Method and die for continuous production of one group of asymmetric hinge blades

An asymmetric hinge technology, applied in the field of mechanical processing, can solve the problems of continuous production of asymmetric hinge blades, complex mold structure, and inability to achieve differentiated production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

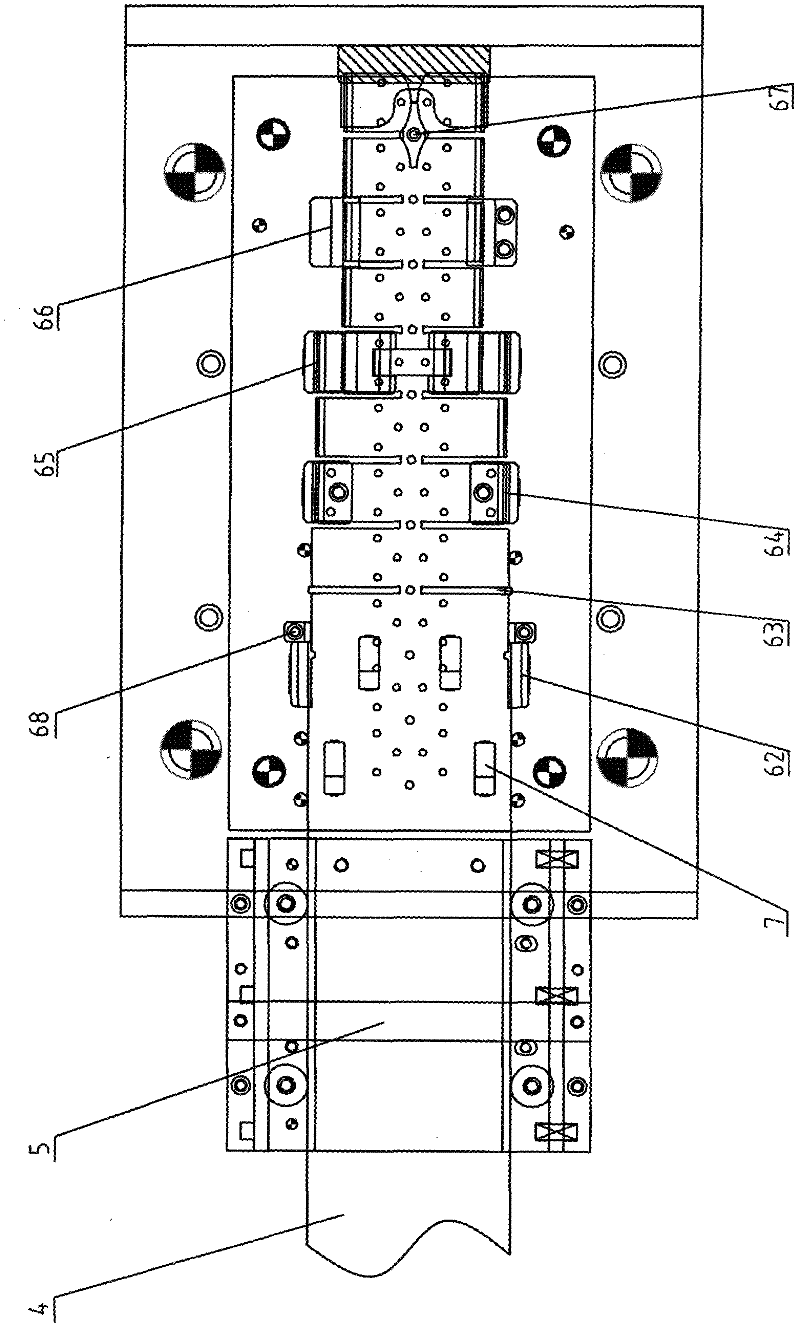

[0035] Example 1, such as figure 1 As shown, the present invention discloses a method for continuously producing a group of asymmetric hinge blades. The method uses a continuous mold to process long strips at the same time. The specific steps are as follows: The surface of the continuously conveyed long strip is punched with round holes. In this embodiment, 7 round holes are punched each time; Specific process such as figure 1 As shown; then the strip after the trimmed burr is initially positioned to determine the step distance, and then the square hole is cut. In this embodiment, two symmetrical square holes are cut on the strip; then use two Different fillet forming punches perform fillet forming on both sides of the strip after cutting the square hole. The specific process is as follows: figure 1 As shown; then use the bending forming punch to bend the two sides of the rounded strip at 90°, the specific process is as follows figure 1 shown; and then use the rolling formi...

