Method for producing grease rich in essential fatty acid linoleic acid and alpha-linolenic acid through culturing microalgae by use of CO2

A fatty acid linoleic acid, CO2 technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of food crisis, slow growth, low long-term benefits, etc., achieve high oil yield, alleviate greenhouse effect, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Construction of specific screening culture system: buy 250L light incubator, 6 air flow meters, 6 CO 2 flow meter, CO 2 Gas meter, air pump, CO 2 A steel cylinder, a vent tube, a filter membrane, a special gas distribution bracket, and a special vent culture bottle are assembled to form a set that can provide 6 different CO2 at the same time. 2 Concentration of algae screening culture and domestication device.

[0037] (2) Preparation of specific medium: since it is mainly CO 2 Crop carbon source, in order to acclimatize microalgae to CO 2 The preference of the specific medium we configured is mainly to remove the carbon source Na 2 CO 3 BG11 medium. And according to 1mg Na per liter 2 MGEDTA, 36mg CaCl 2 2H 2 O, 75mg MgSO 4 ·7H 2 O, 40 mg K 2 HPO 4 ·3H 2 O, 2.86 mg H 3 BO 3 , 1.81mg MnCl 2 4H 2 O, 0.222mg ZnSO 4 ·7H 2 O, 0.079mg CuSO 4 ·5H 2 O, 0.05mg CoCl 2 ·6H 2 O, 0.391 mg NaMoO 4 2H 2 O and 1500mg NaNO 3 The amount of . to configure a...

Embodiment 2-6

[0042] Test with the similar method of example 1, pass into CO except that the Scenedesmus obliquus after cultivating acclimatization 2 The concentrations were 0.03%, 5%, 10%, 20%, 30%, and 50%, respectively, and other parameters remained unchanged.

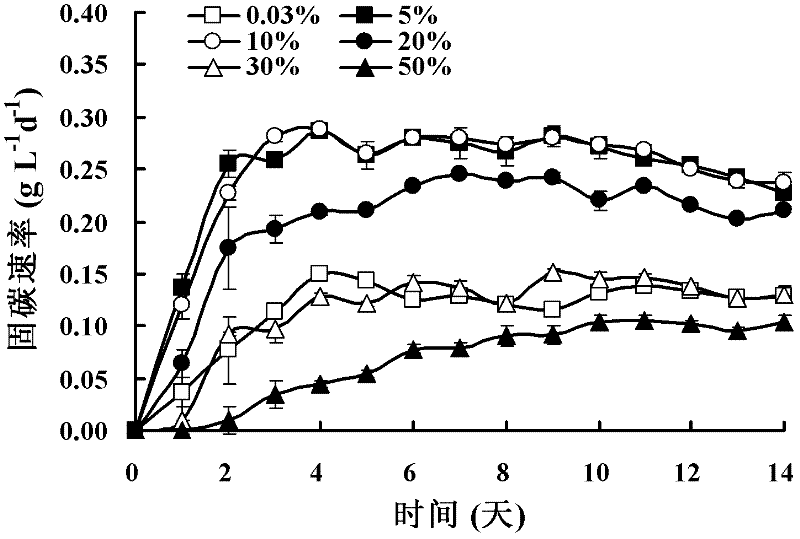

[0043] figure 1 Indicated at 5% and 10% concentrations of CO 2 Scenedesmus obliquus had the largest biomass. figure 2 Indicated at 5% and 10% concentrations of CO 2Scenedesmus obliquus for CO 2 the maximum rate of carbon fixation. image 3 Indicated at 50% concentration of CO 2 Scenedesmus obliquus had the highest oil content. Figure 4 Indicated at 0.03%, 5%, 10%, 20%, 30%, 50% CO 2 Under the concentration, the contents of linoleic acid are 13%, 20.65%, 19%, 19.14%, 13.43%, 13.34% respectively; and the contents of α-linolenic acid are 43.35%, 40%, 41.54%, 40.67%, 48.44%, 48.23%, so at concentrations above 5% of CO 2 The total content of essential fatty acids linoleic acid and α-linolenic acid in Scenedesmus obliquus is...

Embodiment 7

[0045] Response surface analysis was used to optimize the culture conditions. The response surface analysis experiment mainly used Minitab 15 software, and the central composite design method (the analysis method in the Minitab software) was adopted to carry out the experimental design. Table 1 refers to the factors and level coding values of the response surface experiment. The independent variables are carbon dioxide concentration and light intensity, and the response variable is biomass. The design and results of the central composite experiment are shown in Table 2. The inoculation density is 0.05g / L; the independent variable light intensity range is 2000lux-10000lux; the independent variable carbon dioxide concentration range is 0.03%-40%; the ventilation flow rate is 0.5vvm; the culture temperature is 30±1°C; 0.1. Figure 5 and Figure 6 Respectively, using the response surface carbon dioxide and light intensity to interact to affect the biomass of Scenedesmus obliqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com