Process for continuously and rapidly determining components in desulfurization gypsum

A desulfurization gypsum, rapid determination technology, applied in the field of chemical detection, can solve the problems of analysis error, high sampling frequency, complicated operation process, etc., and achieve the effect of reducing operation intensity, reducing analysis error, and high sampling representativeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

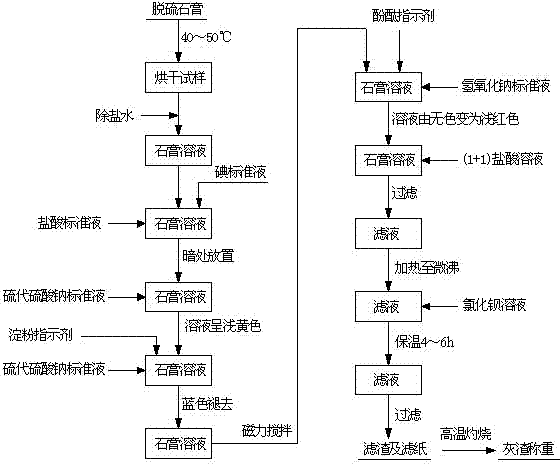

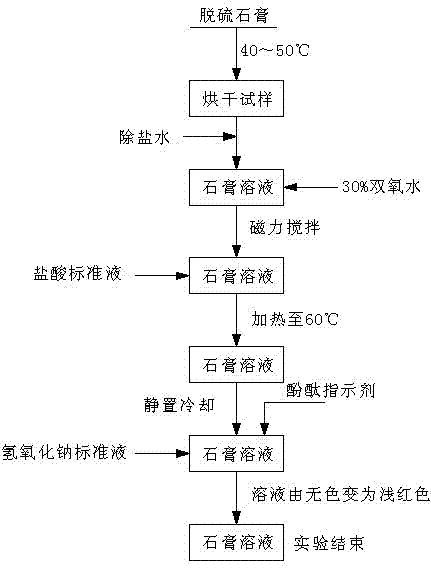

Method used

Image

Examples

Embodiment 1

[0037] Put the desulfurized gypsum sample (referred to as 1#) taken from the M power plant into an oven, bake at 45°C for 4 hours, and place the dried sample in a mortar to grind and mix well. Weigh 1.0g (accurate to 0.0001g) of the dried sample, put it into a 250mL conical flask, dissolve and dilute it with 100mL desalted water, add 30mL0.1mol / L hydrochloric acid standard solution, 10ml0.05mol / L iodine standard solution, Shake well, place in dark place for 5min, titrate with 0.1mol / L sodium thiosulfate standard solution to light yellow, add 3-5 drops of starch indicator, continue to titrate with 0.1mol / L sodium thiosulfate standard solution to blue The end point is when the color just fades away, and the volume of sodium thiosulfate standard solution consumed is recorded, and a blank test is carried out at the same time. Place the solution after the determination of calcium sulfite on a magnetic stirrer and stir for 10 minutes, add 5-8 drops of phenolphthalein indicator, and ...

Embodiment 2

[0039]Put the desulfurized gypsum sample (denoted as 2#) taken from the P power plant into an oven, bake at 45°C for 4 hours, and place the obtained dried sample in a mortar to grind and mix well. Weigh 1.5g (accurate to 0.0001g) dried sample, put it into a 250mL conical flask, dissolve and dilute it with 100mL desalted water, add 40mL0.1mol / L hydrochloric acid standard solution, 10ml0.05mol / L iodine standard solution, Shake well, place in dark place for 5min, titrate with 0.1mol / L sodium thiosulfate standard solution to light yellow, add 3-5 drops of starch indicator, continue to titrate with 0.1mol / L sodium thiosulfate standard solution to blue The end point is when the color just fades away, and the volume of sodium thiosulfate standard solution consumed is recorded, and a blank test is carried out at the same time. Place the solution after the determination of calcium sulfite on a magnetic stirrer and stir for 10 minutes, add 5-8 drops of phenolphthalein indicator, and tit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com