Method for connecting 2XXX and 7XXX heterogeneous aluminum alloy by laser filler wire

A dissimilar aluminum alloy and laser wire filling technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as easy formation of hydrogen pores, instability of welding process, and difference in hydrogen solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

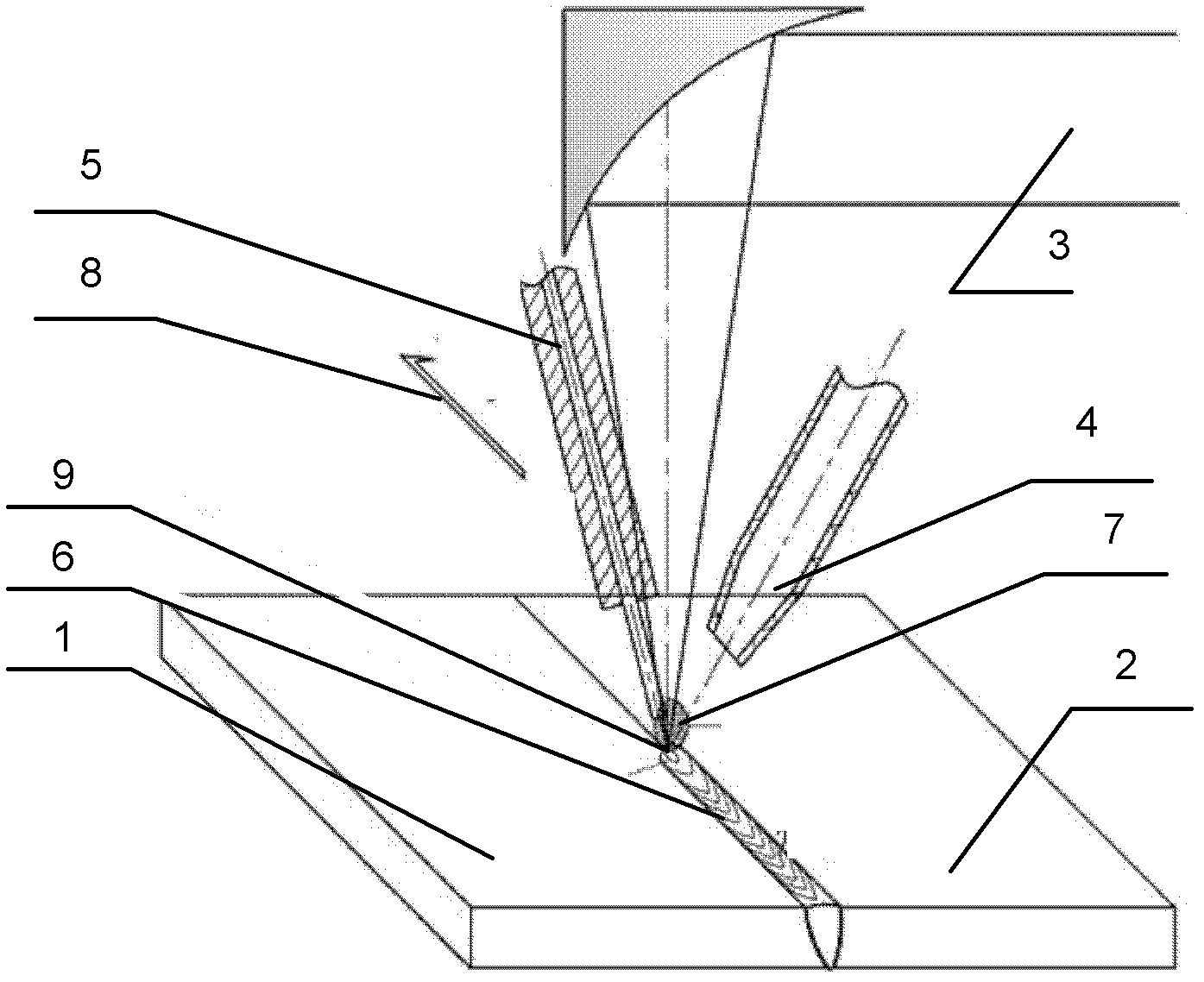

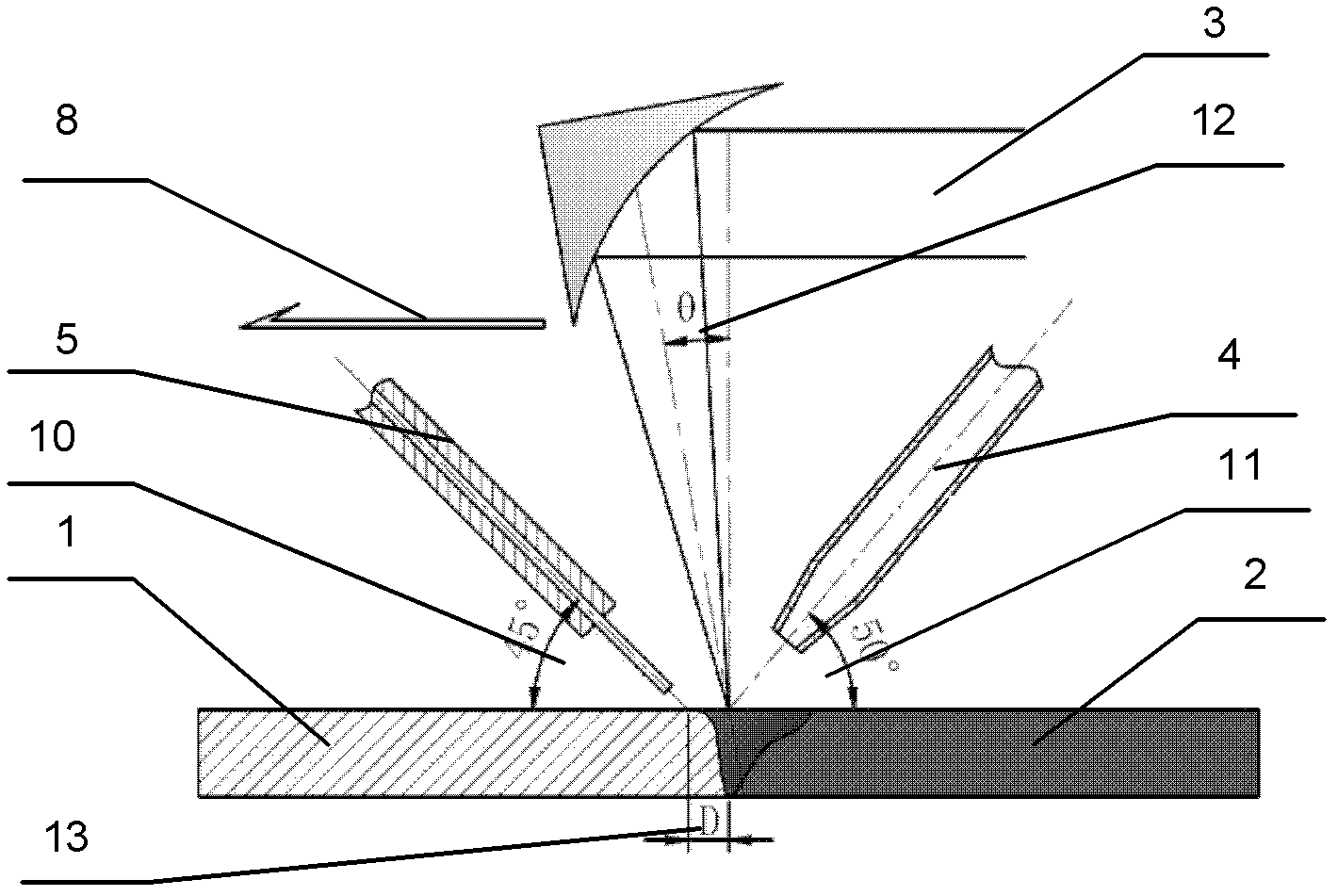

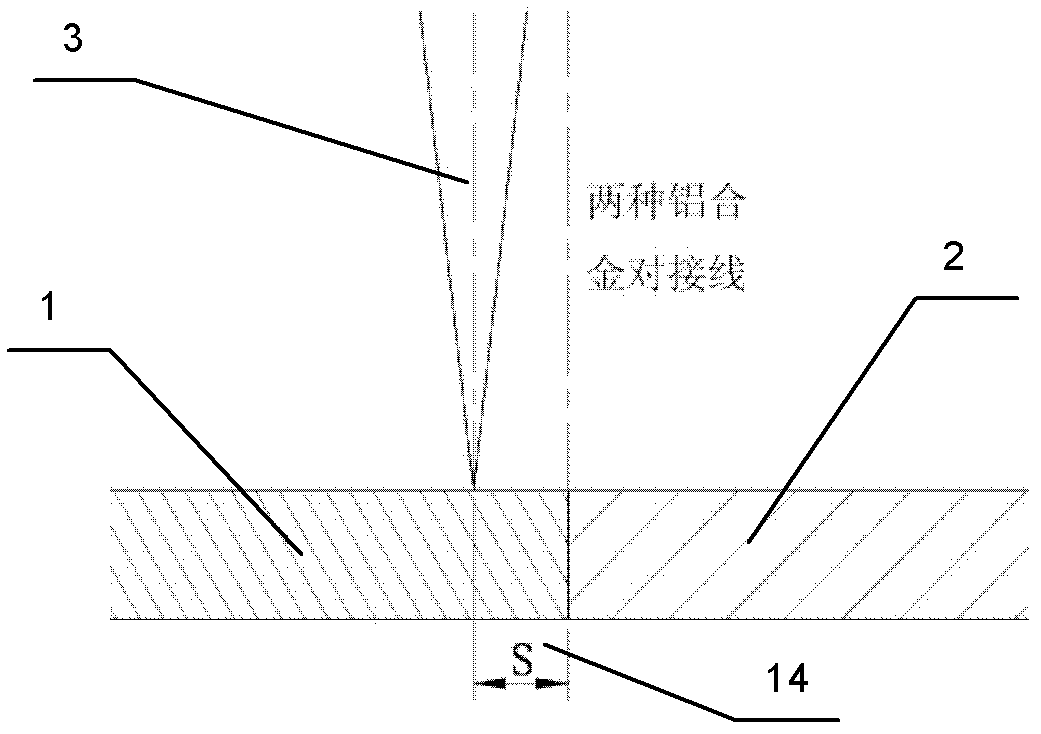

[0031] Method 1:

[0032] When using AlCu welding wire with a diameter of 1.2mm (the wire grade is 2319) as the filler material to weld and connect 2024 and 7075 dissimilar aluminum alloys, first clean the surfaces of the materials to be welded 2024 and 7075, and assemble them into figure 1 The butt joint of the laser beam 3, the wire feeding nozzle 5 and the shielding gas nozzle 4 are fixed in the same plane, and the wire feeding nozzle 5 and the shielding gas nozzle 4 are respectively located on both sides of the laser beam 3 (the wire feeding angle and the shielding gas angle are respectively 45° and 55°), the laser beam 3 is incident on the surface of the material to be welded (1 and 2) at an incident angle of 12 (10°), the distance between the filaments 13 is 0, and the focus of the laser beam is located on the 2XXX aluminum alloy plate 1 , The laser offset is 14 at 0.5mm, the parameters of laser welding are laser power 3500W, welding speed 4m / min, wire feeding speed 3.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com