C12-C13 long-chain binary acid refining method

A C12-C13, 1.C12-C13 technology, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of difficult process control, environmental pollution, high cost, and achieve easy process control, solvent The effect of easy source and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

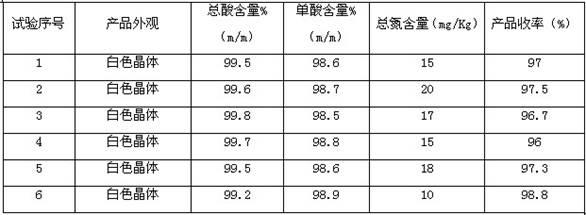

[0015] Example 1: Add 10g of crude dodecanedibasic acid and 1g of activated carbon with an average particle size of 300 mesh into a pressure vessel with a stirring and heating system, add 100ml of pure water into the vessel, turn on the stirring and heating steam, and heat to 140°C. Control the pressure to 0.36Mpa and maintain it for 30min. Use nitrogen to press the solid-liquid mixture in the container into the pressure filter to filter, remove the activated carbon, cool the obtained clear liquid to 80°C and keep it for 2 hours, and then slowly cool down to 20°C. The cooling speed is controlled. Use a centrifuge to dehydrate the wet filter cake at 20°C / hour, rinse the wet filter cake with pure water for 1 minute, and after centrifuging again, put the filter cake in an oven to control the temperature at 100-105°C, and dry it for 2-4 hours to obtain 9.7g di Elemental acid boutique. The analysis results are shown in Table 1.

Embodiment 2

[0016] Example 2 : Add 20g of crude dodecanedibasic acid and 2g of activated carbon with an average particle size of 300 mesh into a pressure vessel with a stirring and heating system, add 100ml of pure water into the vessel, turn on stirring and heating steam, and heat to 170°C , control the pressure at 0.80Mpa and maintain it for 30min, press the solid-liquid mixture in the container into the pressure filter with nitrogen to filter, remove the activated carbon, cool the obtained clear liquid to 80°C and keep it for 2 hours, then slowly cool down to 20°C, the cooling speed Control the temperature at 20°C / hour, centrifuge and dehydrate with a centrifuge, rinse the wet filter cake with pure water for 2 minutes, and after centrifuging again, put the filter cake in an oven to control the temperature at 100-105°C, and dry it for 2-4 hours to obtain 19.5g Dibasic acid boutique. The analysis results are shown in Table 1.

Embodiment 3

[0017] Example 3: Add 30g of crude dodecanedibasic acid and 3g of activated carbon with an average particle size of 300 mesh into a pressure vessel with a stirring and heating system, add 100ml of pure water into the vessel, turn on the stirring and heating steam, and heat to 190°C. Control the pressure at 1.3Mpa and maintain it for 30 minutes, press the solid-liquid mixture in the container into the pressure filter with nitrogen to filter, remove the activated carbon, cool the obtained clear liquid to 80°C and keep it for 2 hours, then slowly cool down to 20°C, the cooling speed is controlled Use a centrifuge to dehydrate the wet filter cake at 20°C / hour, rinse the wet filter cake with pure water for 2 minutes, and after centrifuging again, put the filter cake in an oven to control the temperature at 100-105°C and dry it for 2-4 hours to obtain 29.0 g of Elemental acid boutique. The analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com