Film material processing device and vapor deposition equipment with same

A processing device and film material technology, applied in the field of evaporation equipment, can solve the problems of waste of processing time, non-dense internal structure, contamination of film material, etc., so as to avoid life and work efficiency, reduce waste of labor time, and improve evaporation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

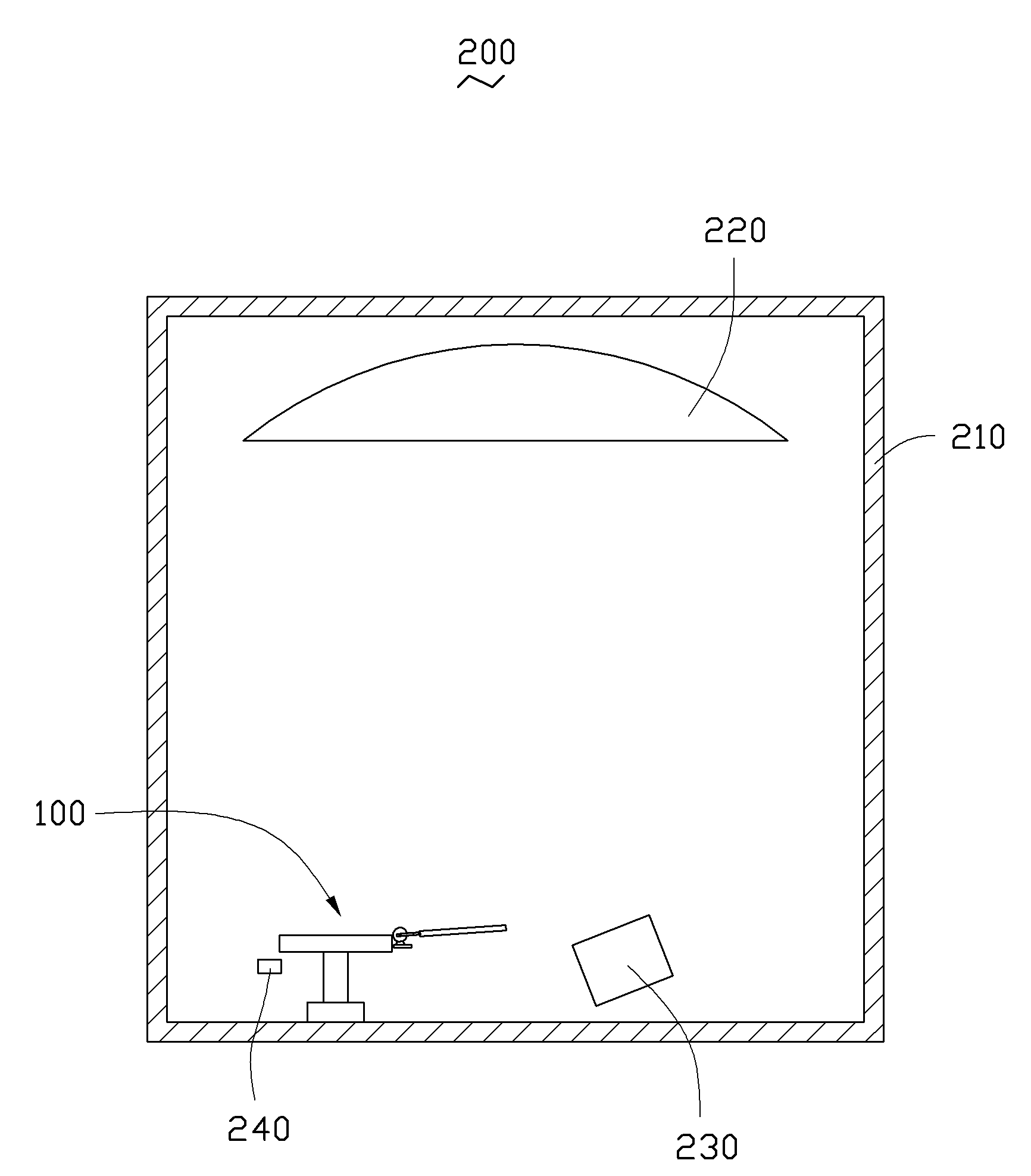

