Laser welding fixture for square battery module

A laser welding jig and battery module technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of high heat generation, low efficiency, poor batch stability, etc., and achieve high welding success rate and easy operation quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

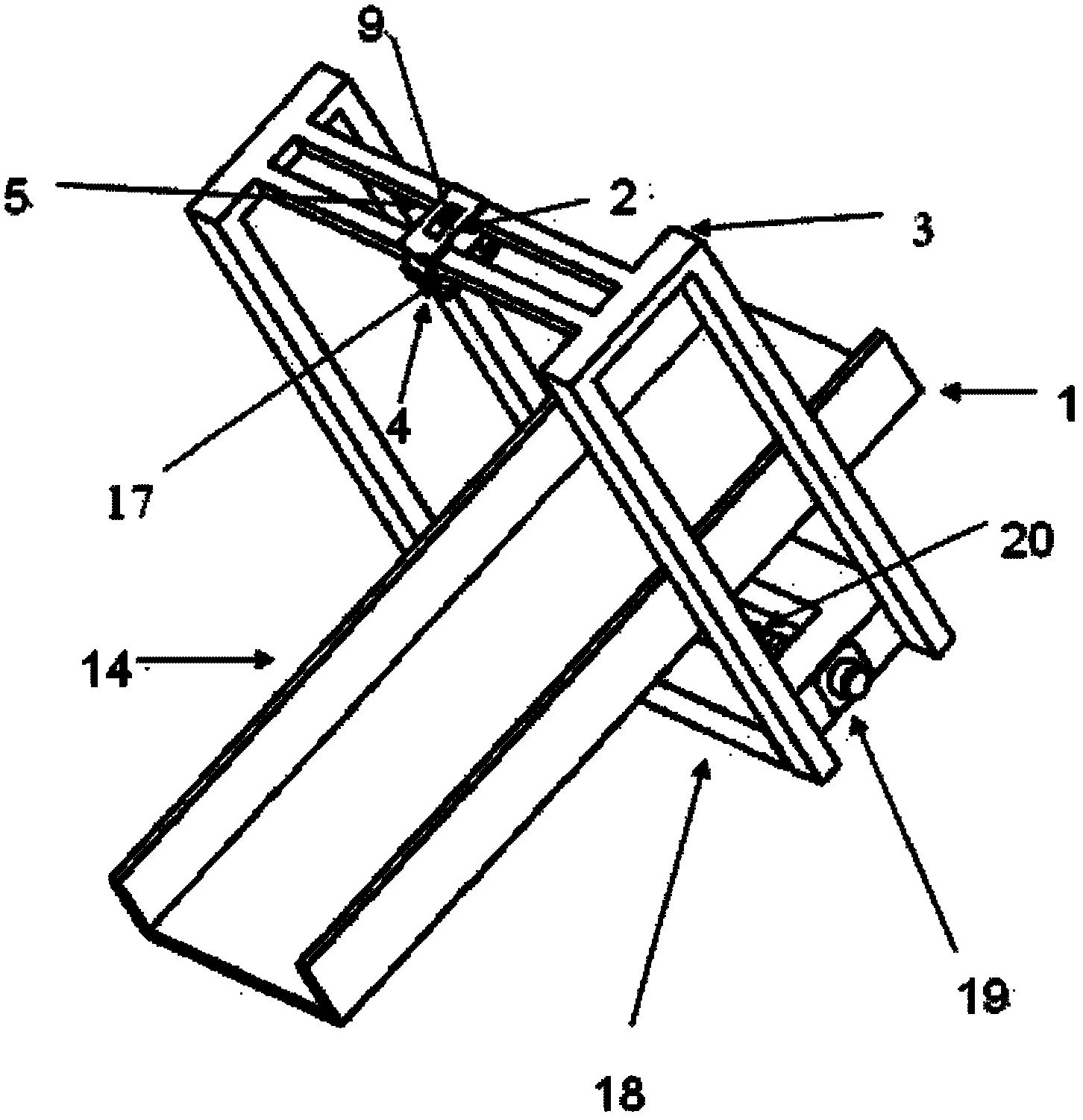

[0020] see figure 1 , is a preferred embodiment of the present invention, suitable for fiber output lasers. The fixture for welding the battery pack and the connecting piece mainly includes a workbench 1, a pressing mechanism 2 and an "H" type gantry support structure 3.