Embodiment 2

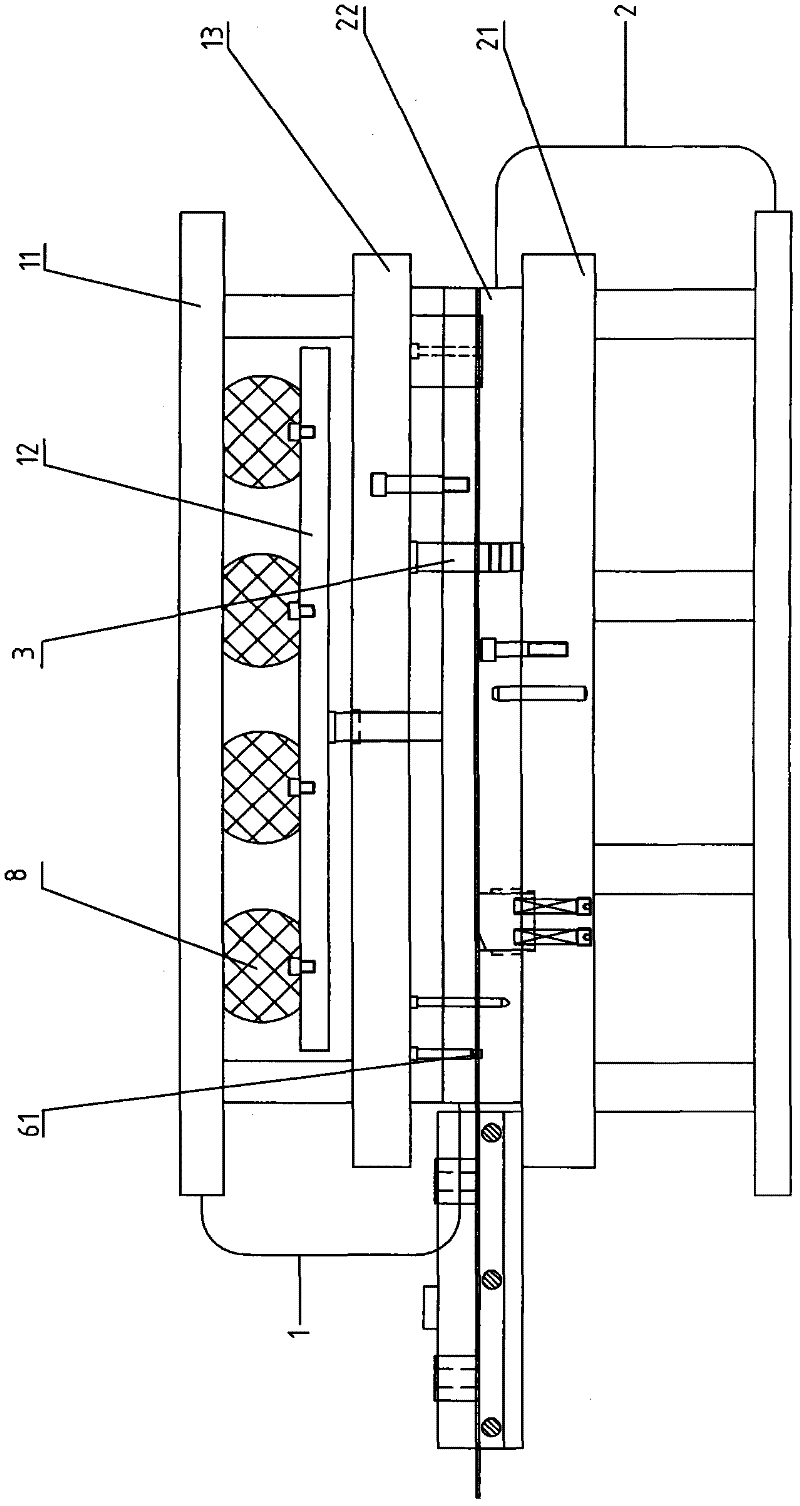

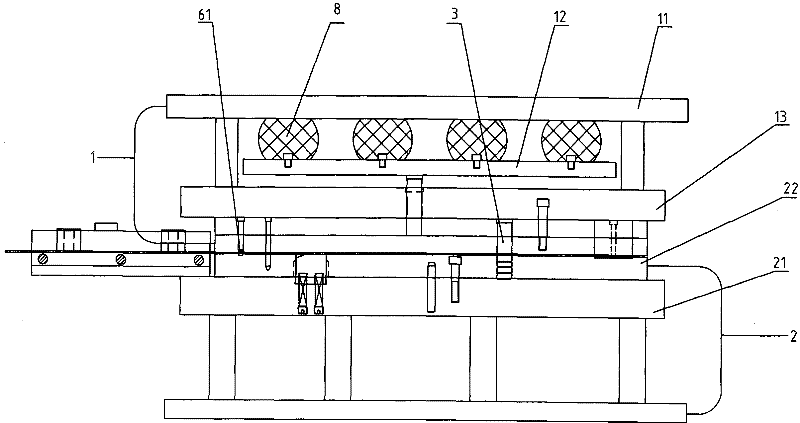

[0037] Example 2, such as figure 1 with figure 2 As shown, the present invention discloses a mold for continuously producing a group of asymmetric hinge blades, including an upper mold 1 and a lower mold 2, and the upper mold 1 includes an upper mold base 11, an upper backing plate 12 and an upper template 13 , the lower mold 2 includes a lower mold base 21 and a lower template 22, the upper mold 1 and the lower mold 2 are connected by an inner guide post 3, and a mold cavity is formed between the upper and lower molds, and the strip material 4 enters through the feeding rack 5 In the mold cavity, on the upper mold 1, a round hole punch 61, a symmetrical edge trimming punch 62, a symmetrical square hole cutting punch 63, and asymmetric rounded corner forming punches 64, Bending and forming punches 65 symmetrical on both sides, round forming blocks 66 symmetrical on both sides, and cutting punches 67 arranged in the center.

[0038] On the upper die 1, a symmetrical position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com