Multi-media surface coating spraying coater

A spraying machine and multi-media technology, applied in the direction of coating, surface coating liquid device, spraying device, etc., can solve the problem of affecting the accuracy and working efficiency of the spraying machine, affecting the service life of the motor and oil pump, and increasing the maintenance cost of the spraying machine and other issues, to achieve the effect of shortening the length of the fuselage, compact structure, and reducing the occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

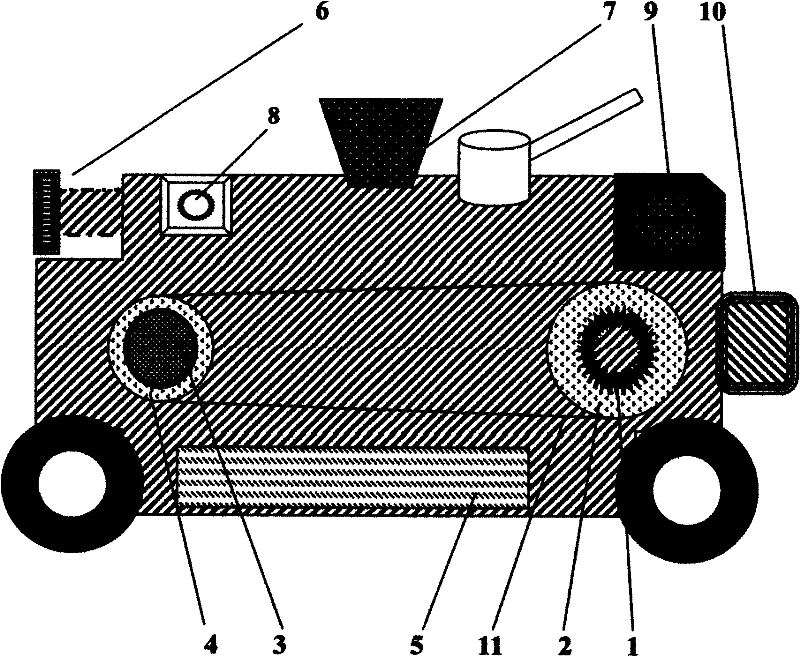

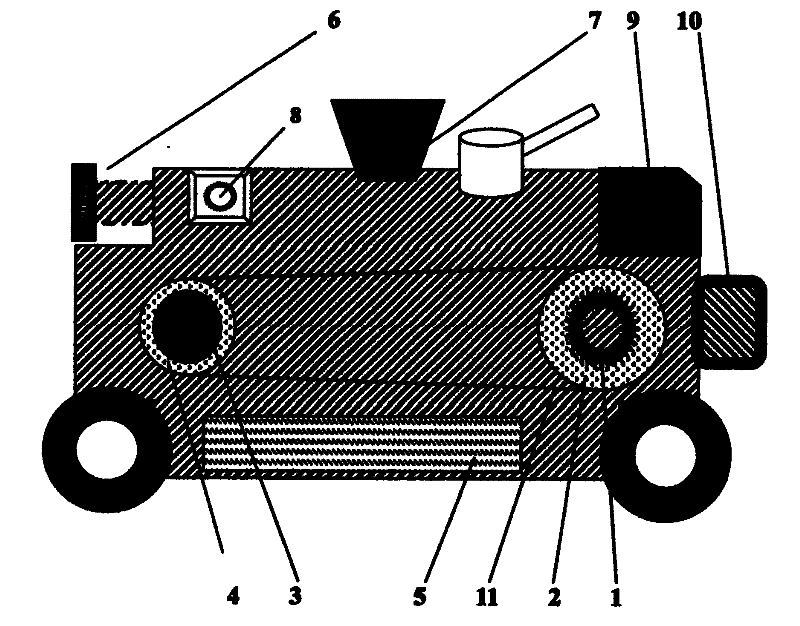

[0016] Sprayer control method: such as figure 1 Shown, a kind of multi-media surface coating spraying machine, its hydraulic control system is composed of remote control device (10), servo motor (1), pressure increase and decrease sensor (8) and oil pump synchronous pulley (4), and through The switch handle (6) is used to control the running components (7) of the spraying machine, and the pressure in the hydraulic system is fed back to the remote control device (10) through the increase and decrease sensor (8), and then the servo motor is fed back by the data sheet (9). The rotational speed of (1) is fed back to the remote control device (10), and the control signal is transmitted to the servo motor (1) after being processed by the remote control device (10), thereby adjusting the output pressure and flow rate of the synchronous pulley (4) of the oil pump.

Embodiment 2

[0018] The connection method between the motor and the oil pump: such as figure 1 As shown, the driving mechanism of the spraying machine includes a servo motor (1) and an oil pump synchronous pulley (4), and the servo motor (1) and the oil pump synchronous pulley (4) are connected to the servo motor drive wheel (2 ) and the timing belt shaft (3), the timing belt shaft (3) is inserted into the oil pump timing pulley (4).

[0019] The above-mentioned shaft and wheel connection method adopts a toothed synchronous wheel, the inner shaft and the outer wheel are directly connected, the servo motor drive wheel (2) adopts an inner toothed synchronous wheel, and the synchronous belt shaft (3) adopts an outer toothed synchronous belt shaft. This way the connection is better and more stable.

[0020] The above-mentioned shaft-wheel connection can also adopt other forms of spline connection and gear connection.

[0021] A multi-media surface coating spraying machine, because it include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com