Phase-change thermal storage material

A technology of phase change heat storage and weight percentage, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as unstable quality and limited storage energy of phase change materials, and achieve saving of fossil raw materials, phase change Large latent heat and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: take raw material according to following weight percentage:

[0015] Silicon dioxide 41%, alumina 4.8%, calcium oxide 0.8%, magnesium oxide 0.8%, potassium oxide 0.7%, sodium oxide 2.1%, iron oxide 0.6%, copper oxide 2.8%.

[0016] Put the above raw materials in a container, add 46.4% water by weight into the container, and stir evenly until they are evenly mixed.

Embodiment 2-3

[0017] Embodiment 2-3 is prepared by using the following raw materials in weight percentage, and the preparation method is the same as that of Embodiment 1.

[0018] raw material name Example 2 Example 3 silica 42% 37% Aluminum oxide 3.9% 7.9% Calcium Oxide 0.4% 1.2% magnesium oxide 0.6% 1.2% potassium oxide 0.6% 1.2%

[0019] sodium oxide 1.8% 2.4% iron oxide 0.4% 0.8% Copper oxide 2.8% 4.0% water 47.5% 44.3%

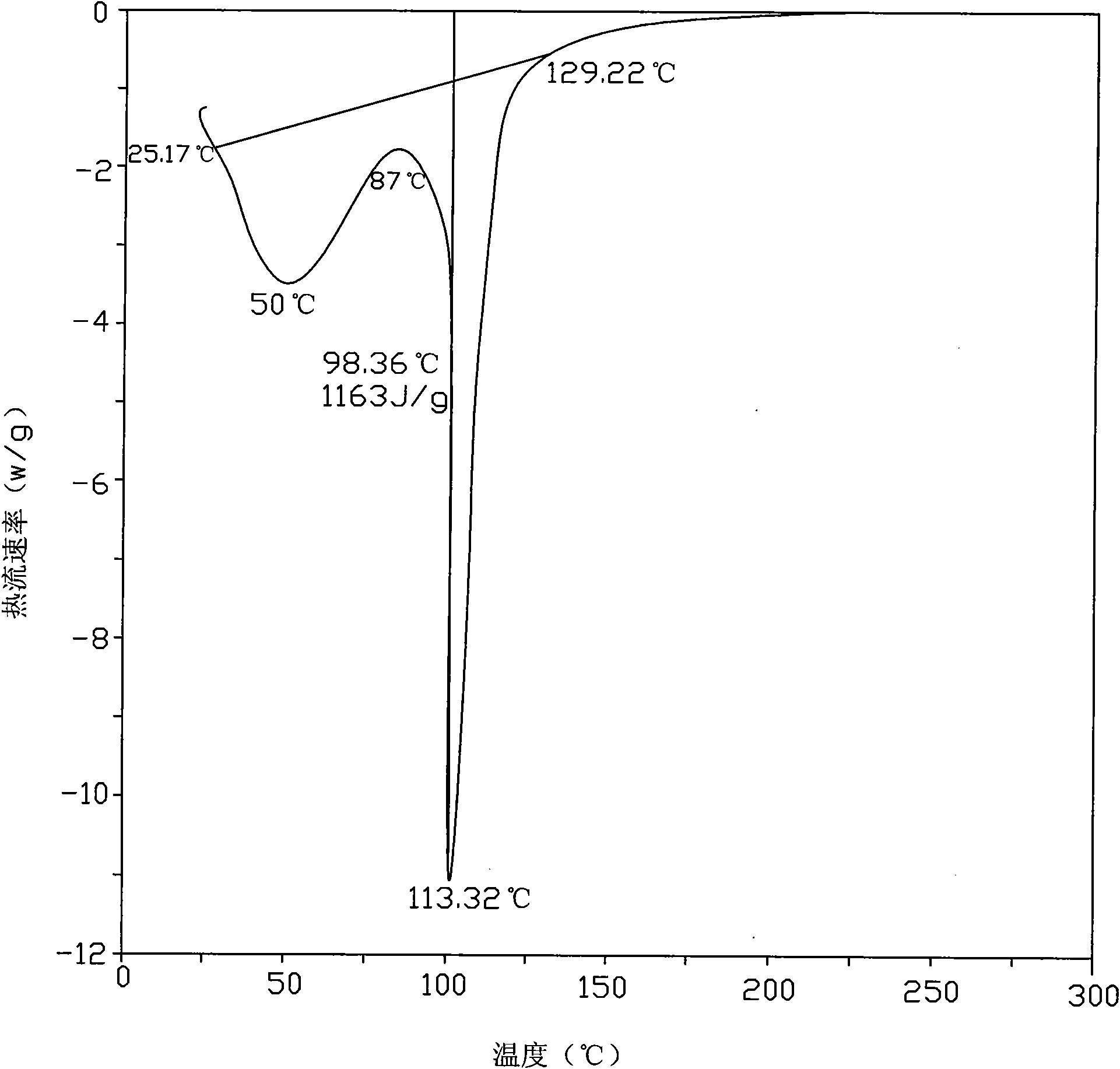

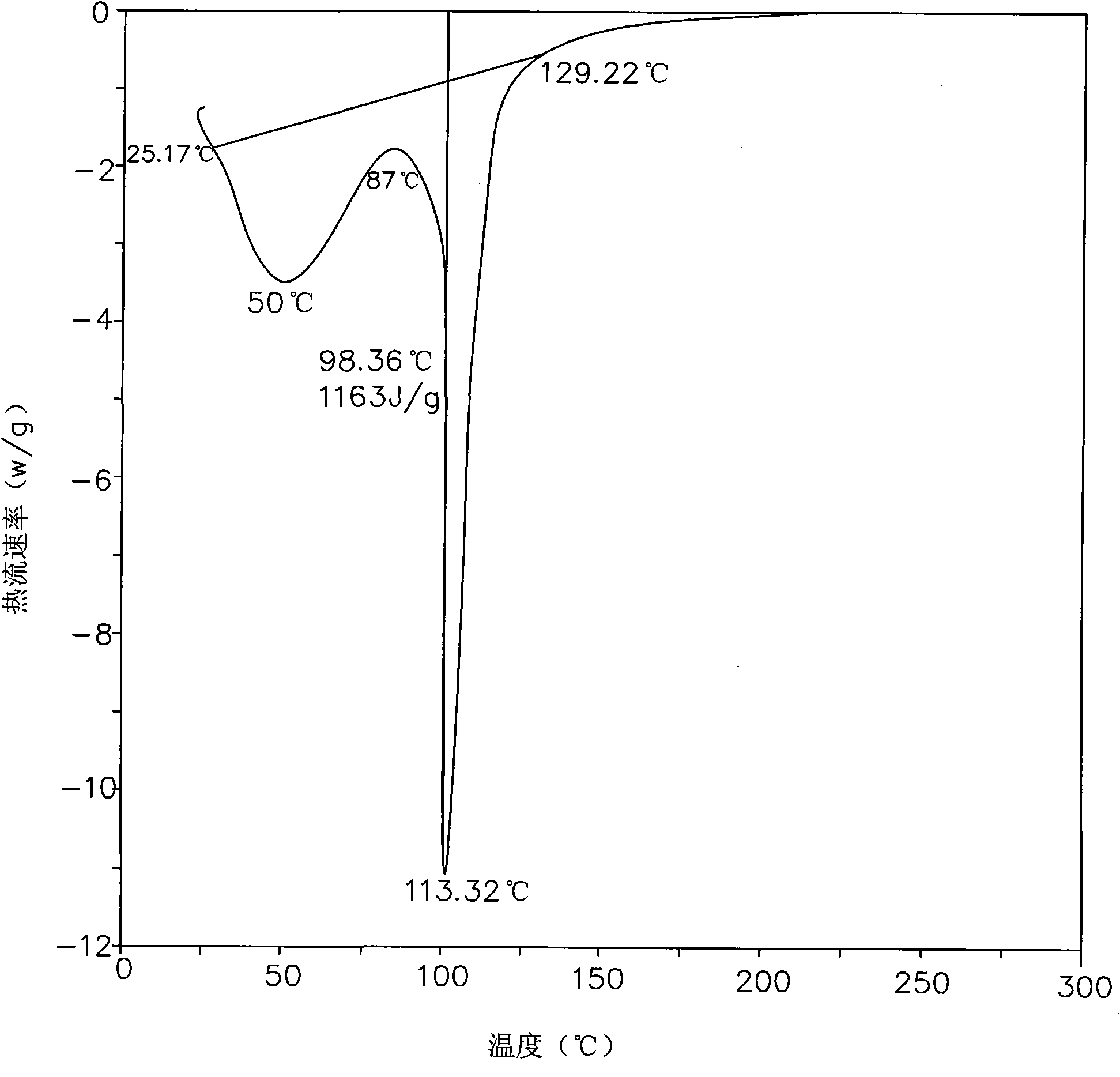

[0020] The phase change thermal storage material of the present invention is analyzed by a differential scanning calorimeter (DSC), and obtained as follows: figure 1 Performance curves of phase change thermal storage materials shown.

[0021] figure 1 It shows that in the temperature range of the external heat factor below 50°C, the phase change heat storage material of the present invention undergoes primary heat absorption, and in the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com