Method for preparing metal carboxylate super-hydrophobic coating on surface of metal

A metal carboxylate, super-hydrophobic coating technology, applied in the direction of metal material coating process, can solve the problems of lengthy process, unfavorable materials for large-scale production, etc., and achieve the effect of broadening the scope of application, low price, and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0037] (1) Surface treatment of pure copper plate. Sand with 600 grit metallographic sandpaper to remove the surface oxide layer, then rinse with distilled water and dry.

[0038] (2) Dip the pure copper plate in 99% ethyl acetate solution and ultrasonically clean it for 10 minutes to remove surface oil, then wash it with distilled water and dry it.

[0039] (3) with 1.7gCuCl 2 2H 2 Prepare a 0.1 mol / L solution of O with 100 mL of 99.7% ethanol solution. Apply the prepared solution to the treated pure copper plate.

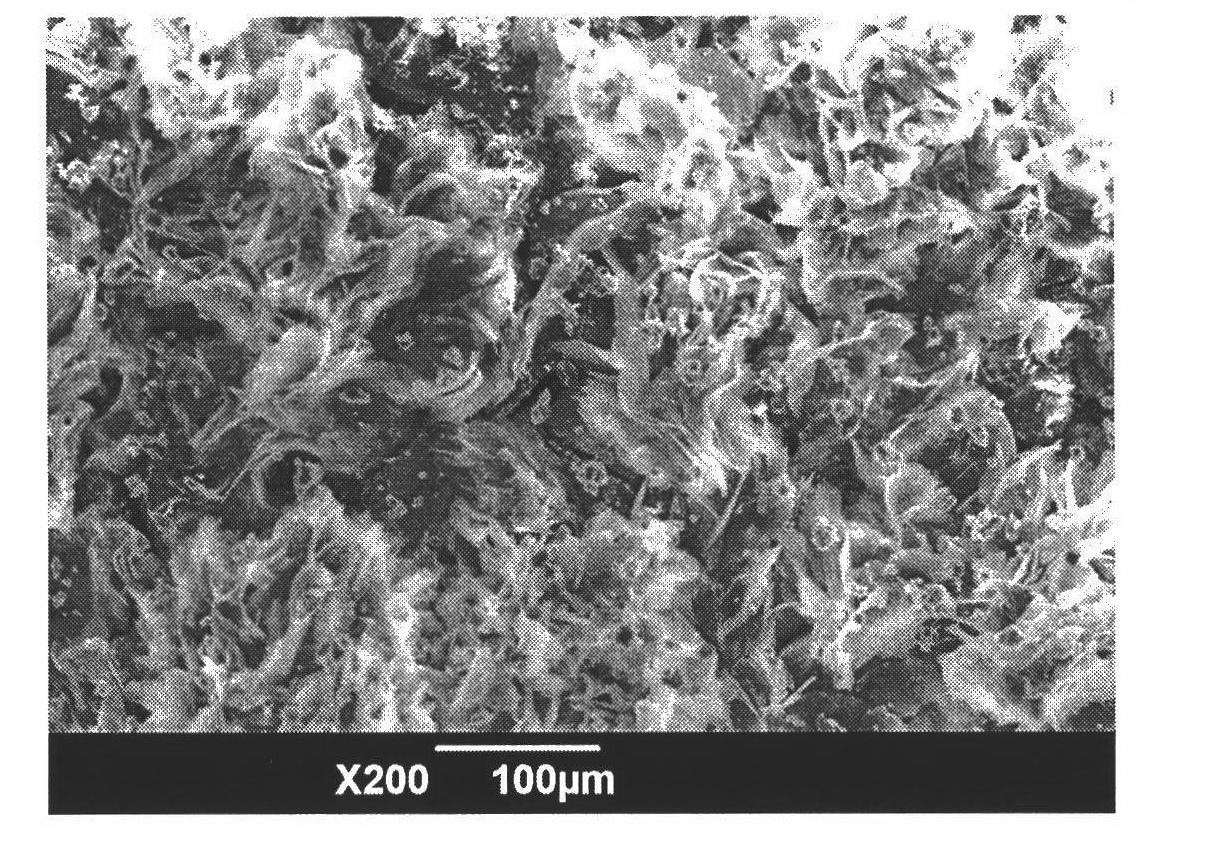

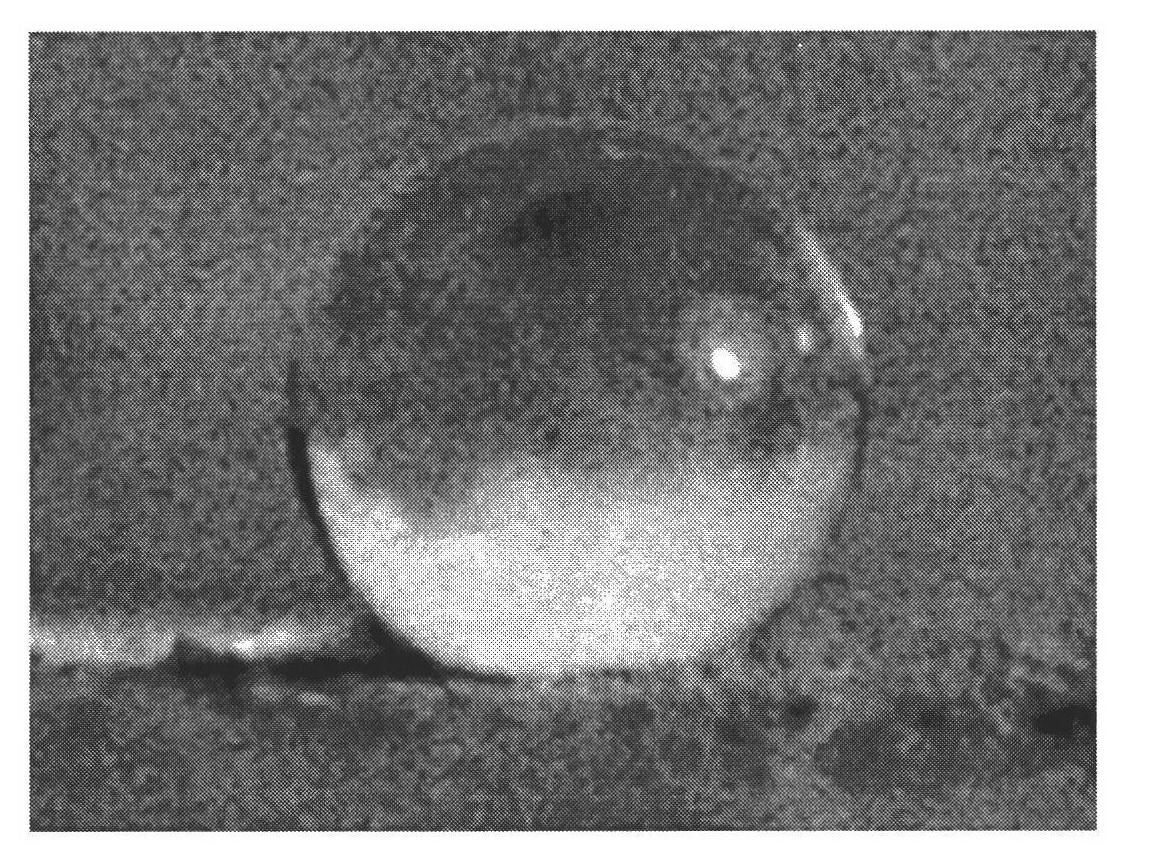

[0040] (4) Immerse the pure copper plate coated with the solution in water for several minutes, take it out and dry it at room temperature for 2 hours to obtain a superhydrophobic coating. The contact angle is about 170° and the rolling angle is less than 2°.

example 2

[0042] (1) Surface treatment of the iron plate. Sand with 240-grit metallographic sandpaper to remove the surface oxide layer, then rinse with distilled water and dry.

[0043] (2) Dip the metal plate in 99% ethyl acetate solution and ultrasonically clean it for 20 minutes to remove surface oil, then wash it with distilled water and dry it.

[0044] (3) with 5.5g FeCl 3 ·6H 2 Prepare a 0.2 mol / L solution of O and 100 mL of ethanol with a mass fraction of 99.7%. Apply the prepared solution to the treated iron plate.

[0045] (4) Immerse the iron plate coated with the solution in water for several minutes, take it out and dry it at room temperature for 2 hours to obtain a super-hydrophobic coating. The contact angle is about 165° and the rolling angle is less than 2°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com