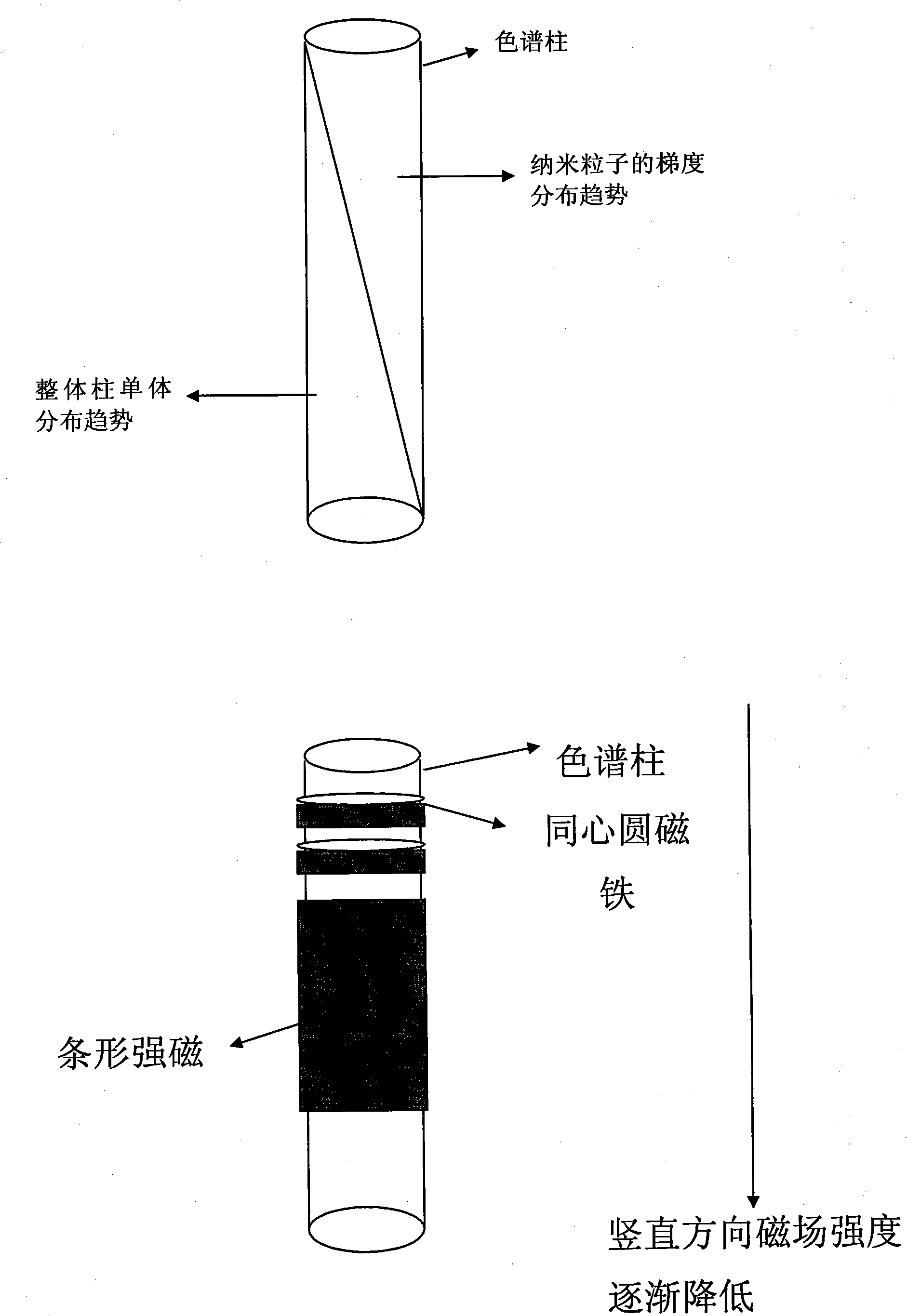

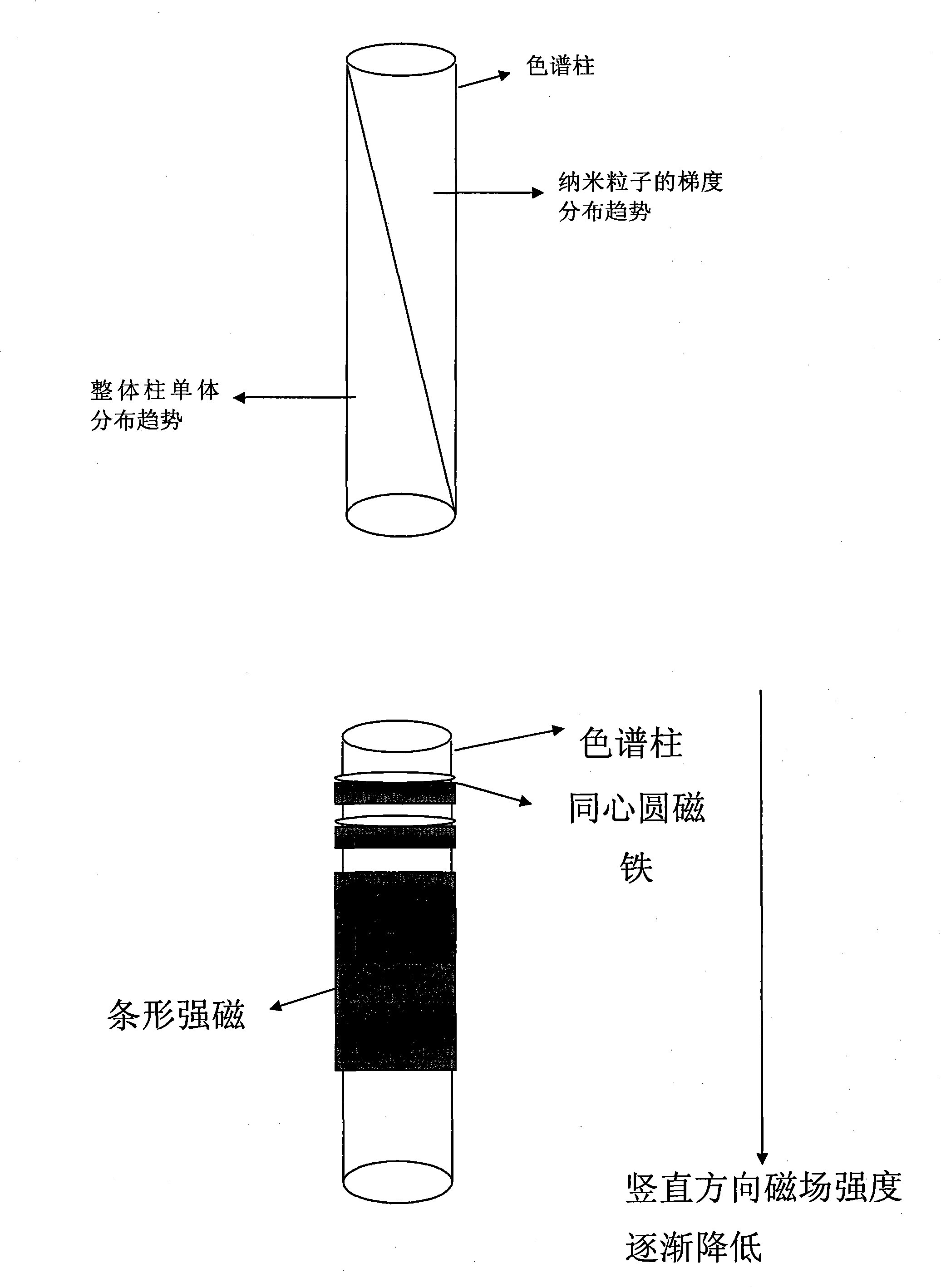

Novel preparation method of monolithic column stationary phase having gradient distribution

A gradient distribution and monolithic column technology, applied in the field of chromatographic stationary phase, can solve problems such as easy generation of bubbles, cumbersome operation, gradient elution obstruction, etc., and achieve high column efficiency and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Weigh 0.1200g of EDMA, 0.1800g of BMA, 0.2880g of n-propanol, 0.1620g of 1,4-butanediol, and 0.0023g of AIBN into a 1.5mL centrifuge tube. Blow with nitrogen until the hot initiator dissolves. Weigh 0.0025g of magnetic nanoparticles into a 1.5mL centrifuge tube, measure 250uL of the above-mentioned BMA matrix into the magnetic nanomaterial, vortex for 1min to mix evenly, and then sonicate for 1min to prevent the magnetic nanoparticles from agglomerating. Extract to 15cm in the capillary, stand vertically for 3 hours, put it in an oven at 60°C for 22 hours (keep standing vertically), rinse the reacted capillary column with methanol first, and then rinse with water to wash away unreacted The residue is then equilibrated with the mobile phase for a period of time.

