Wood chip drying system for drying wood chip and associated method for drying wood chip

A drying system and sawdust technology, applied in wood drying, drying solid materials, drying chambers/containers, etc., can solve the problem of high cost, achieve the effects of reducing emissions, improving adsorption capacity, and improving availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

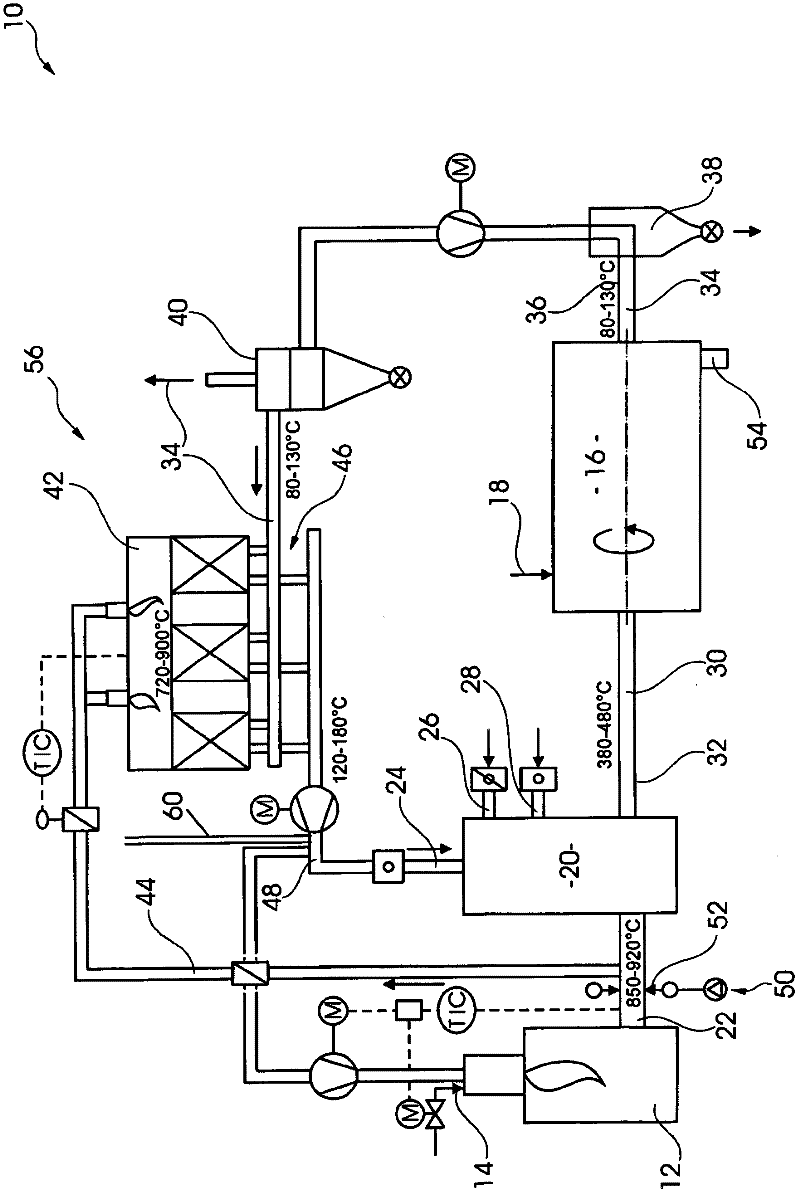

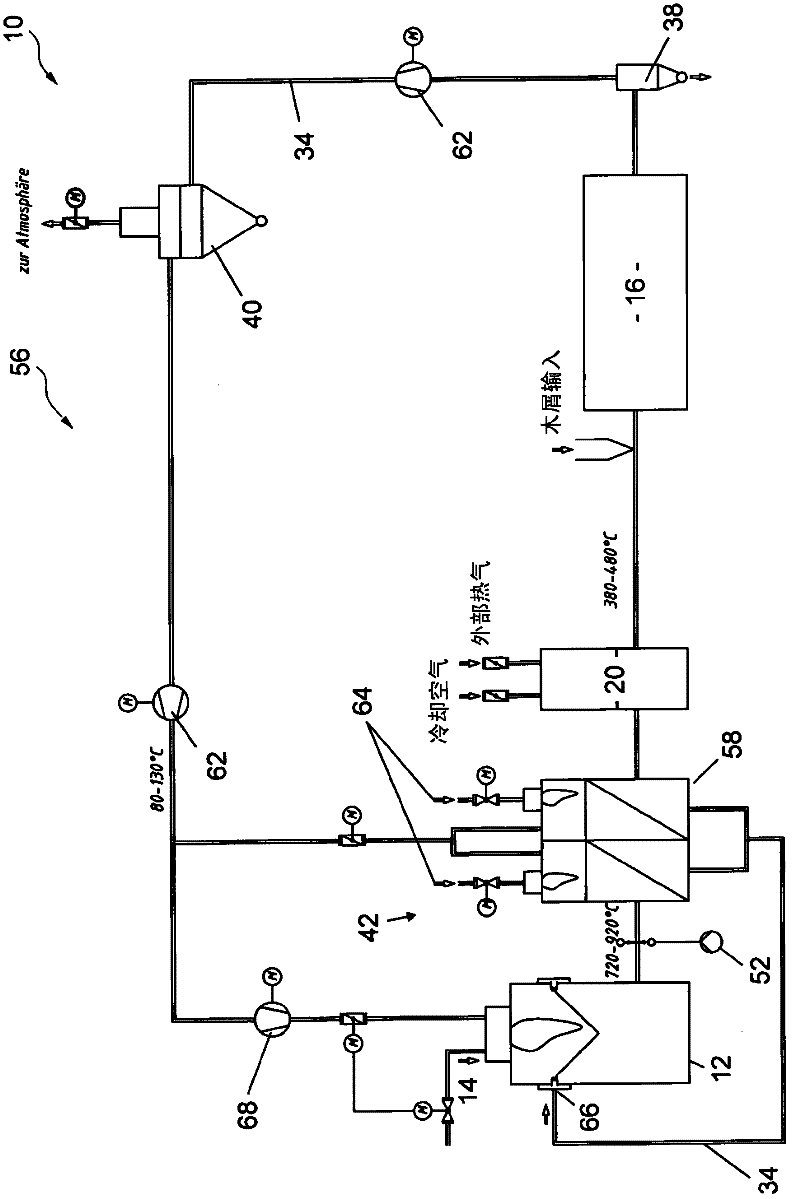

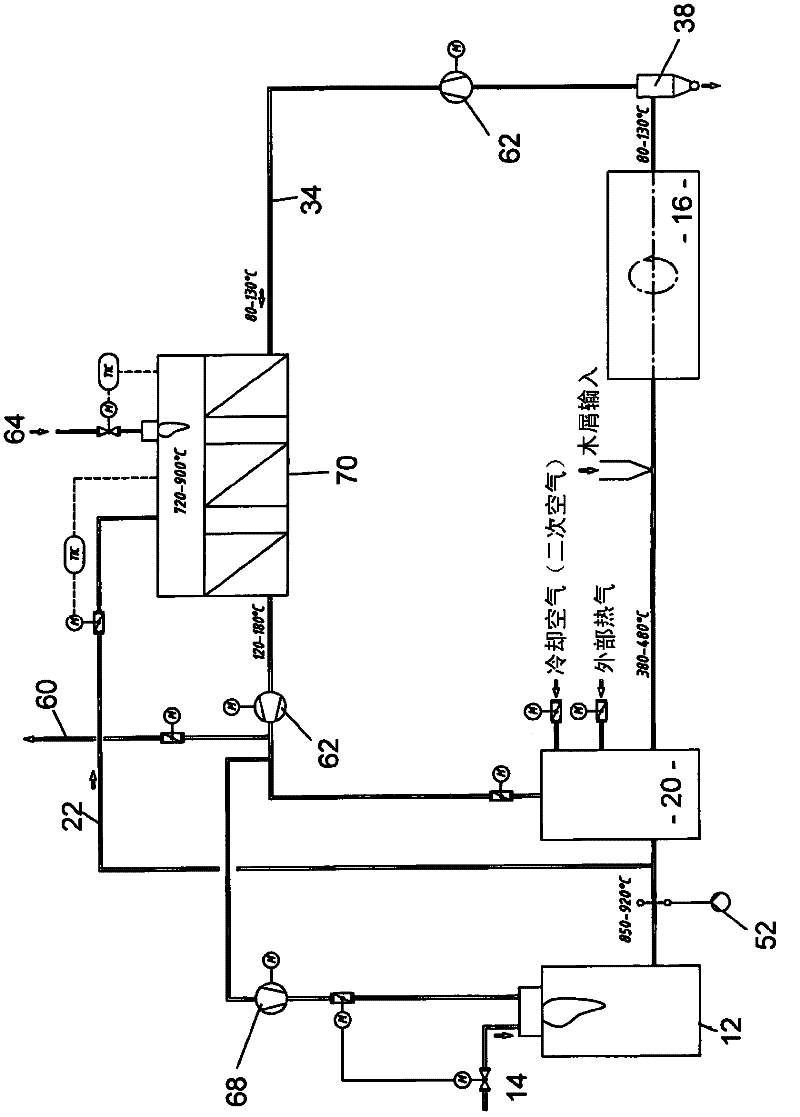

[0054] attached figure 1 Shown is a wood chip drying system 10 having a combustion device 12 to which is supplied wood dust 14 , shown schematically in the figure. The chip drying system 10 also includes a dryer 16 to which chips 18 are supplied from the chip supply. The dried chips leave the dryer 16 via a discharge device 19 .

[0055] The chip drying system has a mixing chamber 20 into which flue gases 22 from the combustion device 12 are fed. Furthermore, a first vapor line 24 , a cooling air line 26 and a hot gas line 28 lead into the mixing chamber 20 . The mixing chamber 20 is designed to deliver a drying gas 30 in a drying gas line 32 , wherein the drying gas 30 has a predetermined temperature and a predetermined absolute humidity.

[0056] Vapor 34 exits dryer 16 via vapor discharge line 36 leading to first cyclone separator 38 and then to second cyclone separator 40 . Part of the residual steam is separated from the residual steam discharge pipeline 36 and sent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com