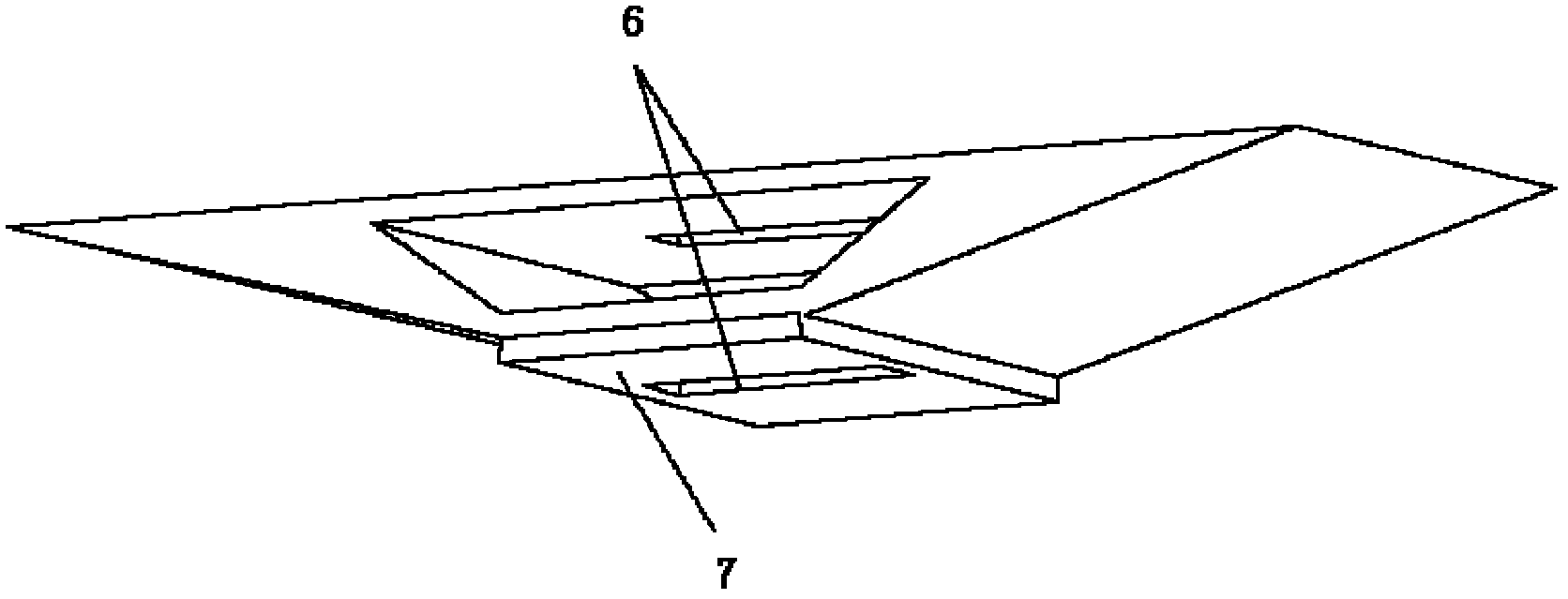

[0021] The pressing mechanism is fixed on the "H" type gantry support structure 3, which includes a pressing frame 4 and a cylinder driving device 5. The hold-down frame 4 is a steel structure with slits 6 (see figure 2 ). Both ends of the pressing frame 4 are respectively connected with the piston rod 17 of the cylinder driving device 5 . The bottom surface of the compression frame 4 has a rubber block 7 containing a slit 6 (see figure 2 ).

