Charcoal electrode specially used in smelting of ferroalloy and preparation method thereof

A technology of ferroalloy and carbon electrodes, which is applied in the field of special carbon electrodes for ferroalloy smelting and its preparation, can solve the problems of threatening the lives of operators, national property safety, electrode paste consumes a lot of energy, and affects people's health, so as to improve the efficiency of electric furnaces, The effect of shortening the smelting time and saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

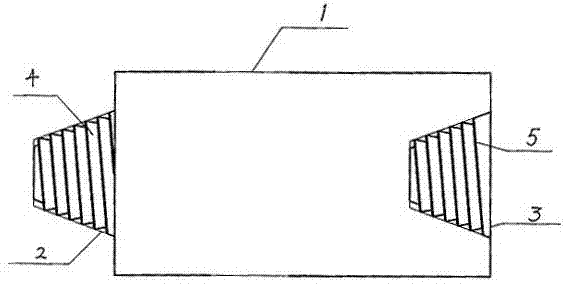

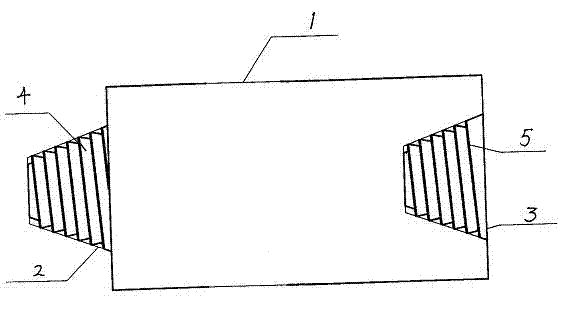

Image

Examples

Embodiment 1

[0034] The first step: preparation

[0035] A. Crushing and screening the calcined solid raw material electric calcined coal;

[0036] B. A part of petroleum coke and graphite is crushed and sieved, and a part is pulverized with a ball mill;

[0037] C, start kneading in the kneading pot according to the proportioning of 0.2 parts by weight of carbon black and 0.2 parts by weight of adhesive, take out the paste after the kneading is completed, and press the paste into flakes and blocks on the molding machine, and then Break the flake and block paste, and finally grind the paste into small particles, which is the carbon black secondary material;

[0038] Step 2: Ingredients and Dry Blending

[0039] According to claim 1, the electronic batching system weighs 12 parts by weight of crushed graphite with a particle diameter of 4 mm or less, 12 parts by weight of crushed graphite with a particle diameter greater than 4 mm and less than or equal to 8 mm, and 8 parts by weight with...

Embodiment 2

[0049] The first step: preparation

[0050] A. Crushing and screening the calcined solid raw material electric calcined coal;

[0051] B. A part of petroleum coke and graphite is crushed and sieved, and a part is pulverized with a ball mill;

[0052] C, start kneading in the kneading pot according to the proportioning of 0.5 parts by weight of carbon black and 0.4 parts by weight of adhesive, take out the paste after the kneading is completed, and press the paste into flakes and blocks on the molding machine, and then Break the flake and block paste, and finally grind the paste into small particles, which is the carbon black secondary material;

[0053] Step 2: Ingredients and Dry Blending

[0054] According to claim 1, the electronic batching system weighs 16 parts by weight of crushed graphite with a particle diameter of 4 mm or less, 16 parts by weight of crushed graphite with a particle diameter greater than 4 mm and less than or equal to 8 mm, and 11 parts by weight wit...

Embodiment 3

[0064] The first step: preparation

[0065] A. Crushing and screening the calcined solid raw material electric calcined coal;

[0066] B. A part of petroleum coke and graphite is crushed and sieved, and a part is pulverized with a ball mill;

[0067] C, start kneading in the kneading pot by the proportioning of 0.8 parts by weight of carbon black and 0.6 parts by weight of adhesive, take out the paste after the kneading is completed, and press the paste into flakes and blocks on a molding machine, and then Break the flake and block paste, and finally grind the paste into small particles, which is the carbon black secondary material;

[0068] Step 2: Ingredients and Dry Blending

[0069] According to claim 1, the electronic batching system weighs 20 parts by weight of crushed graphite with a particle size of 4 mm or less, 20 parts by weight of crushed graphite with a particle size greater than 4 mm and less than or equal to 8 mm, and 14 parts by weight with a particle size gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com