Acid washing method of titanium and zirconium materials without acid-free fog

A pickling and acid mist technology, which is applied in the field of pickling of metal materials, can solve the problem of high processing cost, achieve the effects of less investment, simple operation process, and simple site requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

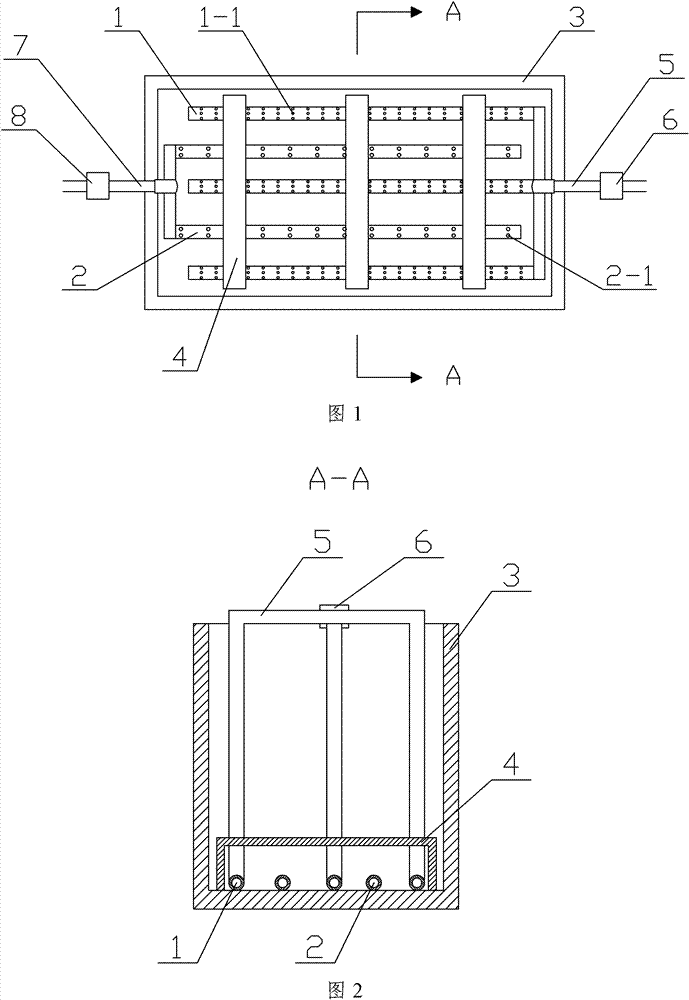

[0034] Step 1, such as figure 1 and figure 2 As shown, the horizontal section of the pipeline one 1 and the horizontal section of the pipeline two 2 are arranged in parallel in the pickling tank 3; the pipe wall of the horizontal section of the pipeline one 1 is uniformly provided with a through hole one 1-1, and the pipeline two Through-holes 2-1 are uniformly arranged on the pipe wall of the horizontal section of 2;

[0035] Step 2, put the support member 4 for supporting the titanium or zirconium material to be pickled into the pickling tank 3;

[0036] Step 3: Add water to the pickling tank 3 where the support 4 is placed in step 2, and then feed compressed air into the pipeline 1, the compressed air is blown into the water through the through hole 1-1, and at the same time, it is injected into the pipeline 2 2 Pass into nitric acid, nitric acid enters in the pickling tank 3 through the through hole 2-1 and is diluted in the water in the pickling tank 3, after passing t...

Embodiment 2

[0048] Step 1, such as figure 1 and figure 2 As shown, the horizontal section of the pipeline one 1 and the horizontal section of the pipeline two 2 are arranged in parallel in the pickling tank 3; the pipe wall of the horizontal section of the pipeline one 1 is uniformly provided with a through hole one 1-1, and the pipeline two Through-holes 2-1 are uniformly arranged on the pipe wall of the horizontal section of 2;

[0049] Step 2, put the support member 4 for supporting the titanium or zirconium material to be pickled into the pickling tank 3;

[0050] Step 3: Add water to the pickling tank 3 where the support 4 is placed in step 2, and then feed compressed air into the pipeline 1, the compressed air is blown into the water through the through hole 1-1, and at the same time, it is injected into the pipeline 2 2 Pass into nitric acid, nitric acid enters in the pickling tank 3 through the through hole 2-1 and is diluted in the water in the pickling tank 3, after passing t...

Embodiment 3

[0062] Step 1, such as figure 1 and figure 2 As shown, the horizontal section of the pipeline one 1 and the horizontal section of the pipeline two 2 are arranged in parallel in the pickling tank 3; the pipe wall of the horizontal section of the pipeline one 1 is uniformly provided with a through hole one 1-1, and the pipeline two Through-holes 2-1 are uniformly arranged on the pipe wall of the horizontal section of 2;

[0063] Step 2, put the support member 4 for supporting the titanium or zirconium material to be pickled into the pickling tank 3;

[0064] Step 3: Add water to the pickling tank 3 where the support 4 is placed in step 2, and then feed compressed air into the pipeline 1, the compressed air is blown into the water through the through hole 1-1, and at the same time, it is injected into the pipeline 2 2 Pass into nitric acid, nitric acid enters in the pickling tank 3 through the through hole 2-1 and is diluted in the water in the pickling tank 3, after passing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com