Combustor and spray drying tower using same

A burner and flame retardant technology, which is applied to burners, gas fuel burners, combustion methods, etc., can solve the problems of unenvironmental use of steam energy and the inability to increase the inlet air temperature, and achieves improved drying capacity, increased temperature, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

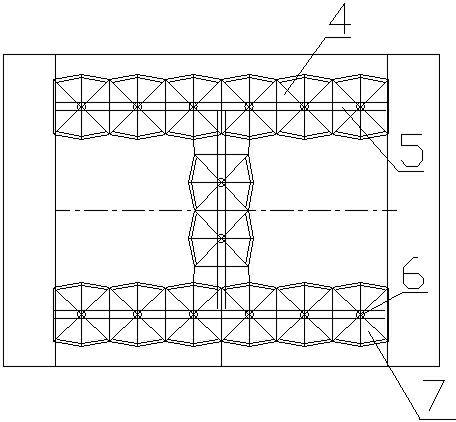

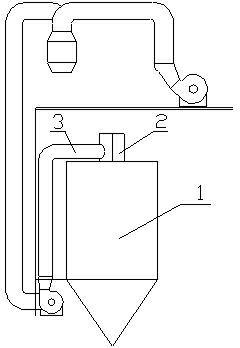

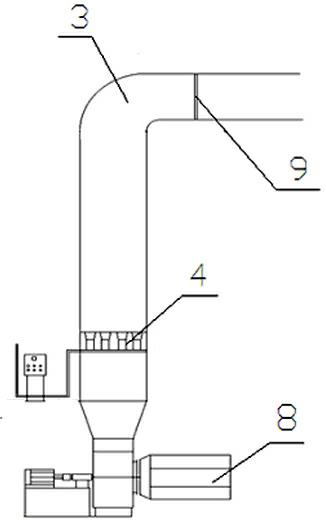

[0019] Such as Figures 1 to 3 As shown, a spray drying tower includes a drying tower body 1 and a feed pipe 2 and an air inlet pipe 3 whose outlet is arranged on the top of the drying tower body 1, and a burner 4 is arranged in the middle of the air inlet pipe 3; The gas inlet pipe 5 of the device 4 is I-shaped, and its upper surface is provided with a plurality of injection nozzles 6, and the outer edge of the I-shaped gas inlet pipe is provided with a protective cover 7, and the protective cover 7 is upward and downward from the outer edge of the I-shaped gas inlet pipe. Expand outward. The gas passed through the intake pipe is clean and environment-friendly natural gas. The air inlet pipe 3 also includes an air inlet filter 8 arranged in front of the air inlet end of the burner 4 and a flame arrester 9 arranged behind the burner 4 . Flame retardant 9 can be made up of two protective nets by front and back two net sheets, prevents that combustible or combustion particle e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com