High transmittance toughenable low radiation glass and manufacture method thereof

A low-emissivity glass and high-transmittance technology, applied in the field of coated glass, can solve problems such as damage, loss of low-emission performance, and reduction of production capacity of coating lines, etc., and achieve the effect of low hemispheric emissivity and high visible light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

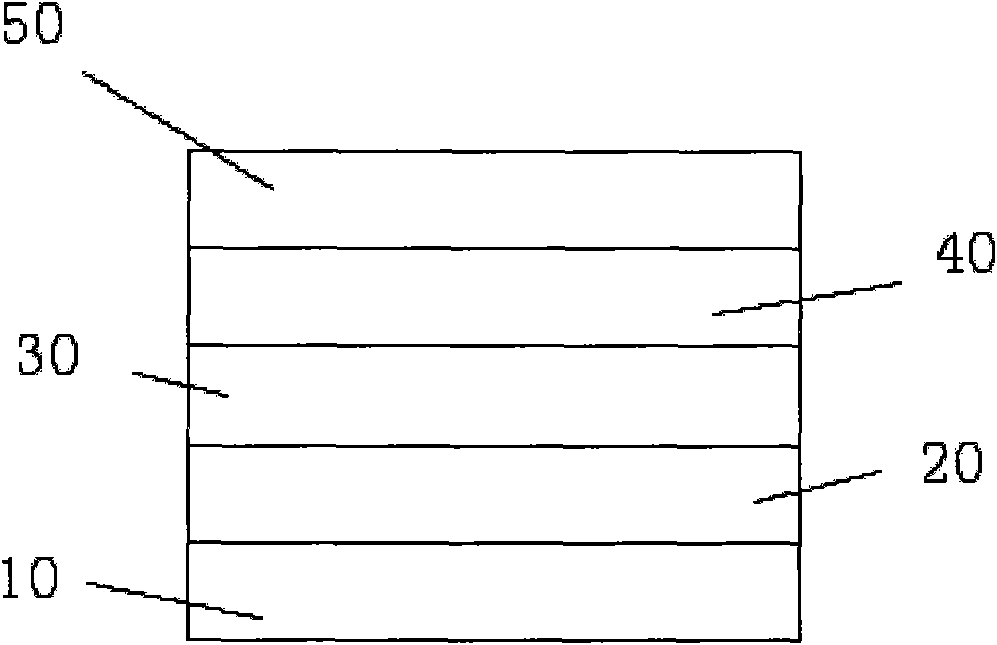

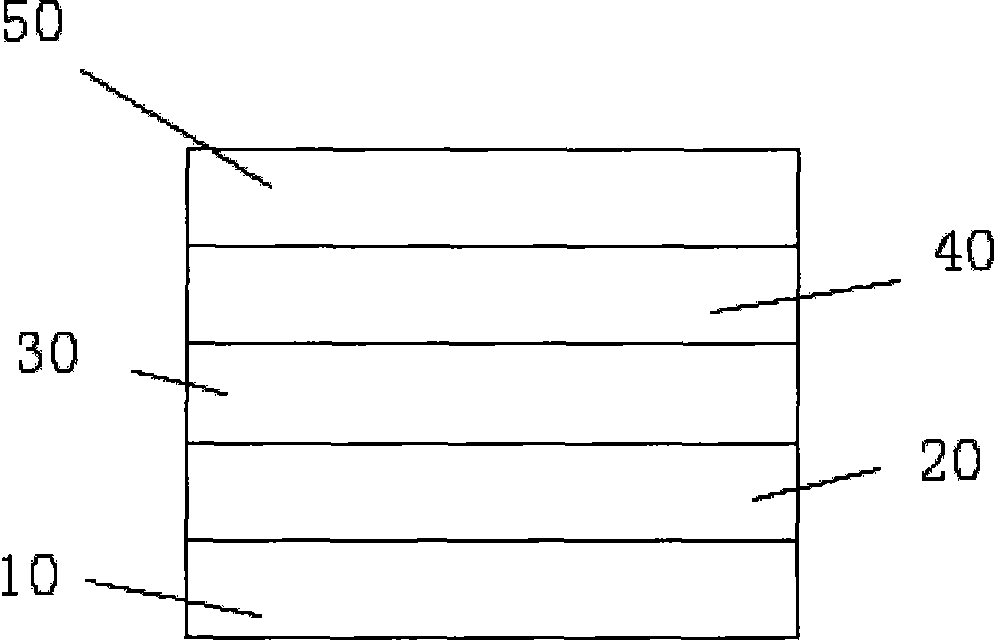

[0036] The original piece of architectural grade transparent float glass with a thickness of 6.0mm is cleaned and dried, and the underlying dielectric layer Si is deposited on the surface in sequence. 3 N 4 / ZnSnO x / ZnO:Al, where Si 3 N 4 The thickness is 10nm, the ratio of argon to nitrogen is 1.2:1, ZnSnO x The thickness is 26nm, the ratio of argon to oxygen is 1:3, the thickness of ZnO:Al is 8nm, and the ratio of argon to oxygen is 1:3; the thickness of the Ag layer of the infrared reflection layer is 10nm, Ar=500sccm; the thickness of the NiCr layer of the metal barrier layer is 3nm, Ar=500sccm ; Upper dielectric layer ZnSnSbO x / Si 3 N 4 , where ZnSnSbO x The thickness is 20nm, the ratio of argon to oxygen is 1:3, Si 3 N 4 The thickness is 15nm, and the ratio of argon to nitrogen is 1.2:1. The above dielectric layers are all deposited by intermediate frequency power supply plus rotary cathode sputtering, and the infrared reflection layer and metal barrier layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com