Four-electrode welding device for fiber splicer

A technology of optical fiber fusion splicing machine and welding device, which is applied in the direction of light guides, optics, optical components, etc., and can solve problems such as uneven heating of optical fibers and failure of fusion splicing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

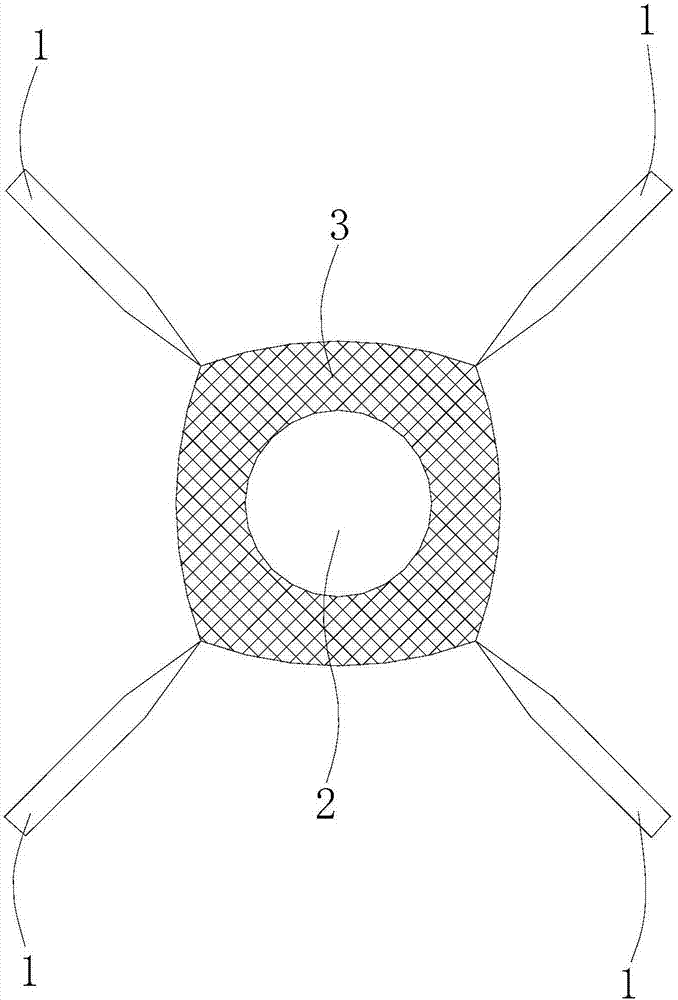

[0014] Such as image 3 shown

[0015] The electrode welding device includes four electrode rods 1, the four electrode rods 1 are arranged in a square, the center lines of the four electrode rods 1 are all in the same vertical plane, and the extension lines of the center lines of the four electrode rods 1 intersect at one point, each The tips of each electrode rod 1 point to this intersection point, the outer diameter of each electrode rod 1 is 2 mm, and the minimum distance between any two electrode rods 1 is 4 mm.

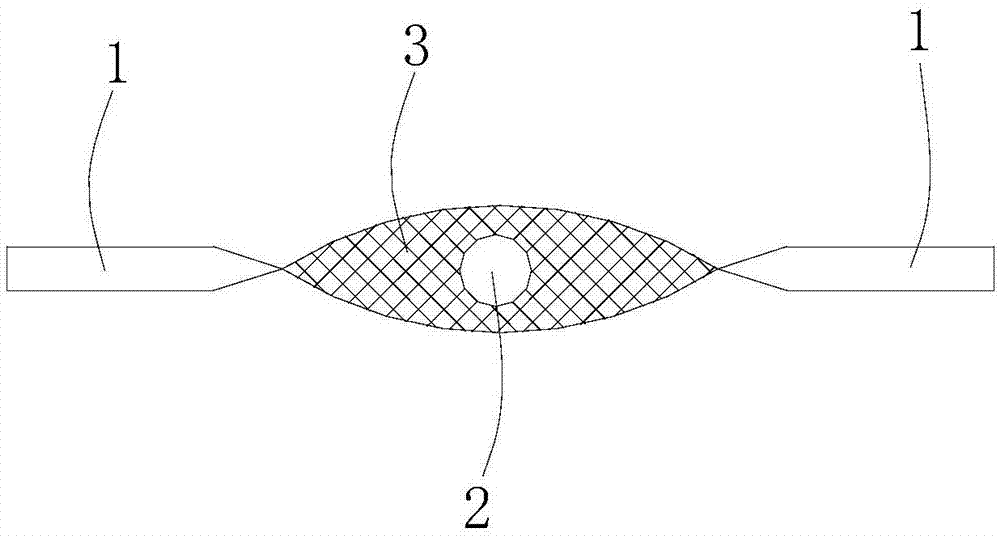

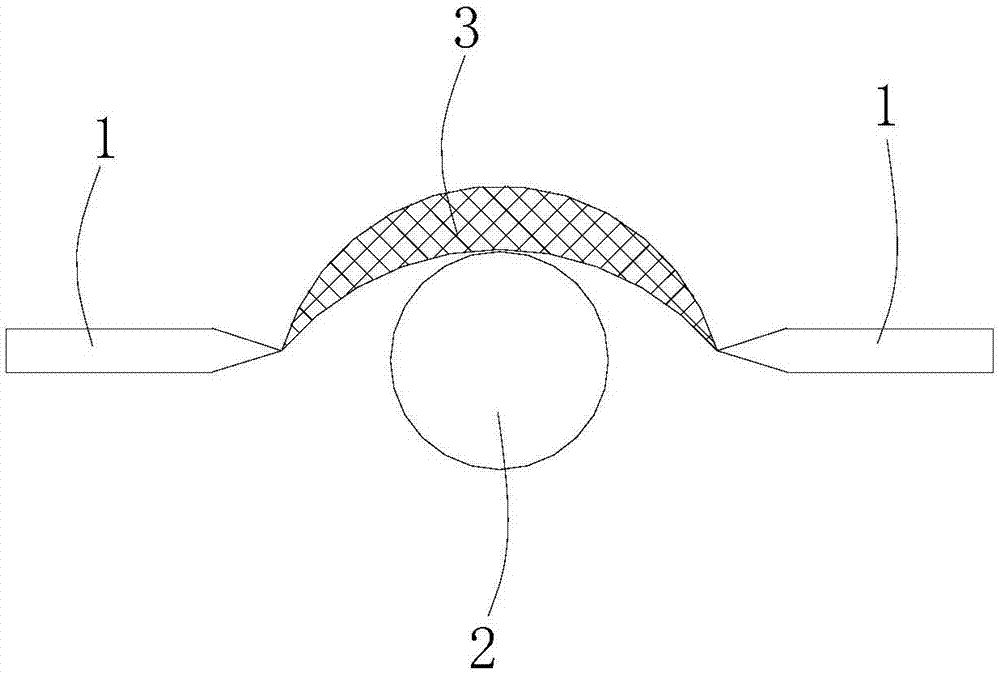

[0016] When in use, the four electrode rods 1 are energized, an arc discharge area 3 is generated between the tips of the four electrode rods 1 , and the end face of the large-diameter optical fiber 2 is placed in the arc discharge area 3 .

[0017] What has been described above is only one embodiment of the present invention. It should be pointed out that for those of ordinary skill in the art, some modifications and improvements can be made without departing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com