Communication cable for ducts

A technology for communication cables and pipelines, which is applied in the direction of cables with twisted pairs/quadruple strands, etc. It can solve the problems of pipeline installation that cannot adapt to large angles, installation and laying and inconvenient use, and the weight of communication cables. , to meet the requirements of large-angle installation and laying, light weight, good weather resistance and hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

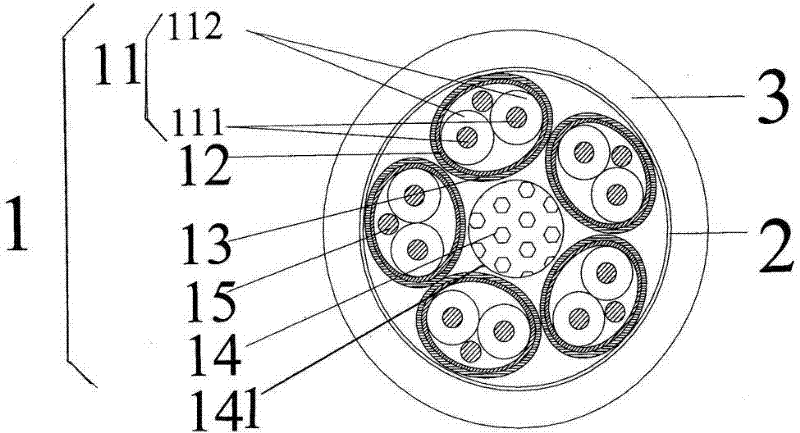

[0021] please see figure 1 , figure 1 It is essentially a schematic cross-sectional view of the present invention, which shows the cable core 1, the first wrapping layer 2 wrapped outside the cable core 1 and the sheath layer 3 outside the first wrapping layer 2, wherein: the cable core 1 Including five data line pairs 11, second and third wrapping layers 12, 13, central reinforcement 14 and ground wire 15, each data line pair 11 includes a pair of conductors 111 and a coating layer covering each conductor 111 112. The conductor 111 is made of tinned stranded copper wire with a single wire diameter of 0.12mm, and the coating layer 112 is a fluoroplastic coating layer, that is, the material is fluoroplastic as the coating layer 112. The data line pairs 11 are twisted to each other, and the adjacent data line pairs 11 are twisted to each other around the central reinforcement 14. When each data line pair 11 is twisted by itself, each data line pair 11 is wrapped around eac...

Embodiment 2

[0024] The picture is omitted, the number of data line pairs 11 is changed to six pairs; the diameter of the monofilament of the conductor 111 is changed to 0.5mm; the thickness of the aluminum foil is changed to 0.035mm; the polyester wrapping tape that will serve as the third wrapping layer 13 Change the thickness of the ground wire 15 to 0.030㎜; change the diameter of the tinned stranded copper wire constituting the ground wire 15 to 0.2㎜; change the thickness of the polyester wrapping tape 141 wrapped around the central reinforcement 14 to 0.03㎜; The thickness of the first wrapping layer 2 (polyester wrapping tape) is changed to 0.03 mm. All the other are the same as the description to embodiment 1.

Embodiment 3

[0026] The picture is omitted, the number of data line pairs 11 is changed to four pairs; the diameter of the monofilament of the conductor 111 is changed to 0.1mm; the thickness of the aluminum foil is changed to 0.04mm; the polyester wrapping tape that will serve as the third wrapping layer 13 change the thickness of the tinned stranded copper wire that constitutes the ground wire 15 to 0.1mm; change the thickness of the polyester wrapping tape 141 wrapped around the central reinforcement 14 to 0.025mm; The thickness of the first wrapping layer 2 (polyester wrapping tape) is changed to 0.02mm. All the other are the same as the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com