Powdery metallurgic product deburring device

A powder metallurgy and deburring technology, which is applied in metal processing equipment, grinding machines, grinding/polishing equipment, etc., can solve the problems of low work efficiency and different degrees of burr removal cleanliness, and achieve simple structure, quality assurance, and work improvement. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

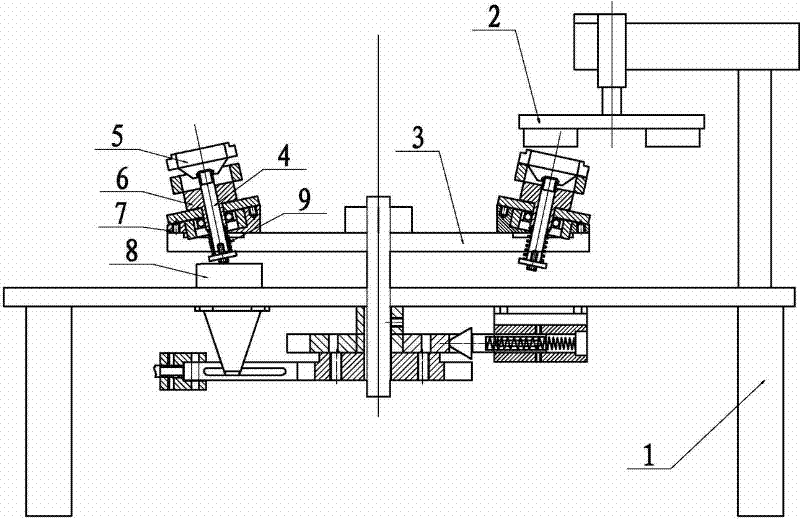

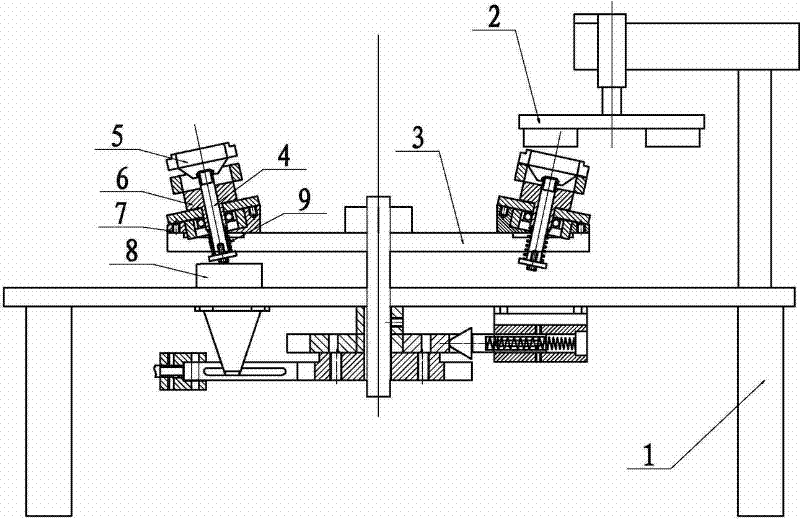

[0013] Depend on figure 1 It can be seen that a deburring device for powder metallurgy products includes a frame 1, which is characterized in that the frame 1 is provided with a rotating disc 3 driven by power, and the rotating disc 3 is evenly distributed along the circumferential direction with workpiece clamping and positioning mechanism, the frame 1 is also provided with a rotating wire brush 2 driven by a motor, and the rotating wire brush 2 is installed above the workpiece clamping and positioning mechanism to form a working station.

[0014] The workpiece clamping and positioning mechanism of the present invention includes a base 6 installed on the rotating disk 3, and the base 6 is provided with a clamp 5 for clamping the workpiece.

[0015] The fixture 5 of the present invention is installed on the base 6 through the push rod 4 , and the frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com