Neural network inverse-based soft sensing method for compensation capacity and medium loss of capacitor and on-line monitoring

A neural network inverse and neural network technology, applied in the field of intelligent capacitor online monitoring system of distribution network, can solve the problems of no patents and documents, etc., achieve the effect of easy engineering implementation and overcome strong dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

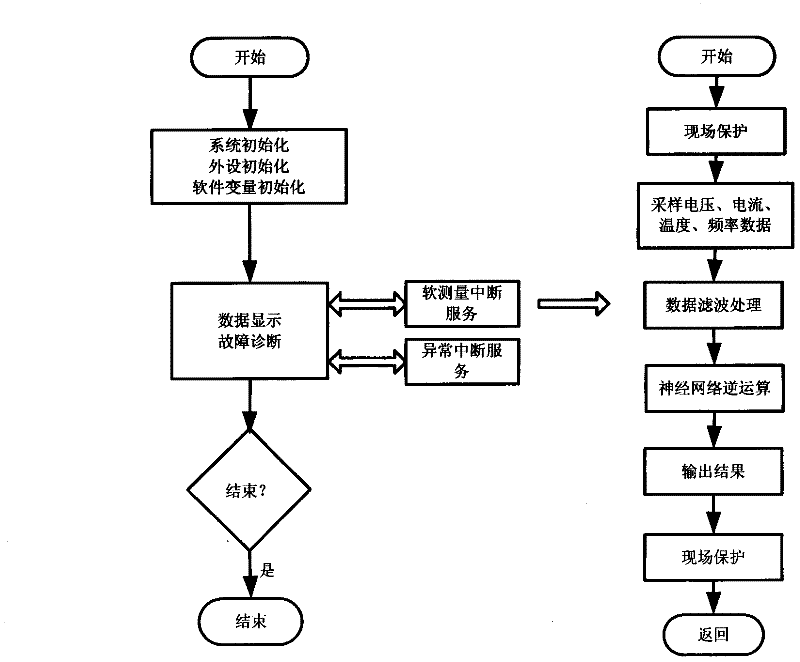

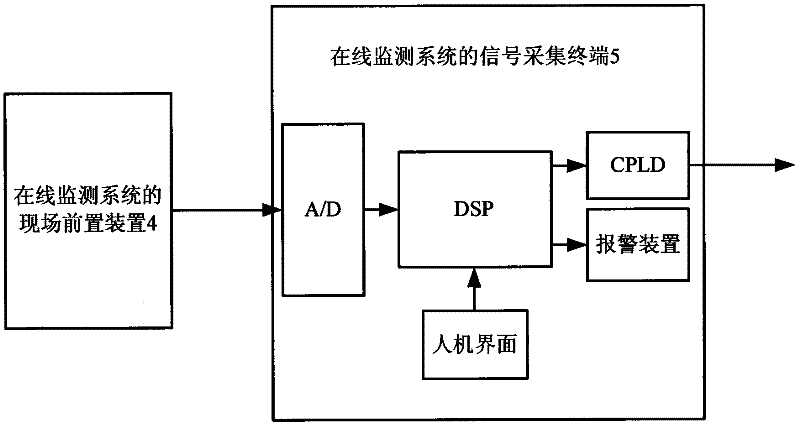

[0035] specific implementation plan

[0036] The specific implementation scheme of the neural network inverse soft measuring method and on-line monitoring system of distribution network intelligent capacitor parameter of the present invention is:

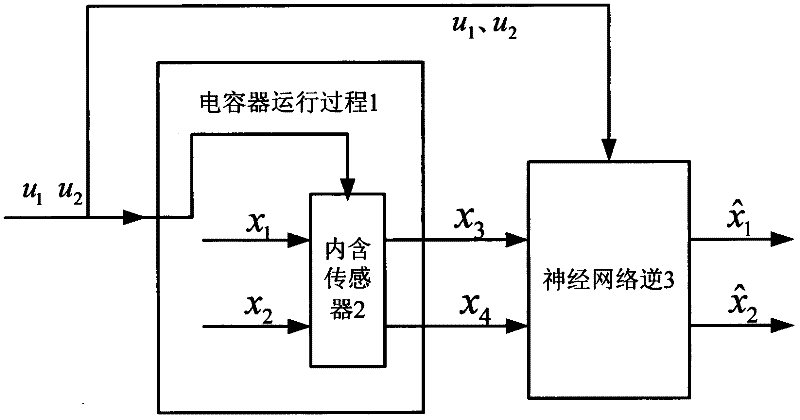

[0037] 1. Specifically determine the input directly measurable online, the output directly measurable online and the non-directly measurable offline analysis in the capacitor operation process 1. According to the model of the operation process of the capacitor:

[0038]

[0039] Here the state dimension is 4, and the input dimension is 2, namely: x=(x 1 , x 2 , x 3 , x 4 ) T , u=(u 1 , u 2 ) T , where the operating current u of the capacitor 1 , capacitor temperature u 2 , Capacitor compensation capacity x 1 , Capacitor dielectric loss x 2 , The operating voltage of the capacitor x 3 , grid frequency x 4 ; is the derivative of capacitor compensation capacity, is the derivative of the dielectric loss of the capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com