Method for synthesizing high tap density spinel material LiNi0.5Mn1.5O4

A technology of tap density and spinel, which is applied in the direction of manganate/permanganate, etc., can solve the problems that lithium nickel manganese oxide is not easy to increase the tap density of products, limit the application of electrode materials, and cause safety hazards of combustion and explosion. To achieve the effects of easy control of the process, no safety accidents, and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

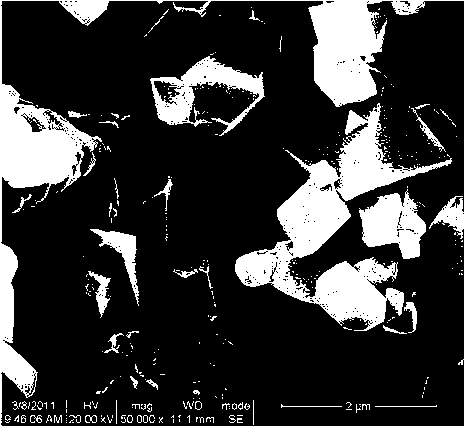

Image

Examples

Embodiment 1

[0028] Taking lithium carbonate, nickel nitrate, manganese, citric acid, and ice acetic acid as the raw material, and water as a dispersant, the ratio of li: NI: Mn is 1: 0.5: 1.5 mix (Moore ratio, the same below).First add a sufficient amount of methamphetamine to the lithium carbonate to form lithium acetate, then add it to the nickel nitrate solution, then add manganese and citric acid to the above solution, stir and heat upDry forming powder, burn the powder for 3 hours under 350 ° C and burn at 750 ° C for 12 hours to get the final product. The vibration density is 2.3g / cm 3 EssenceThe product is assembled into a battery test, and the test ratio is 145mAh / g at 0.2C between 3.5V and 5.2V, the capacity of the test ratio of 10C is 121mAh / g under 10C conditions, and the capacity of 800 under 2C loop remains maintained.The rate is more than 88%.

Embodiment 2

[0030] Taking lithium carbonate, nickel nitrate, manganese, citric acid, and ice acetic acid as the raw material, and water as a dispersant, the ratio of LI: NI: Mn is 1.05: 0.5: 1.5 (Moore ratio, the same below).First add a sufficient amount of methamphetamine to the lithium carbonate to form lithium acetate, then add it to the nickel nitrate solution, then add manganese and citric acid to the above solution, stir and heat upDrying forms powder, burn the powder at 450 ° C for 1 hour and burn at 800 ° C for 12 hours to get the final product. 3 EssenceThe product is assembled into a battery test, and the test ratio is 143mAh / G under 0.2C between 3.5V and 5.2V, the capacity of the test ratio is more than 117mAh / g under 10C conditions, and the capacity of 100 times after 2C is maintained.The rate is more than 90%.

Embodiment 3

[0032] Taking lithium carbonate, nickel nitrate, manganese, citric acid, and ice acetic acid as the raw material, and water as a dispersion, the ratio of LI: NI: Mn is 1.: 0.52: 1.5 mix (Moore ratio, the same below).First add a sufficient amount of methamphetamine to the lithium carbonate to form lithium acetate, then add it to the nickel nitrate solution, then add manganese and citric acid to the above solution, stir and heat upDrying forms powder, burned the powder for 1 hour at 550 ° C and burned for 3 hours at 800 ° C to get the final product. The vibration density is 2.38g / cm 3 EssenceThe product is assembled into a battery test, and the test ratio is 146mAh / g at 0.2C between 3.5V and 5.2V, the capacity of the test ratio of 119mAh / G under 10C conditions is over 119mAh / g, and the capacity of 500 under 2C is maintained.The rate is more than 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com