Epoxy asphalt cement mortar, preparation method, and application of epoxy asphalt cement mortar in ballastless tracks

A technology of epoxy asphalt and cement mortar, applied in the direction of track, road, ballast layer, etc., to achieve the effect of wide service temperature range, strong chemical corrosion resistance and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

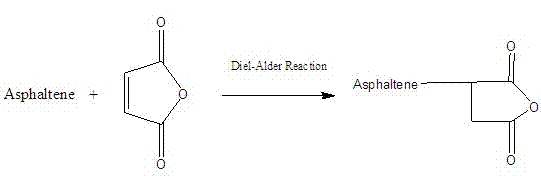

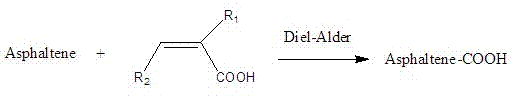

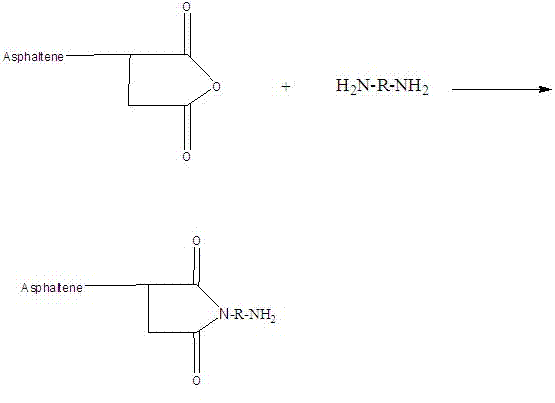

Method used

Image

Examples

Embodiment 1

[0042] Prepare each raw material according to the ratio, weigh 1460 kilograms of dry powder, and epoxy asphalt emulsion A and B components are 231.6 kilograms and 38.6 kilograms respectively (wherein A:B=1:6, the solid content of A and B components are both 60%.), 170 kg of water, 5.5 kg of water reducer, and 0.5 kg of defoamer. The cement in the dry powder material is Conch brand P.II.525 portland cement produced in Tongling. The fineness mode of the sand in the dry powder material is 1.4-1.7. The defoamer is a water-based silicone defoamer from Henan Daochun Co., Ltd. The water reducer is a polycarboxylate water reducer produced by Fuzhou Chuangxian New Material Co., Ltd.

[0043]Prepare according to the following process:

[0044] a. Prepare various raw materials according to the ratio.

[0045] b. Add components A and B of epoxy asphalt emulsion, add water and water reducer at the same time, and stir at a low speed (30r / min) for 1 minute.

[0046] c. Add defoamer, stir...

Embodiment 2

[0056] Prepare each raw material according to the ratio, weigh 1455 kilograms of dry powder, and epoxy asphalt emulsion A and B components are 214.2 kilograms and 35.7 kilograms respectively (wherein A:B=1:6, the solid content of A and B components are both 60%.), 175 kg of water, 6.0 kg of water reducer, and 0.6 kg of defoamer. The cement in the dry powder material is Conch brand P.II.525 portland cement produced in Tongling. The fineness mode of the sand in the dry powder material is 1.4-1.7. The defoamer is a water-based silicone defoamer from Henan Daochun Co., Ltd. The water reducer is a polycarboxylate water reducer produced by Tianjin Yongyang Co., Ltd.

[0057] Prepare according to the following process:

[0058] a. Prepare various raw materials according to the ratio.

[0059] b. Add components A and B of epoxy asphalt emulsion, add water and water reducer at the same time, and stir at a low speed (30r / min) for 1 minute.

[0060] c. Add defoamer, stir at low speed...

Embodiment 3

[0070] Prepare each raw material according to the ratio, weigh 1460 kilograms of dry powder, and epoxy asphalt emulsion A and B components are 227.5 kilograms and 32.5 kilograms respectively (wherein A:B=1:7, the solid content of A and B components are both 60%.), 168 kg of water, 5.0 kg of water reducer, and 0.5 kg of defoamer. The cement in the dry powder material is Conch brand P.II.525 portland cement produced in Tongling. The fineness mode of the sand in the dry powder material is 1.4-1.7. The defoamer is a water-based silicone defoamer from Henan Daochun Co., Ltd. The water reducer is a polycarboxylate water reducer produced by Fuzhou Chuangxian New Material Co., Ltd.

[0071] Prepare according to the following process:

[0072] a. Prepare various raw materials according to the ratio.

[0073] b. Add components A and B of epoxy asphalt emulsion, add water and water reducer at the same time, and stir at a low speed (30r / min) for 1 minute.

[0074] c. Add defoamer, sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com