Multi-nozzle flow stabilizing and distributing device for strip continuous casting

A multi-nozzle and continuous casting technology, which is applied in the field of flow distribution devices for thin strip continuous casting, can solve problems affecting normal operation and continuous casting strip steel quality, increased fluctuations in molten pool liquid level, and unstable molten steel flow, etc., to achieve Reduce the occurrence of defects, reduce liquid level fluctuations, and improve the effect of flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

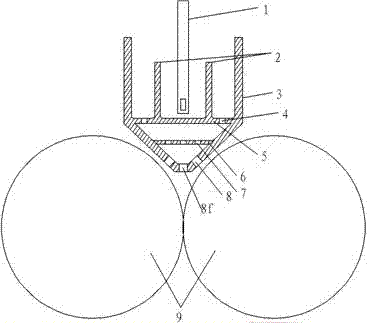

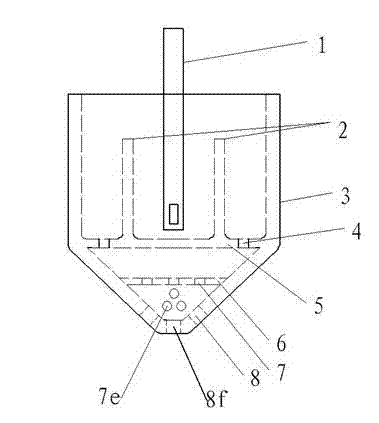

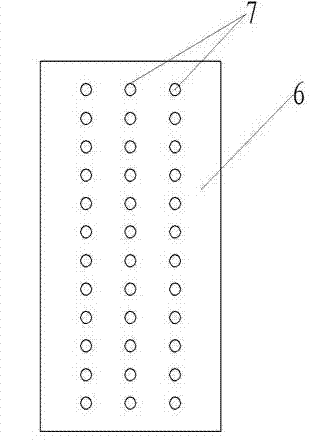

[0031] see Figure 1 to Figure 5 , a multi-nozzle steady flow distribution device for thin strip continuous casting, including a flow distributor 3 arranged above the molten pool at the front end of the initial metal solidification interface, and the metal melt is injected into the flow distributor through a group of submerged nozzles 1 at the bottom of the tundish 3, and then through the flow distributor 3, it enters the molten pool at the front end of the initial metal solidification interface, and the molten pool at the front end of the initial metal solidification interface is surrounded by double-rotating rollers 9 and side sealing plates. The cavity of the flow distributor 3 is also connected with the cavity of the flow stabilizer 2, the cavity of the flow stabilizer 2 is located above the cavity of the flow distributor 3, and the submerged nozzle 1 is immersed in the cavity of the flow stabilizer 2 In the metal melt, the metal melt is injected into the cavity of the cur...

Embodiment 2

[0039] This embodiment is basically the same as the first embodiment of the present invention, the difference is:

[0040] see Figure 6 , in this embodiment, the bottom horizontal base plate 5 of the current stabilizer 2 is also provided with 1 to 4 rows of shunt holes 4d, and each row of shunt holes 4d is also arranged along the roll width direction of the double-rotating roller 9, Each distribution small hole 4d is interlaced with any one of the flow guide holes 7 . Opening holes on the bottom horizontal base plate 5 of the current stabilizer 2 can increase the flow rate of molten metal output from the current stabilizer 2 to the flow distributor 3, improve the diversion capacity under a certain flow stabilization effect, and improve the efficiency of continuous casting.

[0041] In Embodiment 1 and Embodiment 2, the submerged nozzle 1 includes 2 to 4 nozzles, and the submerged nozzle 1 is arranged in the shape of a "one" along the roll width direction of the double-rotati...

Embodiment 3

[0044] This embodiment is basically the same as the first and second embodiments of the present invention, the difference is that:

[0045] see Figure 7 , in this embodiment, the shape of the submerged nozzle 1 is any one of the double-sided hole straight nozzle 1a, the bifurcated nozzle 1b or the straight nozzle 1c or any combination of different shapes. Specifically, it can be determined according to the process conditions. For example, the submerged nozzle 1 used can be composed of a straight nozzle 1c and a double-sided hole nozzle 1a. Submerged nozzles 1 of different shapes can be used according to needs, which can achieve a good effect of stabilizing the flow of molten metal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com