Truss combined beam and upper and layer connected light steel structure and construction method thereof

A light steel structure and composite beam technology, applied in truss-type structures, long-strip structural members for load-bearing, truss beams, etc., can solve the problems of low production efficiency, poor integrity of components, weak connections, etc. The effect of poor connection strength, high manufacturing precision and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

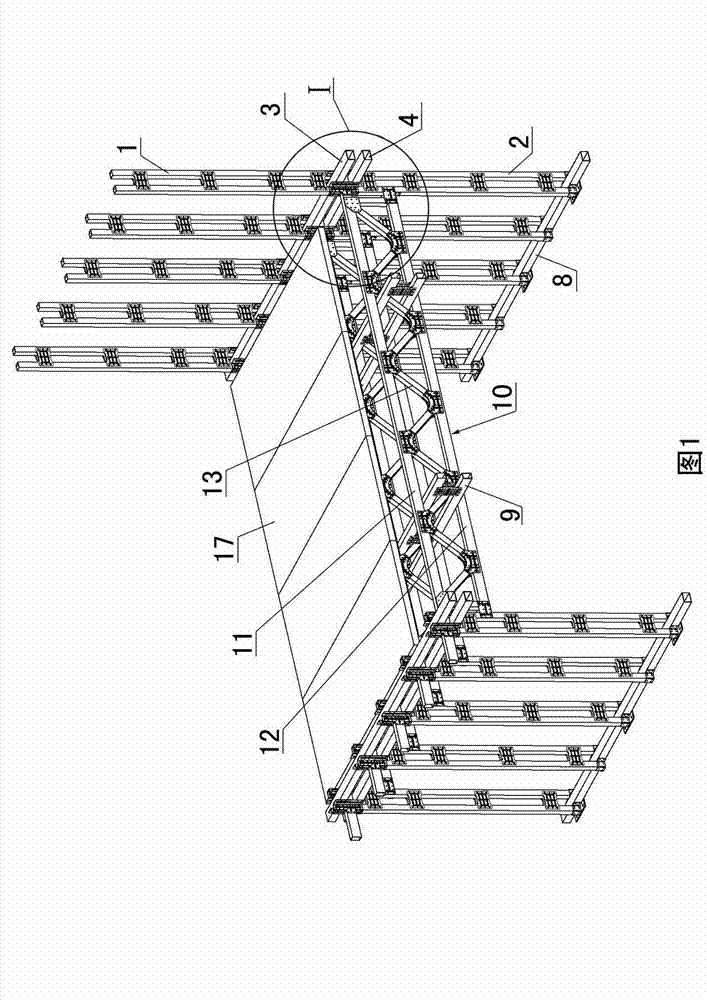

[0056] Examples see figure 1 , figure 2 As shown, this kind of light steel structure with truss composite beams connected to the upper and lower floors includes the upper wall sheet columns 1 distributed at intervals, the lower wall sheet columns 2 distributed at intervals, and the lower wall sheet columns connected between the upper wall sheet columns. The upper wall sheet column lower connecting pipe 3, the lower wall sheet column upper connecting pipe 4 connected between the top of the lower wall sheet column, and the upper wall sheet column and the lower wall sheet connected by the upper and lower layer connectors The truss composite beam between the columns, the upper wall sheet column 1 and the lower wall sheet column 2 both include two vertical rods and a vertical rod connector connected between the two vertical rods, and the truss composite beam includes Floor beams 10 distributed at intervals in the horizontal direction and connecting beams 9 connected between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com