Preparation method and product of minimal acid water soluble ginkgo leaf extract

A technology of ginkgo biloba leaves and extract, applied in the field of traditional Chinese medicine extraction, can solve the problems of high ginkgolic acid content, poor water solubility, etc., and achieve the effects of less production input, stable product quality, and strong production operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

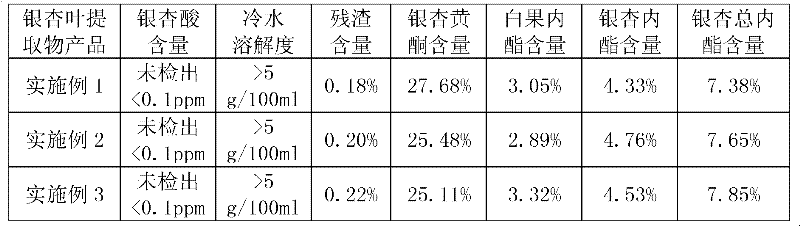

[0022] Embodiment 1 of the present invention: get the dry ginkgo leaf 400kg that sells in Pizhou City, Jiangsu Province, drop into 6 tons of extraction ponds, add 4 tons of deionized water and soak for 1 hour, heat and boil to extract for 2 hours, drain the extract; Ginkgo leaf residue Add an equal amount of water to repeat the extraction once, the water extracts are combined and concentrated to 1 ton, put into a 2 ton storage tank and let stand for cooling for 15 hours, take the upper layer solution and add 10% chitin solution to flocculate to form a precipitate, filter with diatomaceous earth to remove the precipitate, The filtered supernatant was put on an AB-8 macroporous resin column, washed with 1.2 tons of deionized water to remove polar impurities, eluted with 2.4 tons of 40%-50% ethanol solvent, concentrated to no ethanol, and refrigerated at low temperature (1°C) for 15 Hours until the feed liquid temperature is 5°C. Take the supernatant and filter it with diatomaceo...

Embodiment 2

[0023] Embodiment 2 of the present invention: get the drying ginkgo leaf 500kg that sells in Pizhou City, Jiangsu Province, drop into 6 tons of extraction ponds, add 5 tons of deionized water and soak for 1 hour, heat and boil and extract for 2 hours, drain the extract; Ginkgo leaf residue Add water and repeat the extraction once, the water extracts are combined and concentrated to 1 / 5 of the original volume, put into a 2-ton storage tank and let stand for cooling for 13 hours, take the upper layer solution and add 10% gelatin solution to flocculate to form a precipitate, filter with diatomaceous earth to remove the precipitate, Filter the clear liquid onto a DM130 macroporous resin column, wash away polar impurities with 1.5 tons of deionized water, elute with 2.5 tons of 40% to 50% ethanol solvent, concentrate the eluent to no ethanol, and refrigerate at low temperature (0°C to 1°C) 13 hours until the feed liquid temperature is 3°C. The supernatant was filtered with diatomac...

Embodiment 3

[0024]Embodiment 3: Get 300kg of dry ginkgo leaves, drop into the extraction pool, add 3 tons of deionized water, heat and boil for extraction for 2 hours, and drain the extract; add water to the ginkgo leaf residue and repeat the extraction once, and the water extracts are combined and concentrated to 1% of the original volume. / 4, put it in the storage tank and let it stand for cooling for 18 hours, take the upper layer solution and add 10% chitosan solution for flocculation and precipitation, filter the precipitation, put the supernatant on the D101 macroporous resin column, and use 2 times the column volume of deionized Wash with water to remove polar impurities, elute with 40% to 50% ethanol solvent of 5 times the column volume, concentrate the eluate to remove ethanol, and refrigerate at low temperature (0°C to 1°C) for 18 hours until the temperature of the feed liquid is 4°C. The supernatant was filtered with diatomaceous earth, the filtrate was concentrated in vacuo to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com