Municipal sludge drying method

A technology for municipal sludge and sludge drying, which is applied in the direction of dewatering/drying/concentrating sludge treatment to reduce pollution, eliminate secondary pollution, and eliminate bacteria and viruses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

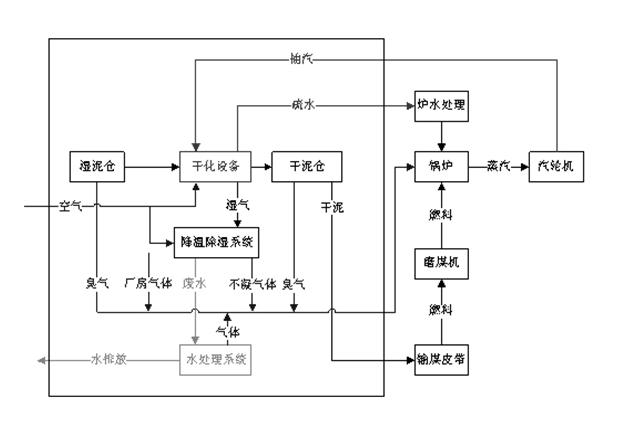

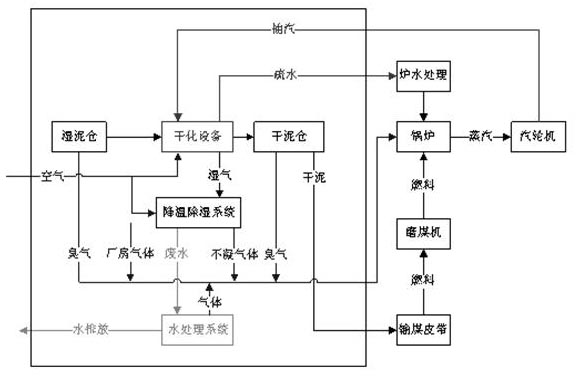

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The wet sludge is dumped into the wet sludge storage bin through the sludge transport vehicle. The upper part of the wet sludge storage bin is a half-closed half-open device. After dumping, the bin cover is automatically closed. A sieve plate is set above the wet sludge bin to prevent large pieces of foreign matter from entering the bin. At the same time, a sealed door is installed above the bin body to prevent odor from escaping, and a gas detection, collection and odor treatment system is also equipped.

[0014] Two double-screw pre-pressing conveyors are installed at the bottom of the sludge bin to output wet sludge. The outlet of each double-screw conveyor is connected to a sludge pump. After the wet sludge is pressurized by the sludge pump, it is transported to the The flow regulating valve continuously, at an even speed and with a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com