Backlight module

A technology of backlight module and light, which is applied in the direction of electric light source, light source fixing, lighting device, etc., can solve the problems of complex overall structure, increased difficulty of assembly, increased cost, etc., and achieve high light extraction efficiency, low manufacturing cost, and high structural strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

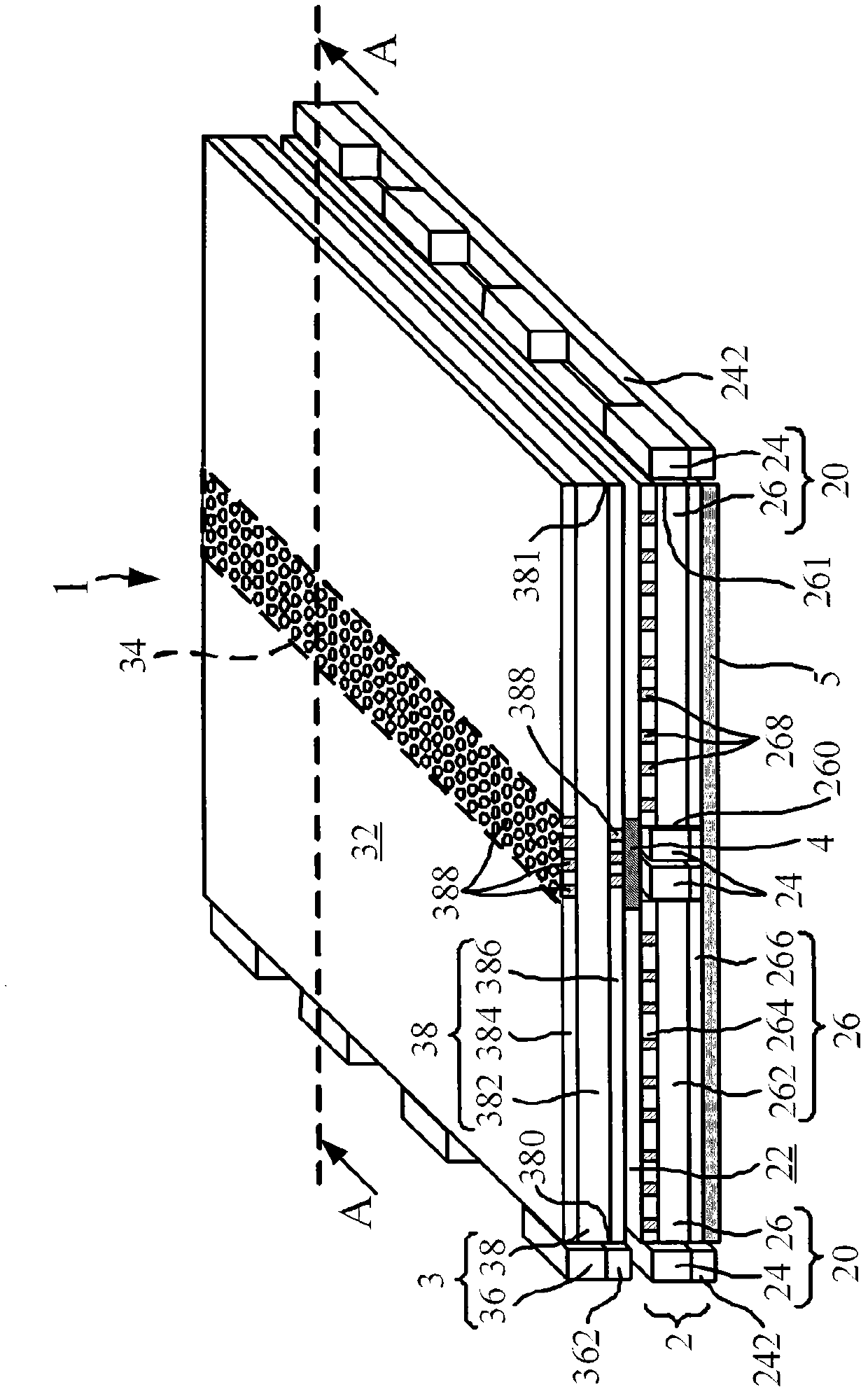

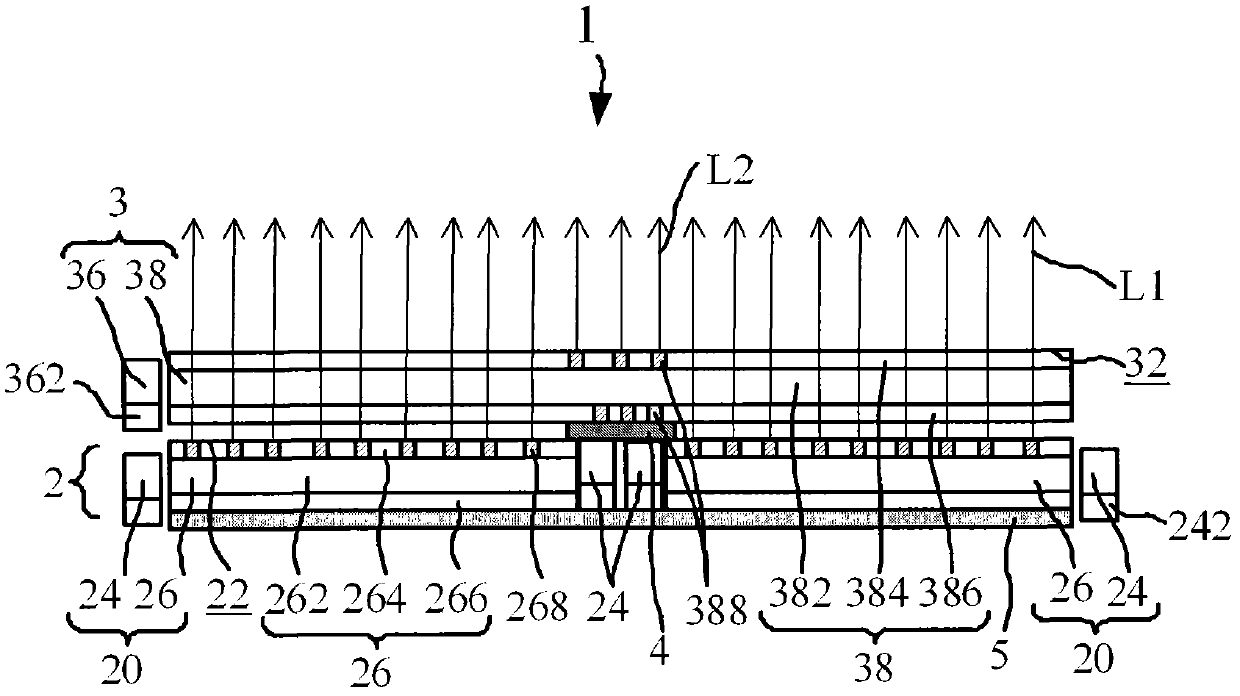

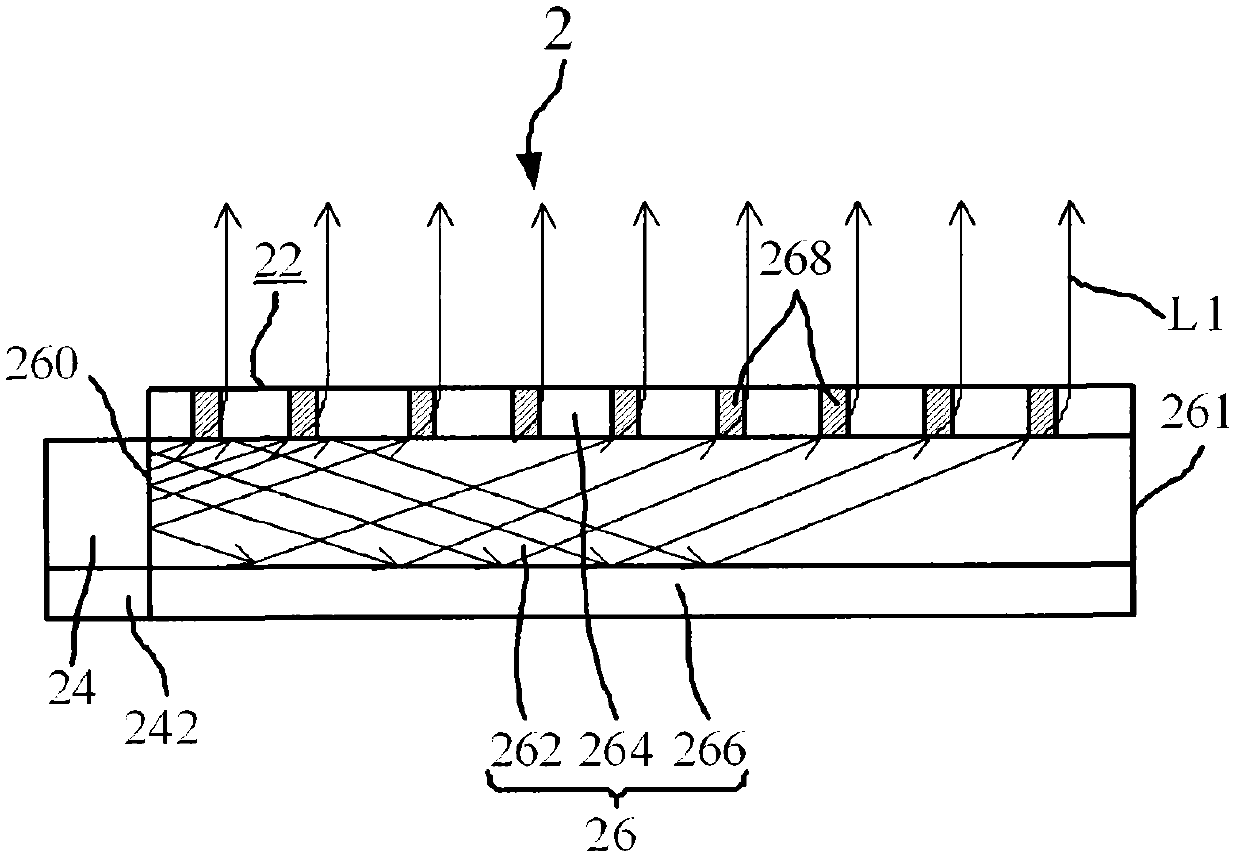

[0039] The present invention provides a backlight module, and in particular, the backlight module according to the present invention has a double-layer light source structure. Moreover, the backlight module according to the present invention can meet the requirements of high light extraction efficiency, high luminance, high uniformity, high structural strength, and simplified structure, and has the advantages of low manufacturing cost and easy design for liquid crystal panels of different sizes. Moreover, the backlight module according to the present invention does not need a heavy light box, so that the whole backlight module is quite light and thin. Specific embodiments of the present invention will be described in detail below, so as to fully illustrate the features, spirit, advantages and practicability of the present invention.

[0040] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the structure of the backlight module 1 according to a preferred em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com