Continuous delay coking device and method

A technology of delayed coking and process method, which is applied in the field of delayed coking equipment, can solve the problems that the switching period of the coke tower cannot be too short, consume too much water, steam and electricity, and increase the difficulty of design and manufacture, so as to improve the processing capacity and liquid The effect of product yield, simplification of operation, and improvement of economic benefits of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

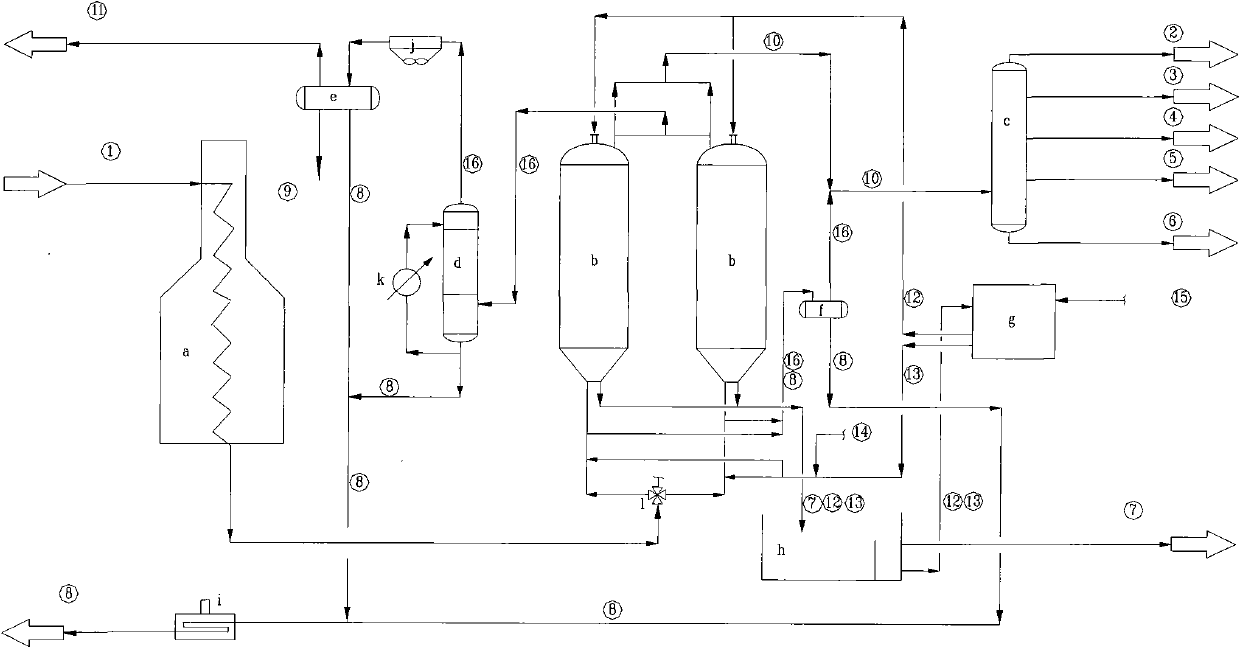

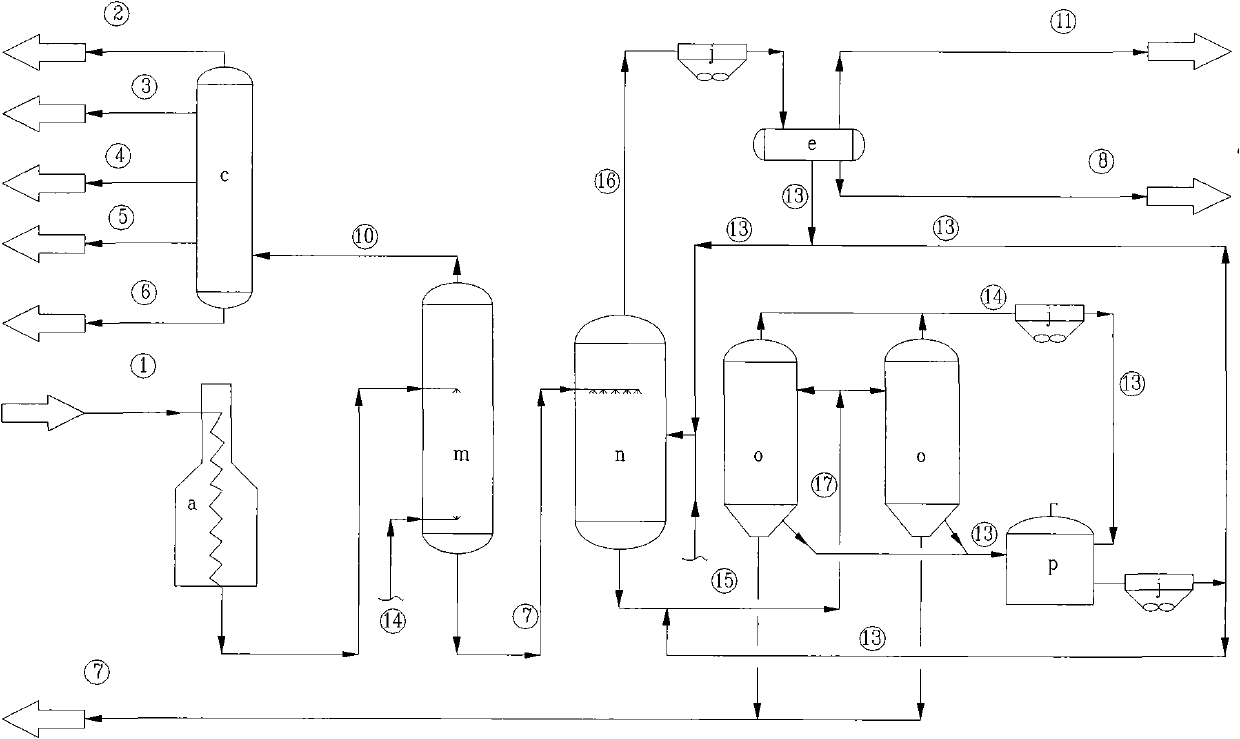

[0063] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0064] Such as figure 2 As shown in the continuous delayed coking process flow, the coking feedstock oil 1 enters the coking heating furnace a and heats the furnace to about 500°C, and then continuously enters the coking reactor m for cracking and condensation reactions, and the generated high-temperature oil gas 10 enters the fractionation tower c, Gas 2, naphtha 3, diesel oil 4, wax oil 5 and cycle oil 6 are fractionated in the fractionating column c. The produced coke 7 stays in the lower part of the coking reactor m for a certain period of time, and after being stripped by steam 14, it is pumped into the coke quenching tower n equipped with cold coke water 13, and the coke 7 is cooled and formed into a solid in the coke quenching tower n. The water is partially vaporized and together with the oil and gas evaporated from the coke, enters the air cooler f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com