[0030] The technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

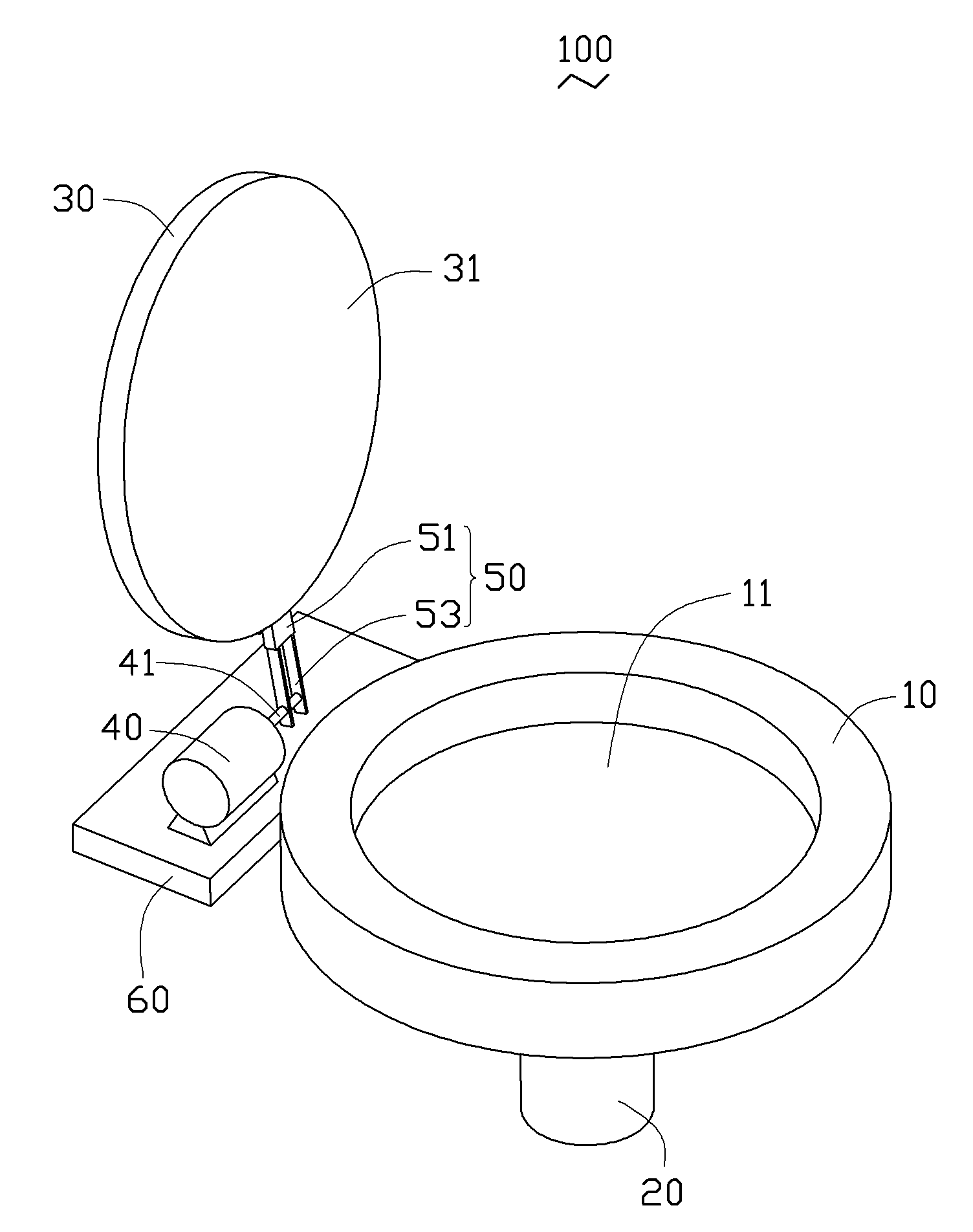

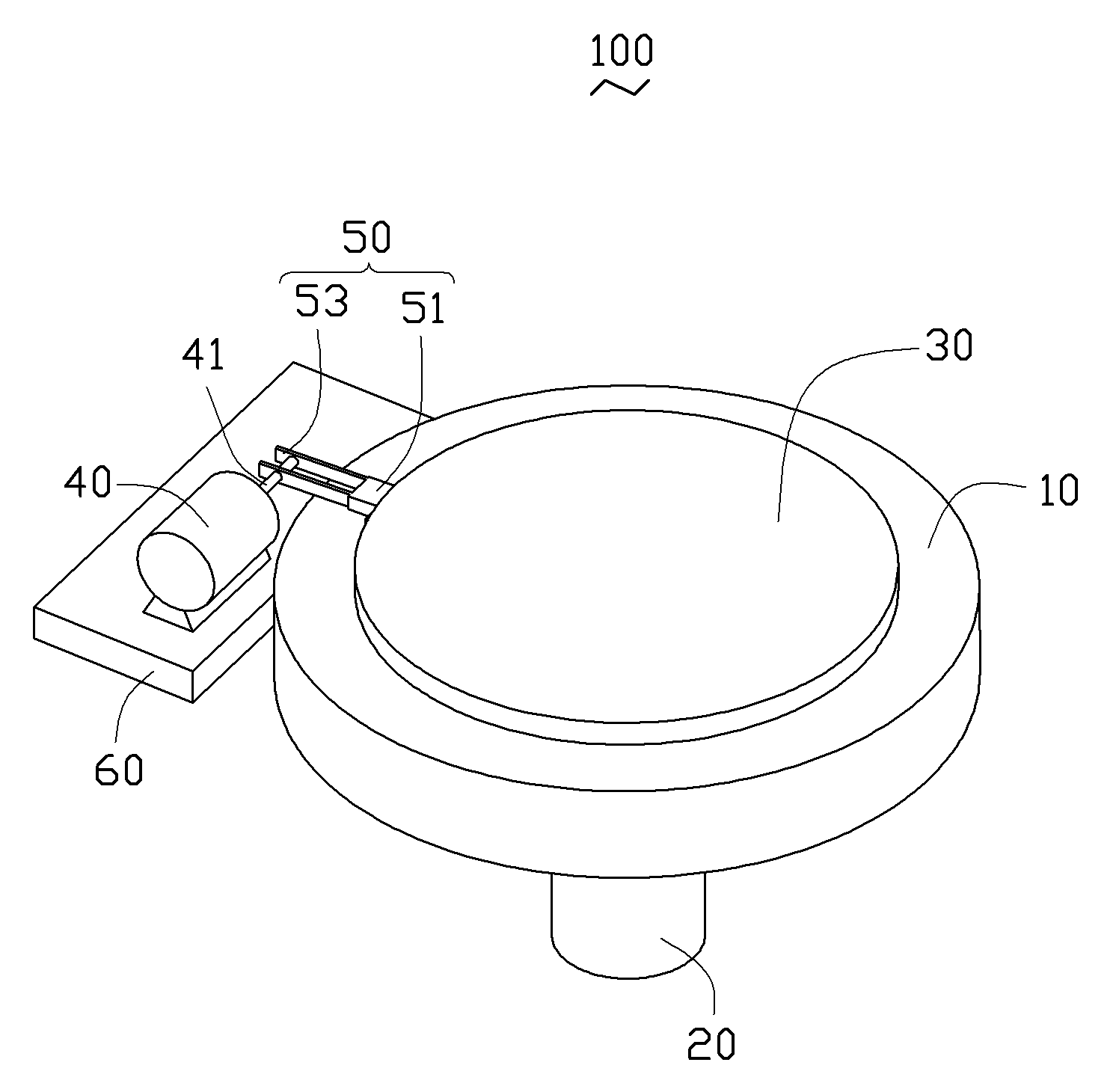

[0031] see figure 1 , the first embodiment of the present invention provides a film material processing device 100, which is used for flattening the evaporation film material, and the film material processing device 100 includes a crucible 10, a rotating shaft 20, a flattening cover 30, and a driver 40 .

[0032] The crucible 10 is used to hold film material raw materials and film materials (i.e. evaporation target material, not shown in the figure), and it has a housing hole 11 for containing film material raw materials or film materials, and the granular film material raw materials are placed in In the accommodating hole 11, the film material required for evaporation can be formed through vacuum heating. In this embodiment, the crucible 10 is a circular crucible, and the accommodating hole 11 is a circular hole. Certainly, the crucible 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com