Nano-composite pour point depressant compound and preparation method thereof

A nano-composite, pour point depressant technology, used in fuel additives, petroleum industry, liquid carbon-containing fuels, etc., can solve problems such as changing flow properties, reducing diesel cold filter points, etc., to improve low-temperature fluidity and excellent pour point depressant effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

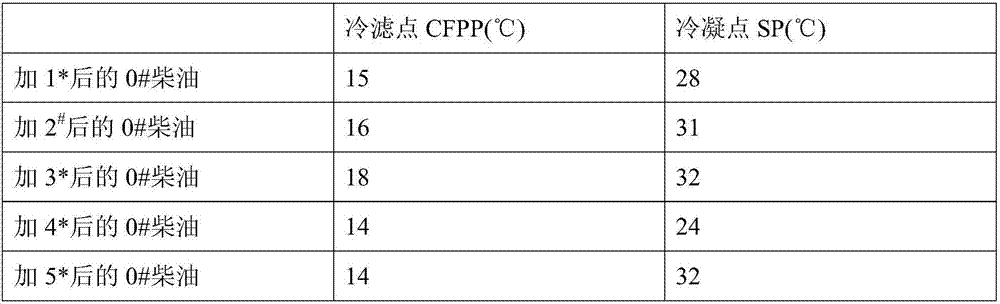

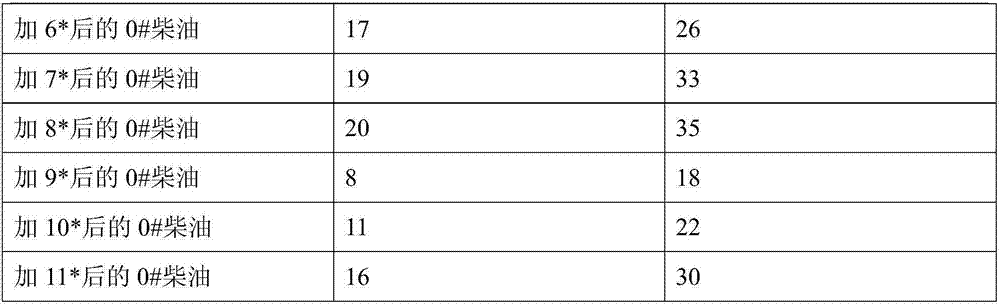

Examples

Embodiment 1

[0023] A nanocomposite pour point depressant composition, which is prepared by a method comprising the following steps:

[0024] The composition is formed by mixing a nanocomposite fumaric acid high-carbon mixed alcohol ester pour point depressant and a nanocomposite fumaric acid high-carbon mixed alcohol ester-maleic anhydride binary copolymer with a mass ratio of 1:1; The nano material and the pour point depressant are used as raw materials, and are prepared by a solvent blending method; wherein: when the solvent is blended, the temperature is 120° C., the solvent used is toluene, and the compound reaction is obtained; the nano material is montmorillonite; the The mass ratio of nanomaterials, mixed alcohol ester pour point depressant and dimer compound in nanocomposite raw materials is 1:1;

[0025] Described high-carbon mixed alcohol fumaric acid ester and high-carbon mixed alcohol fumaric acid ester-maleic anhydride binary copolymer are prepared through the following steps...

Embodiment 2

[0033] The difference from Example 1 is that the high-carbon mixed alcohol used in the preparation step (1) is weighed according to the following ratio (tetradecyl alcohol, cetyl alcohol, stearyl alcohol, eicosanol and behenyl alcohol, which The molar ratio is 1:2:2:2.5:2.5);

[0034] The nanomaterial used in nanocomposite is silicon dioxide;

[0035] Others are the same as in Example 1.

Embodiment 3

[0040] The difference from Example 1 is that the high-carbon mixed alcohol used in the preparation step (1) is weighed according to the following ratio (tetradecyl alcohol, cetyl alcohol, stearyl alcohol, eicosanol and behenyl alcohol, which The molar ratio is 1:3:3:4:4);

[0041] The nanomaterial used in nanocomposite is titanium dioxide;

[0042] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com