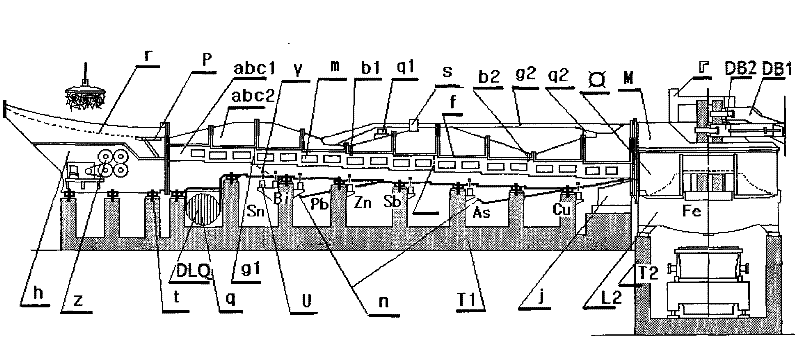

SPAAF (Super power alternating arc furnace) system

A structural method and full-short network technology, which is applied in the field of electric arc metallurgy charge and full tooling, can solve the problems of lack of implicitness, lack of deep technology, development of empty talk and reality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] Specific embodiments of the present invention will be further described below in conjunction with accompanying drawing:

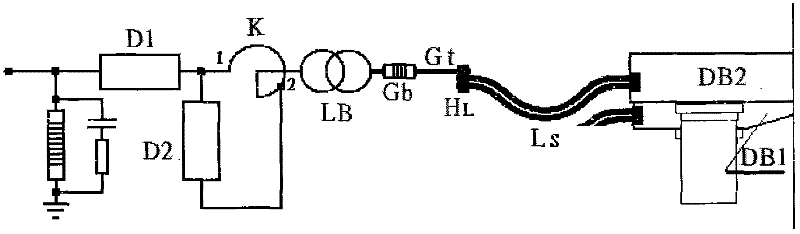

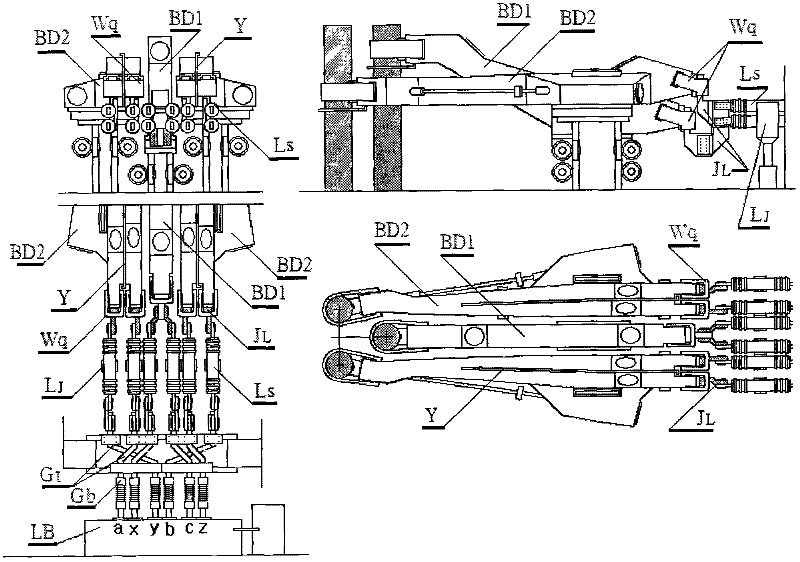

[0122] Through the identification of the [solid-liquid / long-short] dual-sequence process characteristics of the electric arc furnace [smelting-repair], and the adaptive construction of the [full-short network] resistance / anti-arc characteristics, the K anti-[serial -Short] Transition simple and convenient operation, in solid melting and arc strike harmonic timing, limit the current with full K to allow in [force change], complete the large-cycle initial pool and temporary induction; and in the liquid continuous smelting sequence, short D2 The arc control flow is used for smelting; and the online ultra-short horizontal suspension cable distribution of [smelting-repair] is realized with the Wq [quick continuation] structure; network, realize the full balance of the static and dynamic impedance of the optimized [average distance / inertial distance] short...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com