Method for manufacturing tungsten target material

A production method and target technology, which are applied in the field of tungsten target production, can solve the problems of expensive molds, easy wear and tear, and the uniformity of the internal structure of tungsten targets cannot meet the requirements of increasingly high sputtering processes. Excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

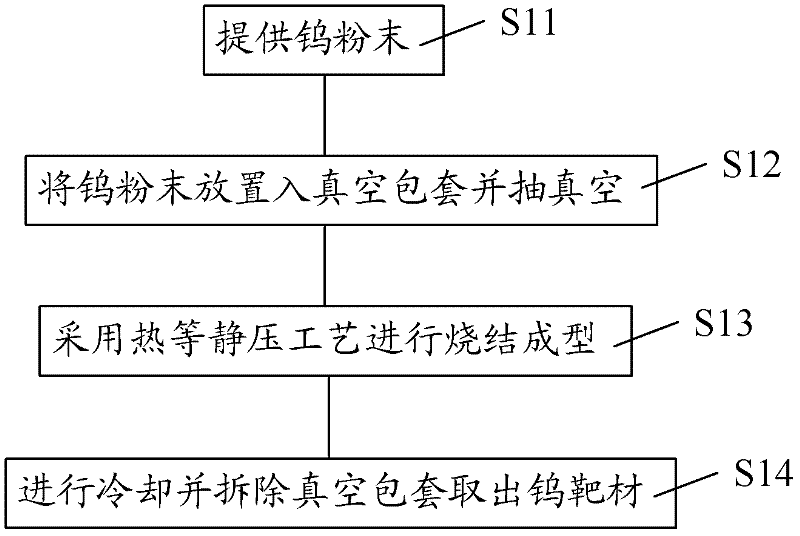

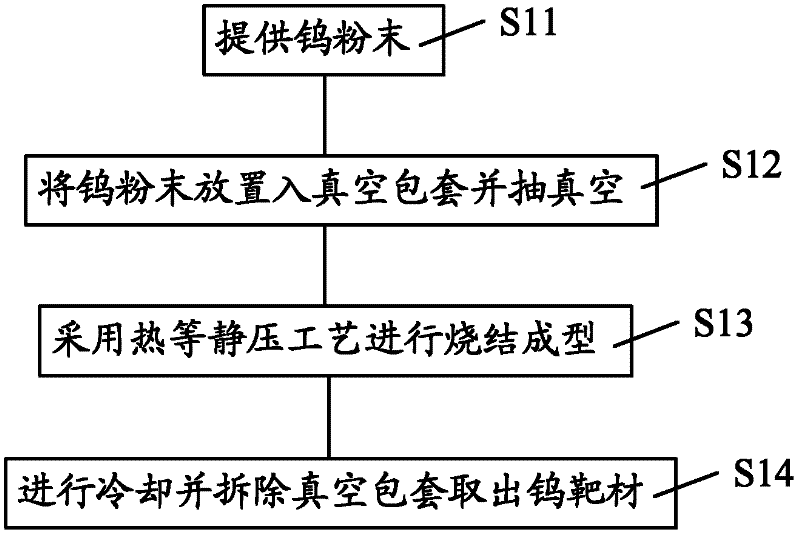

[0026] As described in the background technology, the uniformity of the internal structure of the tungsten target processed by the existing hot pressing process cannot meet the increasingly demanding sputtering process. Pressure is applied in a certain direction (for example, vertical direction), which makes the powder grains be subjected to uneven force in each direction when they are formed into targets. Therefore, the present inventors proposed to adopt the hot isostatic pressing method in the sintering molding process. Specifically, the manufacturing method of the tungsten target provided by the present invention includes: firstly adopting a vacuum sheath to seal the tungsten powder; then adopting a hot isostatic pressing process for sintering; after the sintering is completed, cooling and removing the vacuum sheath to take out the tungsten target In the process of forming a tungsten target by the above method, the use of a mold is avoided. At the same time, the density an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com