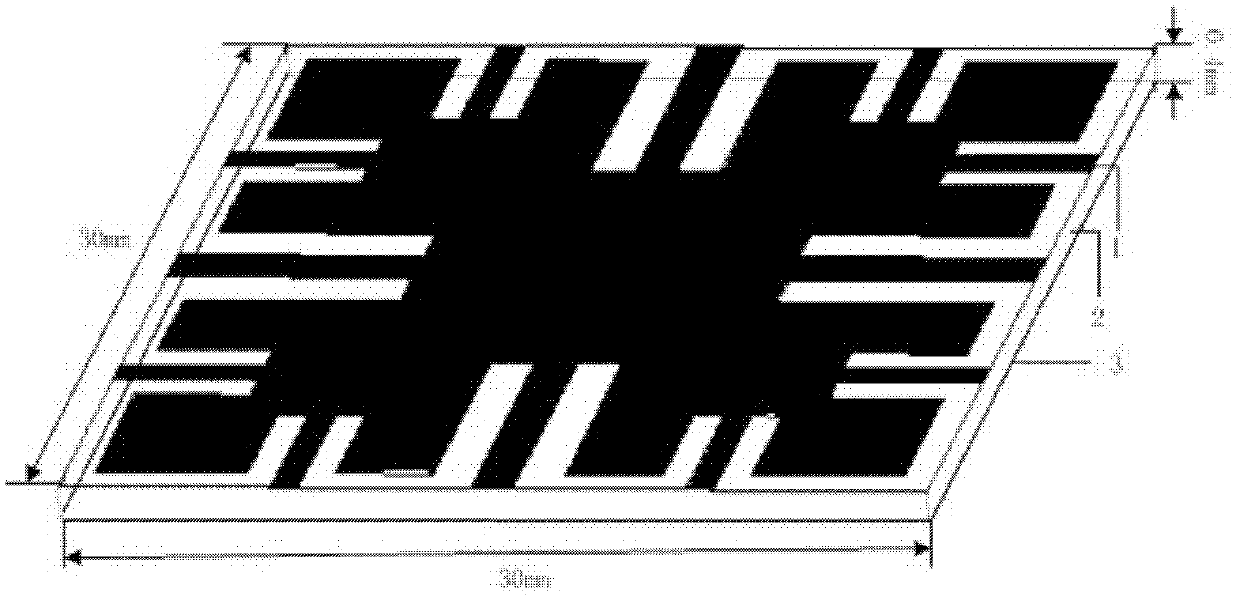

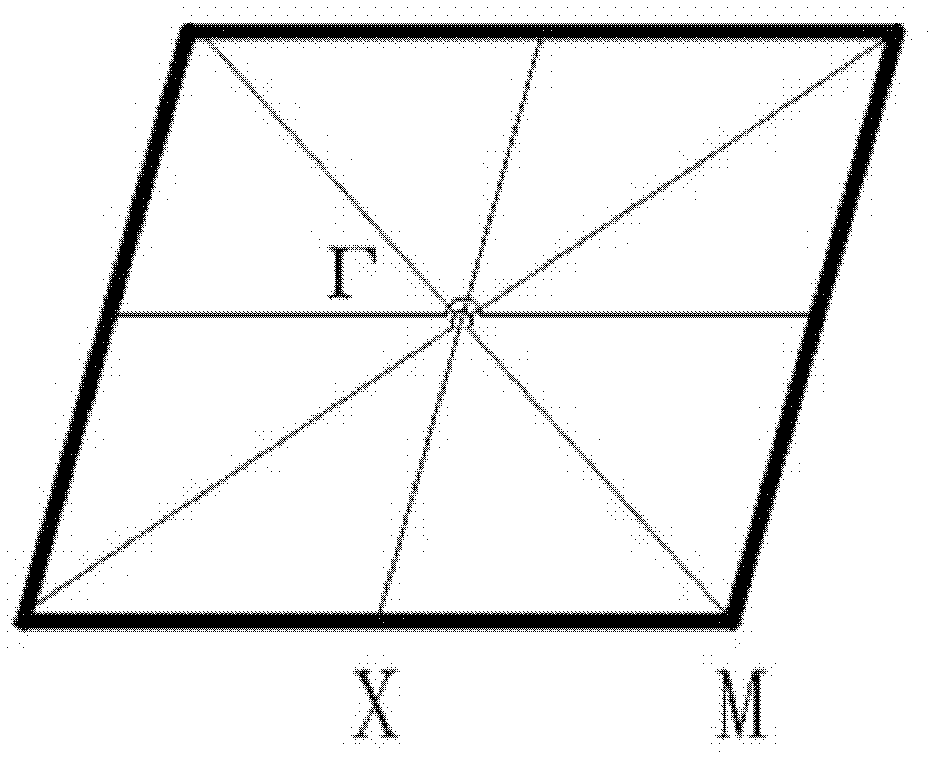

[0056] The invention designs a compound coplanar EBG structure with low lower limit cut-off frequency and high bandwidth for high-speed circuit system, which realizes suppression of high-frequency band noise in high-speed signal circuit PDN. On the basis of the traditional classic planar EBG structure, the structure increases the path of the narrow bridge-shaped connecting metal branches, makes full use of the redundant space of the structural unit, increases the spatial distribution rate of the narrow bridge-shaped connecting metal branches in the structural unit, and realizes the new EBG structure. The characteristics of low cut-off frequency and high bandwidth provide conditions for realizing the miniaturization of EBG structure. The composite coplanar EBG structure in the present invention is a 3×3 EBG structure formed by periodically extending a periodic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com