High-efficient combustion furnace with self-steam-supplying combustion-supporting function

A combustion furnace and steam technology, applied in the field of combustion furnace, can solve the problems of unclean use of combustion furnace, scattered coal ash, unhealthy working environment, etc., and achieve the effect of reducing fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

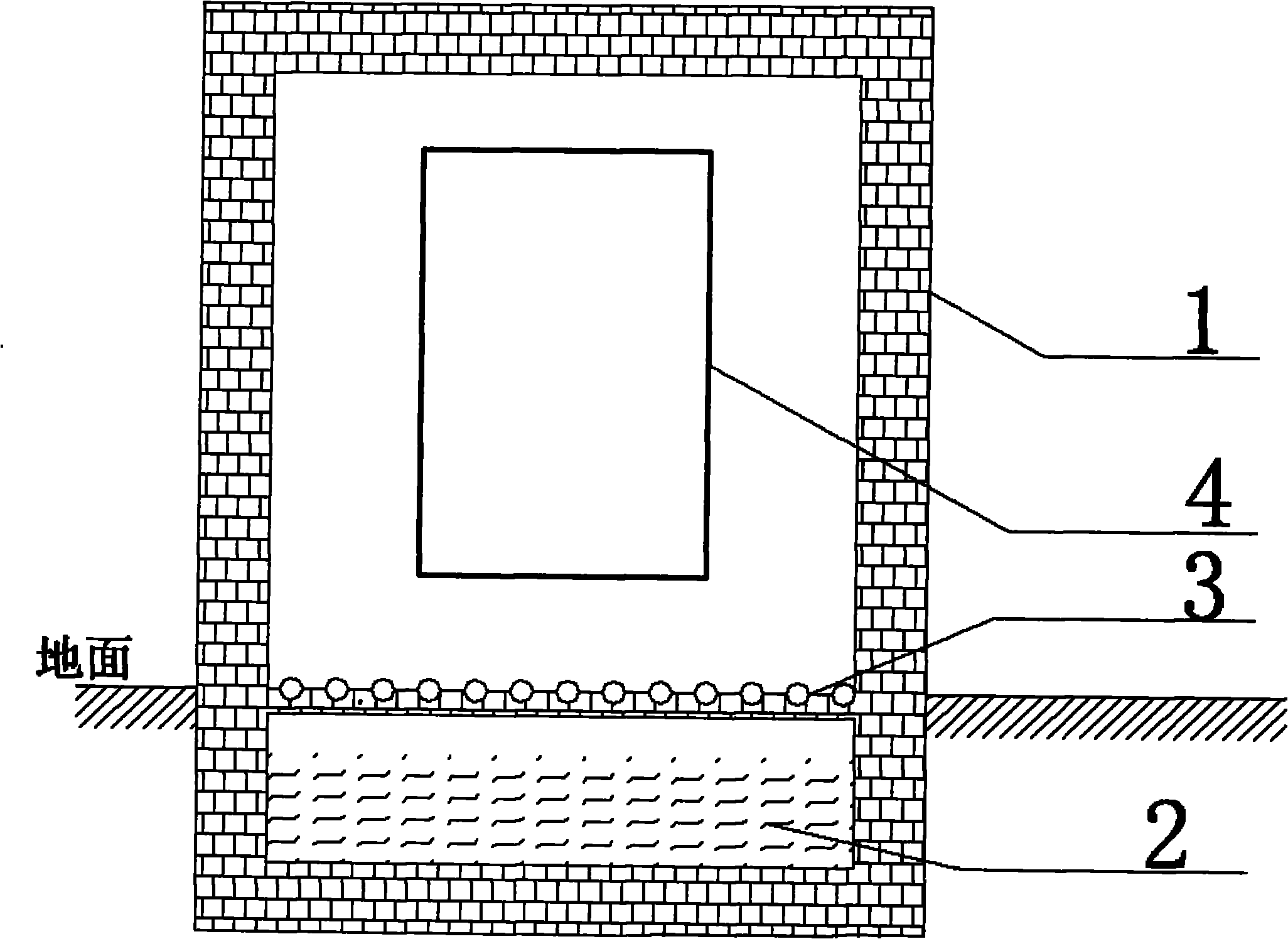

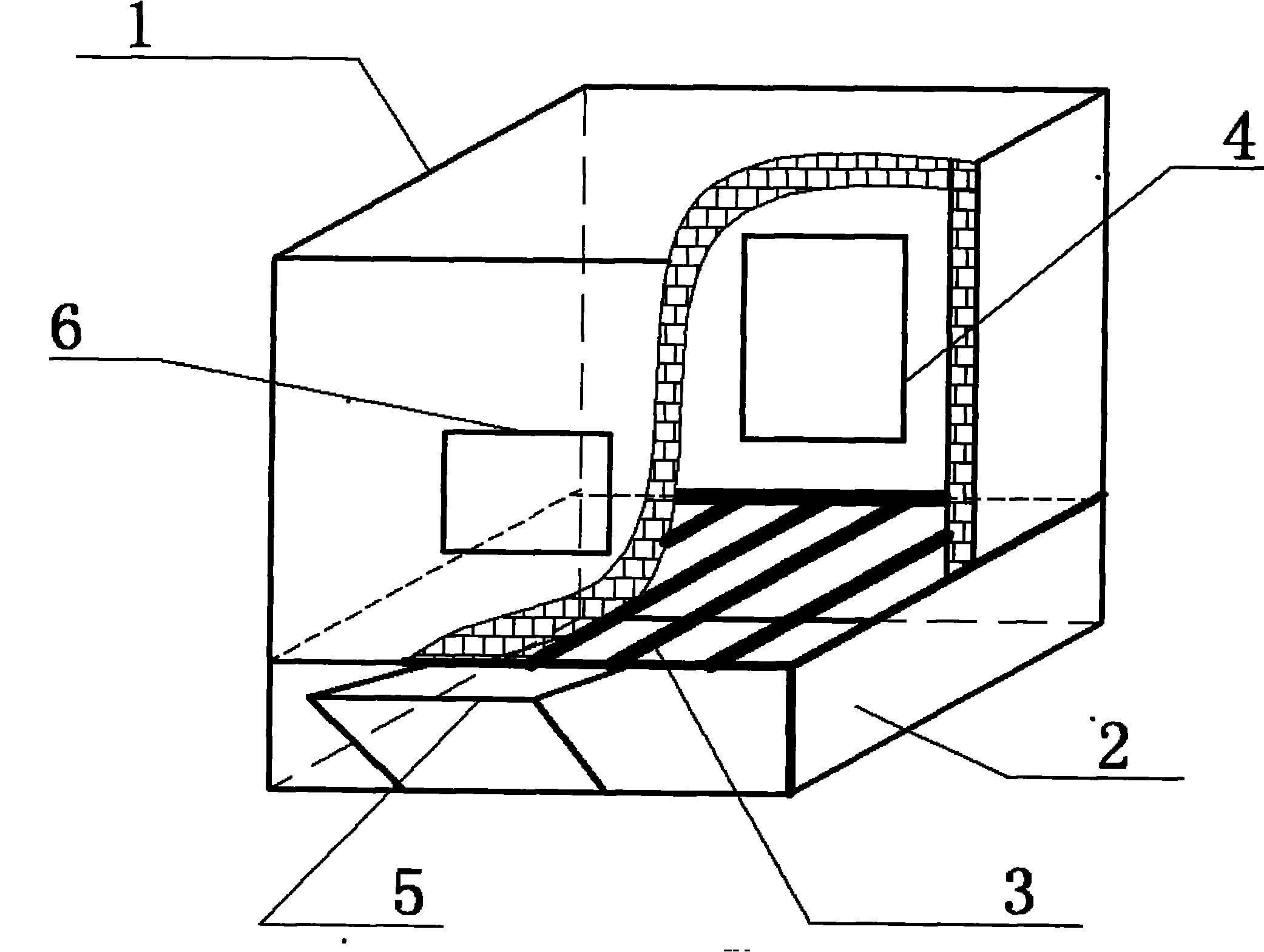

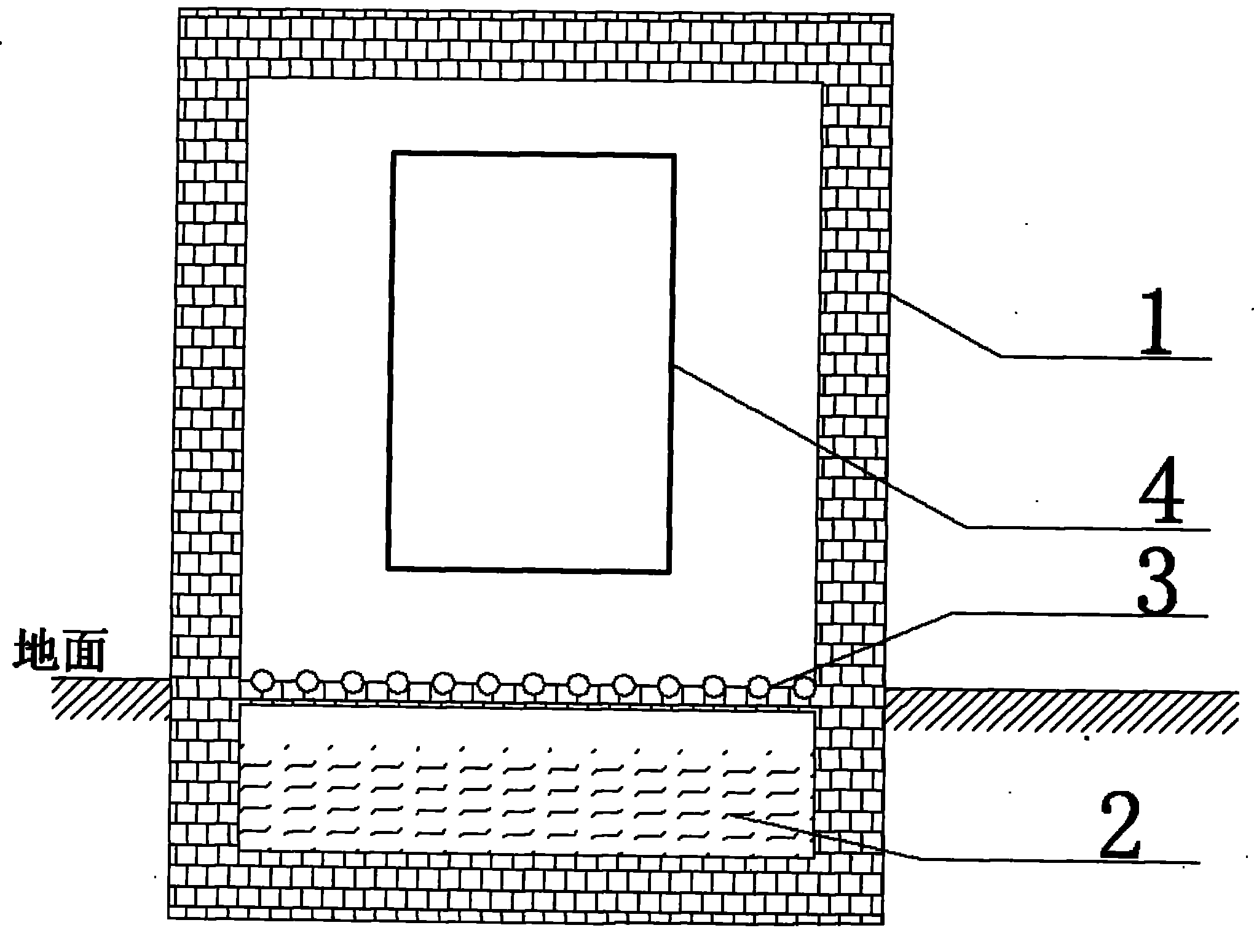

[0017] As shown in the figure, the present invention mainly comprises body of heater 1 and pool 2, wherein:

[0018] The furnace body 1 includes a fire grate 3, a smoke exhaust hole 4 at the rear and a furnace door 6 at the front; a slag cleaning water inlet 5 is provided at the front of the pool 2; the fire grate 3 is 50mm higher than the ground.

[0019] The smoke exhaust hole 4 transfers the heat energy generated by the combustion in the furnace body 1 to other equipment; the furnace door 6 adds coal or removes slag;

[0020] The slag-cleaning water inlet 5 is mainly to clean up the burnt slag. Since the outside world can communicate with the inside of the body of furnace 1 through the slag-cleaning water inlet 5, the slag-cleaning water inlet 5 also provides part of the combustion air at the same time. It is preheated to about 100°C. In addition, the air intake can also be controlled by adjusting the size of the slag-cleaning water inlet 5 to ensure optimal operating effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com