Method for soft reduction through bulging

A light reduction and bulging technology, which is applied in the field of continuous casting of iron and steel, can solve the problems of heavy maintenance workload, billet quality problems, large reduction pressure, etc., and achieve the effect of improving operation rate, improving reliability and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

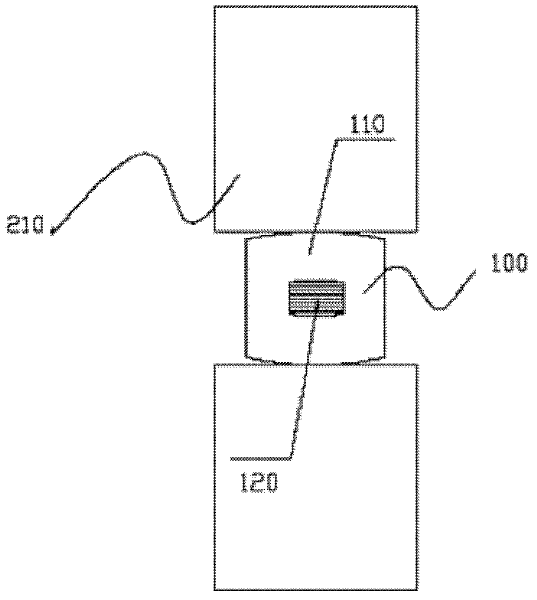

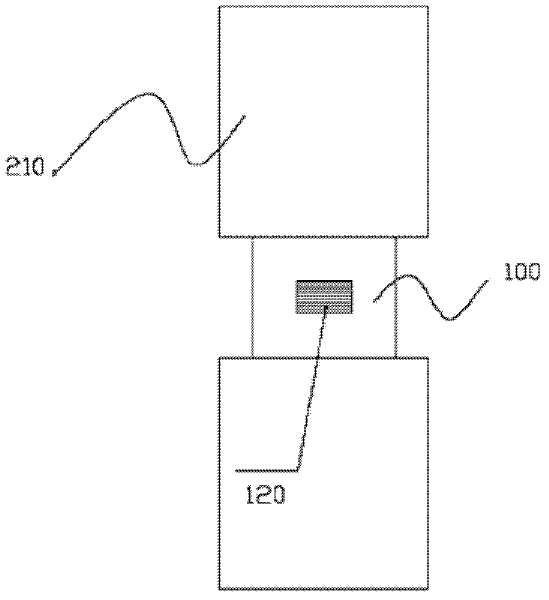

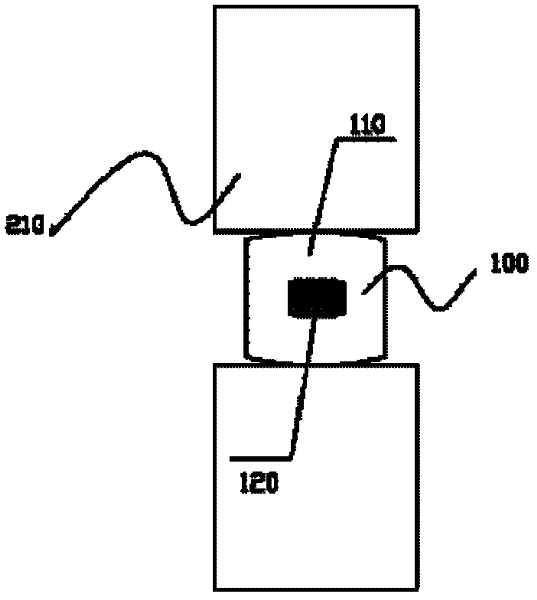

[0021] Such as figure 1 and figure 2 As shown, a method of using bulging for light reduction according to the present invention is suitable for the end of the solidification stage of the slab. The method first selects the bulging 110 with a relatively complete surface of the slab 100, and then controls the tension leveler The upper roll 210 of the upper roller 210 gives a certain amount of reduction to the belly 110, so that the molten steel in the dense paste area 120 inside the cast strand 110 is reasonably distributed in a certain space. The bulging 110 is a defect-free arc-shaped slab with a high middle and low surroundings, thereby reducing the severity of segregation while eliminating the bulging, reducing porosity and shrinkage cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com