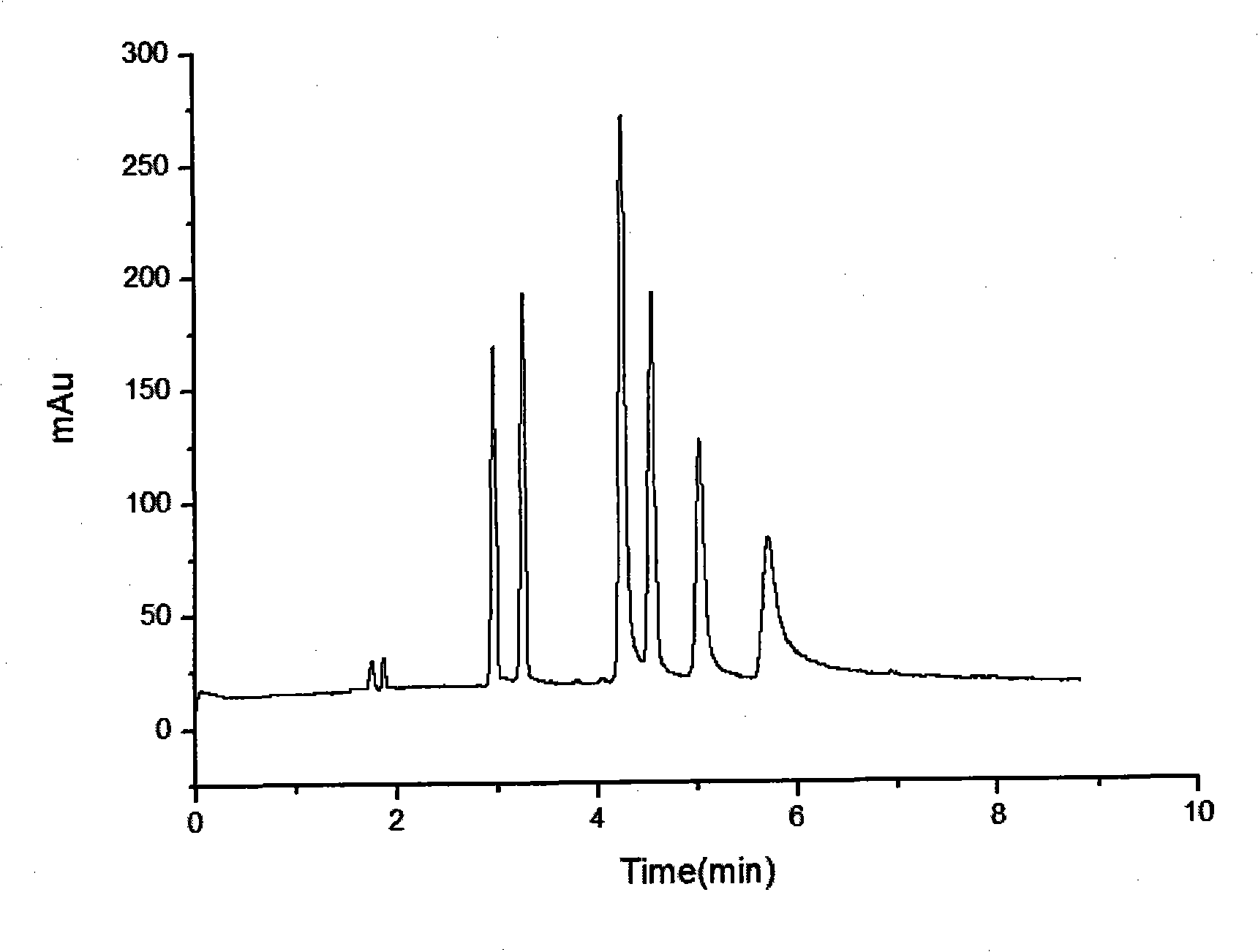

[0048]The invention realizes the gradient separation directly using the stationary phase without adjusting the mobile phase, and is especially suitable for the separation of complex samples. The system not on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com