Medical moist composite dressing and preparation method thereof

A manufacturing method, wet technology, applied in medical science, non-woven fabrics, textiles and papermaking, etc., can solve the problems that cannot meet the needs of wound healing, and achieve the effect of less replacement times, less damage, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

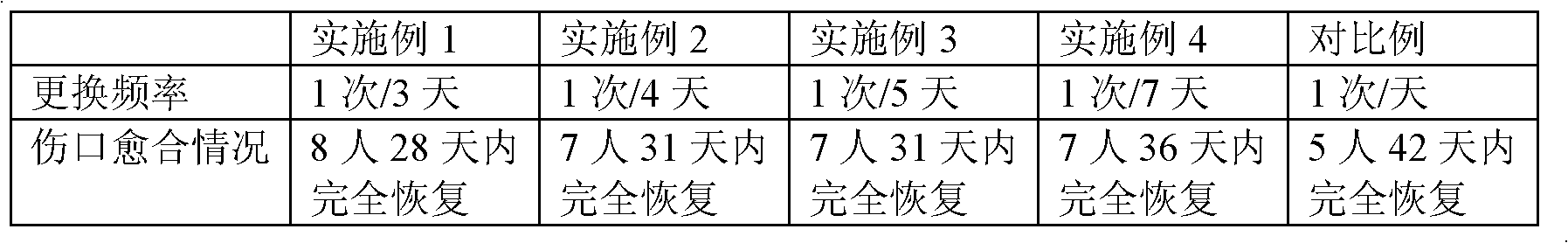

Examples

Embodiment 1

[0029] First, the polylactide slices are dried under vacuum (vacuum degree 750-760 mmHg) for 12 hours at a drying temperature of 120° C., and the moisture content of the slices is <80 ppm after drying. The dried polylactide slices are extruded by screw on the spinning and drawing machine, drawn in two stages, and wound to obtain polylactide filaments. The screw temperatures are: 220°C in zone 1 and 2 zones in zone 2. 230°C, 230°C in zone 3, 240°C in zone 4; the rotation speed of the spinning melt pump (0.3cc) is 16r / min; the temperature and speed of the first drafting roller are 50°C and 120m / min respectively; The temperature and speed of the rolls were 70°C and 380m / min respectively; the temperature and speed of the third drafting roll were 120°C and 600m / min respectively; the winding speed was 580m / min. The obtained fiber has a breaking strength of 5.8cN / dtex, a breaking elongation of 22.0%, and a strength retention rate of 30-50% within 2 weeks. The obtained polylactide fi...

Embodiment 2

[0032] According to the same method as described in Example 1, the polylactide staple fiber of monofilament 5dtex and 76mm is obtained, and the polylactide staple fiber and sodium alginate staple fiber (single filament fineness 1.5dtex, fiber length 10mm, fracture Strength 1.5~3.5cN / dtex) is pre-mixed according to the weight ratio of 30:70, and then through opening, mixing, carding, laying, pre-needling, lower main needle, upper main needle, heat treatment (110°C), molding, processing into needle-punched non-woven fabrics. Among them, the density of the medical composite dressing is controlled to 140g / m by adjusting the thickness of the net 2 , The water absorption rate reaches more than 10 times, and the bidirectional elongation at break> 30%. Adjust the pH of the medical composite dressing to 6.0-8.0, and then carry out gamma ray disinfection.

Embodiment 3

[0034] According to the same method as described in Example 1, obtain monofilament 2.5dtex, polylactide staple fiber of 38mm, polylactide staple fiber and sodium alginate staple fiber (single filament fineness 2dtex, fiber length 8mm, fracture Strength 1.5~3.5cN / dtex) pre-mixed according to the weight ratio of 40:60, and then through opening, mixing, carding, laying, pre-needling, lower main needle, upper main needle, heat treatment (140°C), molding, processing into needle-punched non-woven fabrics. Among them, the density of the medical composite dressing is controlled to 160g / m by adjusting the thickness of the laying net 2 , The water absorption rate reaches more than 10 times, and the bidirectional elongation at break> 30%. Adjust the pH of the medical composite dressing to 6.0-8.0, and then carry out gamma ray disinfection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com