Microwave-hydrolyzation method of pearl powder

A pearl powder and microwave technology, which is used in pharmaceutical formulations, food preparation, food science and other directions, can solve the problems of inability to accurately control the temperature of microwave ovens and cannot provide them, and achieve the effects of high utilization rate, improved reaction rate, and simple post-processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

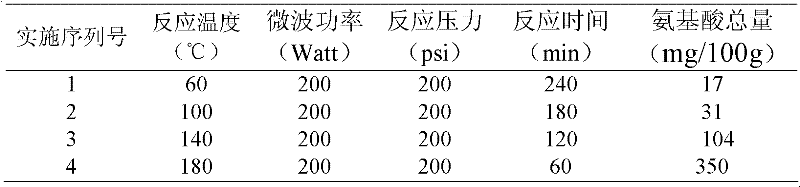

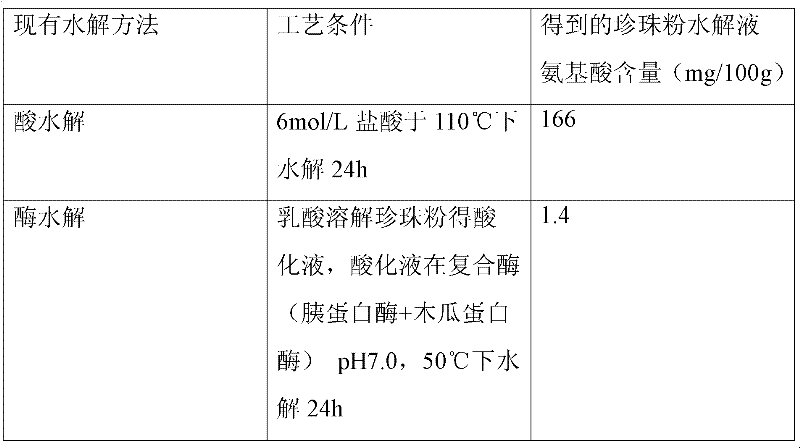

Examples

Embodiment 1

[0022] 1) Place 2 g of pearl powder and 10 g of pure water A obtained from the commercially available (Zhejiang Osman Group Deqing Biotechnology Co., Ltd.) Microwave power 200W, reaction time 1h, obtain reaction solution A; 2) add 10g pure water B to step 1) reaction solution A, obtain reaction solution B, the total amount of water A and water B added is 10 times of the pearl powder feeding amount, Keep the temperature of the system at 60°C and react for 3 hours with intermittent gradient heating, that is, react at 60°C for 30 minutes, stop for 10 minutes, react for another 30 minutes, stop for 15 minutes, react for another 30 minutes, stop for 20 minutes, react for another 30 minutes, stop for 25 minutes, and then react for 30 minutes , stop for 30 minutes, react for another 30 minutes, and the reaction ends.

[0023] Reacted for 3h, after the reaction was finished, the reactor was cooled, the reaction liquid B was filtered, and the filter cake was vacuum-dried to constant we...

Embodiment 2

[0028] Reaction condition is set as step 1) temperature 100 ℃, pressure 200Pa, microwave power 200W, reaction time is 180min, experiment method and sampling amount of pearl powder are the same as embodiment 1, experiment result is shown in table 1.

Embodiment 3

[0030] The reaction conditions are set as step 1) temperature 140°C, pressure 200Pa, microwave power 200W, and reaction time 120min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com