Composition with ceramic heat dissipation effects

A composition and beneficial technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problem that radiators cannot cope with heat dissipation work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

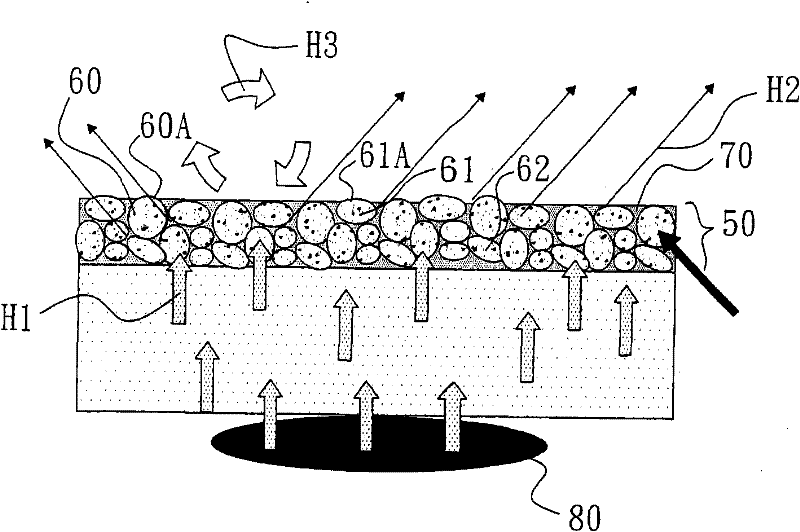

[0039] figure 2 It is a heat dissipation diagram of the composition of the present invention having the effect of ceramic heat dissipation. It can be seen from the figure that the composition 50 of the present invention has the effect of heat dissipation of ceramics. Composed of particles 60, 61, 62, especially the ceramic particles 60, 61, 62 are first treated with interface activation, so that when the ceramic particles 60, 61, 62 are in granular form, they can be fully bonded with the metal 70, except In addition to the good heat conduction ability H1 of the metal 70, the heat radiation ability H2 can also be enhanced by the encased ceramic particles 60, 61, 62, and the metal 70 is sintered into a metal solution in a granular form to cover and adhere to the ceramic particles 60 , 61, after refill molding, the whole surface in contact with the outside atmosphere will scatter a number of ceramic particle tops 60A, 61A protruding irregularly, increasing the fine convective he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com