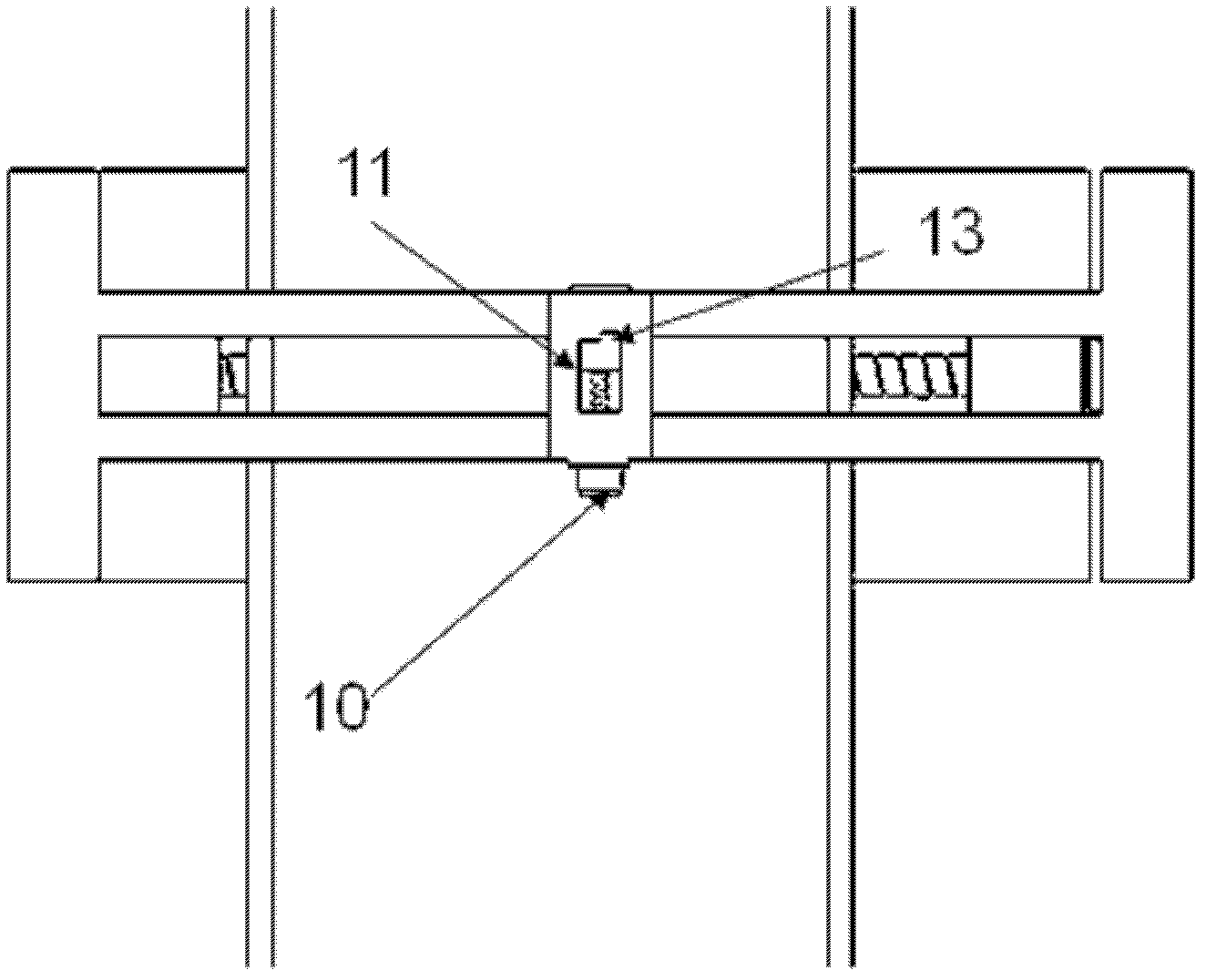

[0022] The "H" type gantry support frame 3 is fixed on both sides of the workbench 1, and it includes an "H" type gantry support frame 8 and a laser head driving device 9, and the driving device 9 is composed of a driving motor 10 and a screw rod 1...

Embodiment 2

[0027] see Figure 5-7 , this embodiment is applicable to a fixed optical path output laser. The fixture for welding the battery pack and the connecting piece mainly includes a workbench 1, a pressing mechanism 2 and an "H" type gantry support structure 3.

[0028] The pressing mechanism is fixed on the “H” type gantry support structure 3 , which includes a pressing frame 30 (see FIG. 6 ) and a cylinder driving device 5 . The pressing frame 30 is a steel structure with a slit 6 . Both ends of the pressing frame 30 are respectively connected with the piston rod 17 of the cylinder driving device 5 . A rubber block 7 containing a slit 6 is arranged on the bottom surface of the pressing frame 30 .

[0029] The "H" type gantry support frame is fixed on both sides of the workbench 1, and it includes an "H" type gantry support frame 21 and a pressing mechanism slide rail 22. A limit block 23 is fixed on the "H" type gantry support frame 21, which is used to limit the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com