Post type lithium battery cover plate

A lithium battery and pole technology, applied in the field of pole-type lithium battery cover plates, can solve the problems of inconvenience, low self-discharge rate, short circuit, etc., and achieve the effect of avoiding short circuit, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

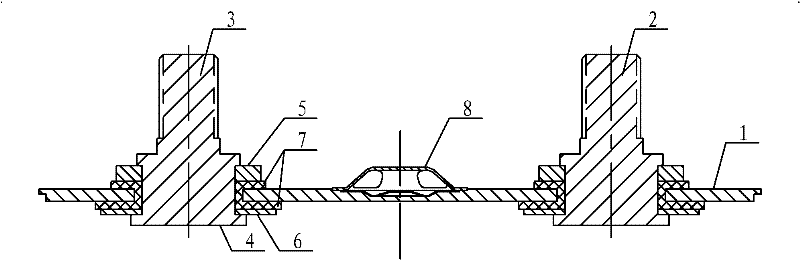

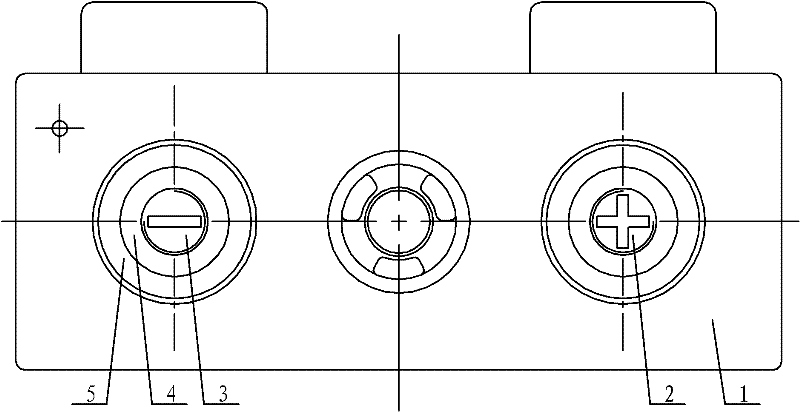

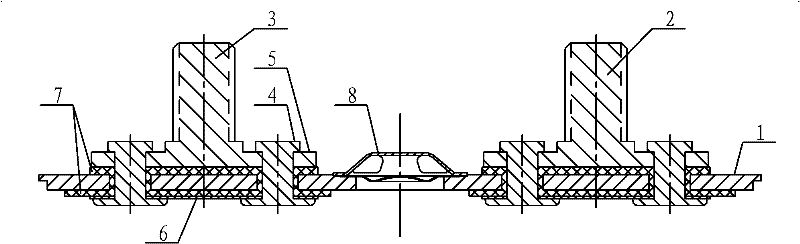

[0018] Such as Figure 1~2 In the shown embodiment, the pole type lithium battery cover plate according to the present invention includes a base plate 1, an explosion-proof hole is opened in the center of the base plate 1, and positive and negative pole posts 2 and 3 mounting holes are opened on both sides, and the positive and negative pole posts 2 , 3. One end goes through the installation hole, and the other end is connected to the substrate 1 through the rivet 4 and the electrode pressing plate 5. The electrode pressing plate 5 is arranged on the upper joint surface of the rivet 4 and the substrate 1. The electrode pressing plate 5 is a circular pressing plate, and corresponds to The center of the rivet 4 and the pole are on the same straight line, the lower joint surface of the rivet 4 and the substrate 1 is provided with an electrode lead piece 6, and the connection between the electrode pressure plate 5, the electrode lead piece 6 and the substrate 1 is provided with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com