Automatic welding method for circumferential welding seam of round pipe

A circumferential welding and automatic welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of difficulty in meeting welding requirements, difficult operation of round pipe fittings, insufficient automation, etc., and achieve the effect of good mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

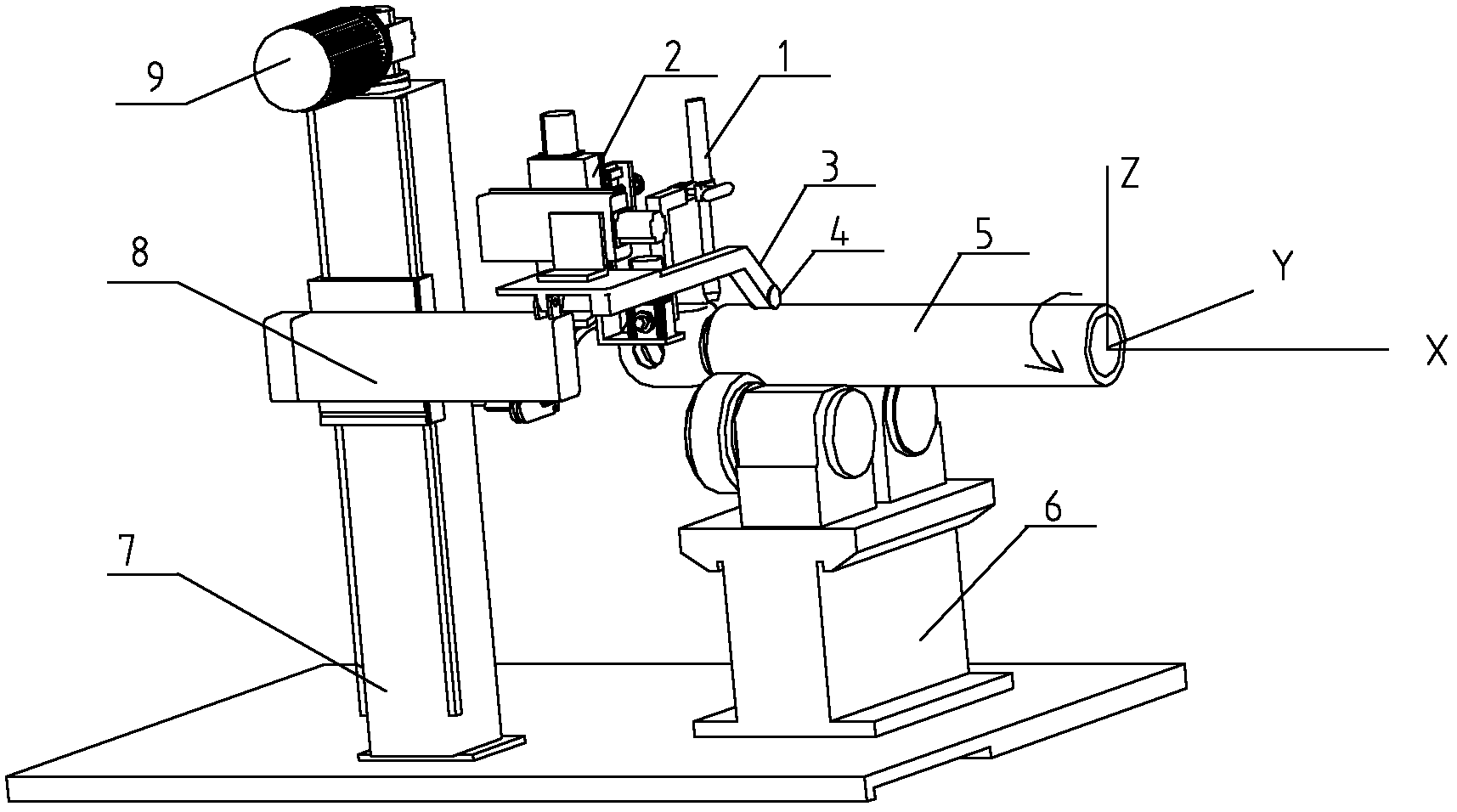

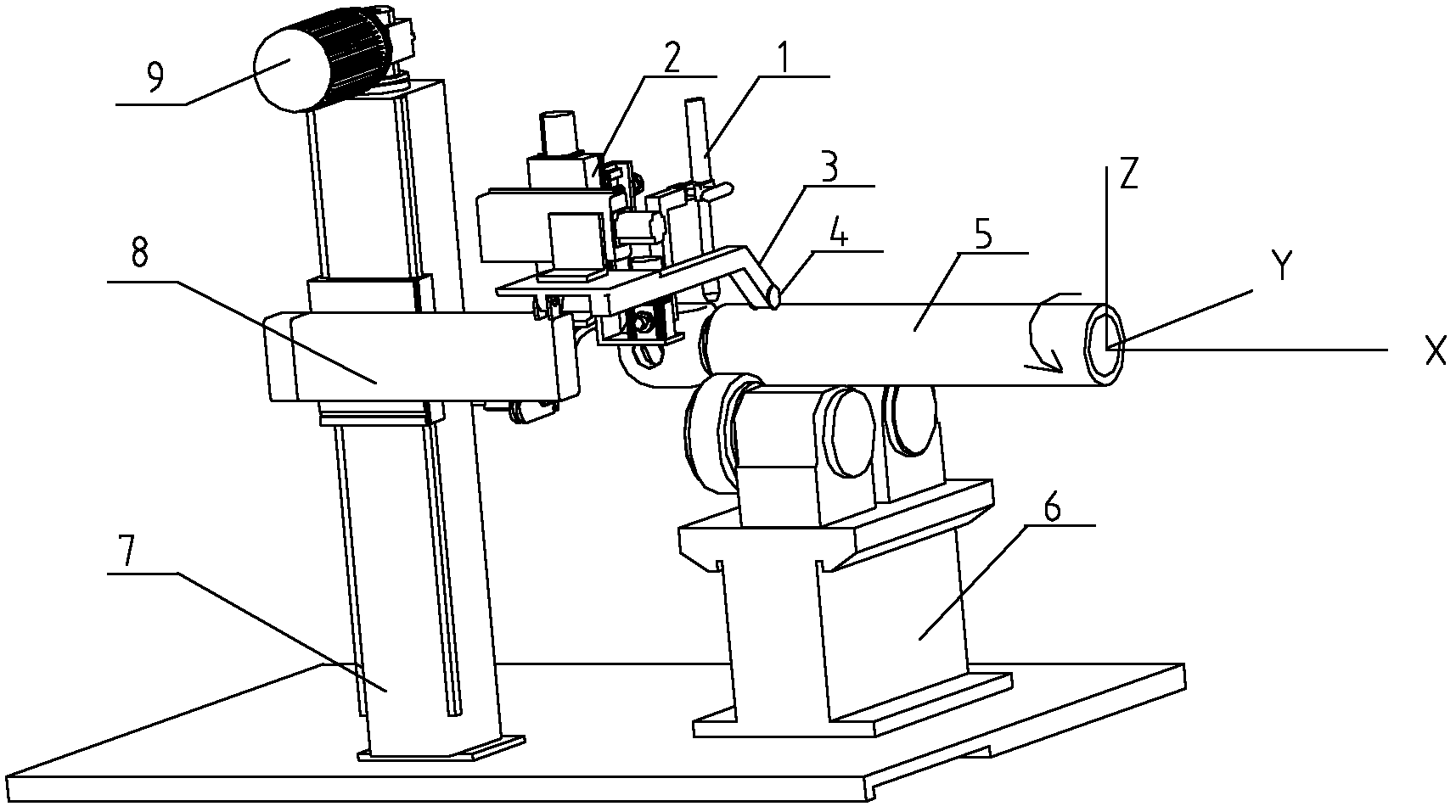

[0032] In the present invention, unless otherwise stated, the orientation words used such as "axial" and "radial" are usually for round pipes. figure 1 In the coordinates representing the three-dimensional direction, the "X" axis indicates the axial direction of the round pipe, and the "Y" and "Z" axes both represent the radial direction of the round pipe. The term "welding position" in this article refers to the position of the welding torch head during welding, and "welding angle" refers to the inclination angle of the welding torch from the vertical direction (or horizontal direction) at the center of the welding point, that is, in swing welding The inclinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com