Acid-proof X70MS steel-grade spiral welded pipe and manufacturing method thereof

A technology of spiral welded pipe and manufacturing method, which is applied in the field of acid-resistant X70MS steel grade spiral welded pipe and its manufacturing field, can solve problems such as pipeline failure, hydrogen sulfide acid corrosion, etc., and achieve improved accuracy and reliability, strong practicability, and strengthened welding The effect of process parameter control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

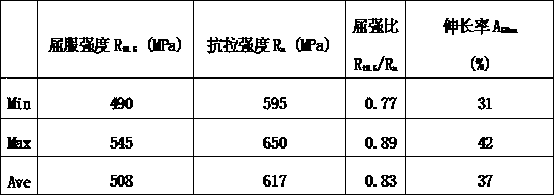

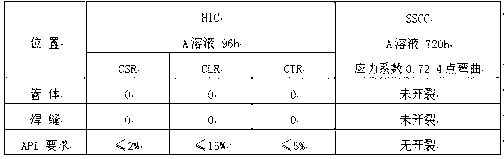

[0030] The chemical composition of the coil used in the acid-resistant X70MS steel grade spiral welded pipe in this example is shown in Table 1, and the mechanical properties are shown in Table 2. The thickness of the steel plate is 13.7mm, and the outer diameter of the steel pipe is F914mm. The manufacturing process steps of the acid-resistant X70MS steel grade spiral welded pipe are as follows:

[0031] 1. The coil is uncoiled and leveled;

[0032] 2. Edge milling: rough milling first, and milling off the width of the plate edge by 10-20mm to ensure the removal of plate edge defects and crescent bends caused by the steel billet and rolling process; then finish milling the X-shaped groove, that is, to The two butt plate edges are grooved with a blunt edge size of 7.5mm and a groove angle of 35°, and an X-shaped groove of 70° is formed after the two sides of the steel plate are butted;

[0033] 3. Pre-bending: Pre-bend the delivery side and free side of the coiled plate on th...

Embodiment 2

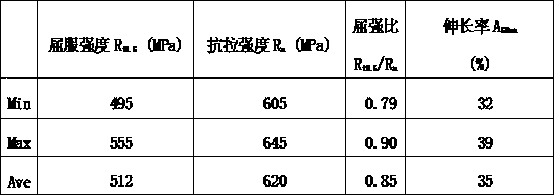

[0059] The chemical composition of the coil used in the acid-resistant X70MS steel grade spiral welded pipe in this example is shown in Table 8, and the mechanical properties are shown in Table 9. The thickness of the steel plate is 13.7mm, and the outer diameter of the steel pipe is F914mm. The manufacturing process steps of the acid-resistant X70MS steel grade spiral welded pipe are as follows:

[0060] 1. The coil is uncoiled and leveled;

[0061] 2. Edge milling: rough milling first, and milling off the width of the plate edge by 10-20mm to ensure the removal of plate edge defects and crescent bends caused by the steel billet and rolling process; then finish milling the X-shaped groove, that is, to The two butt plate edges are grooved with a blunt edge size of 7.0mm and a groove angle of 30°, and a 60° X-shaped groove is formed after the two sides of the steel plate are butted;

[0062] 3. Pre-bending: Pre-bend the delivery side and free side of the coiled plate on the tw...

Embodiment 3

[0088] The chemical composition of the coil used in the acid-resistant X70MS steel grade spiral welded pipe in this example is shown in Table 15, and the mechanical properties are shown in Table 16. The thickness of the steel plate is 13.7mm, and the outer diameter of the steel pipe is F914mm. The manufacturing process steps of the acid-resistant X70MS steel grade spiral welded pipe are as follows:

[0089] 1. The coil is uncoiled and leveled;

[0090] 2. Edge milling: rough milling first, and milling off the width of the plate edge by 10-20mm to ensure the removal of plate edge defects and crescent bends caused by the steel billet and rolling process; then finish milling the X-shaped groove, that is, to The two butt plate edges are respectively made with a groove with a blunt edge size of 8mm and a groove angle of 40°, and an 80° X-shaped groove is formed after the two sides of the steel plate are butted;

[0091] 3. Pre-bending: Pre-bend the delivery side and free side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com